Constant-current driving electronic transformer

An electronic transformer, constant current drive technology, applied in the field of electronic transformers, can solve the problems of no protection function, short-term, electronic transformer and lamp damage, etc., to achieve the effect of simple circuit, constant output current, and increased lamp life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

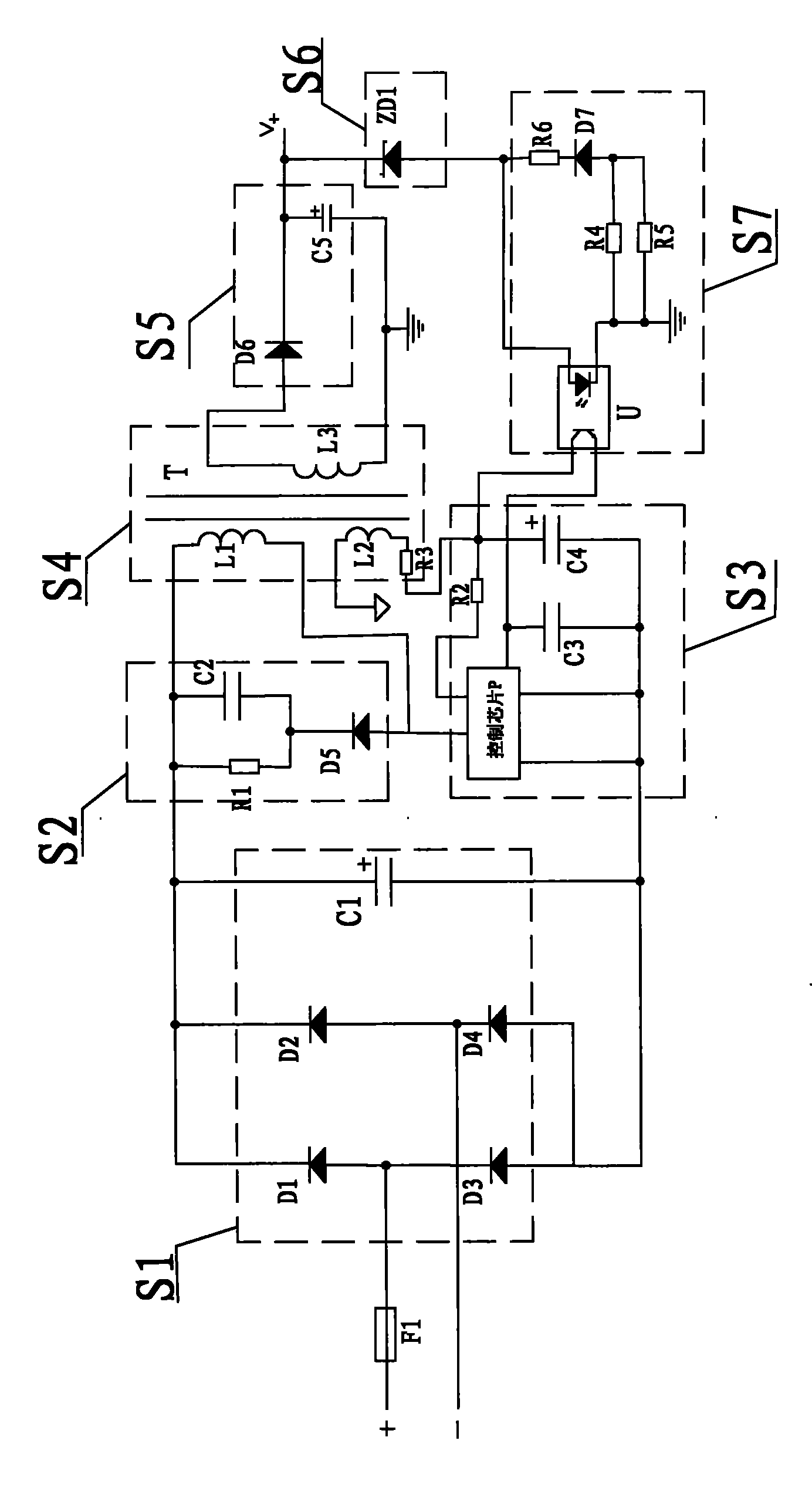

[0026] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

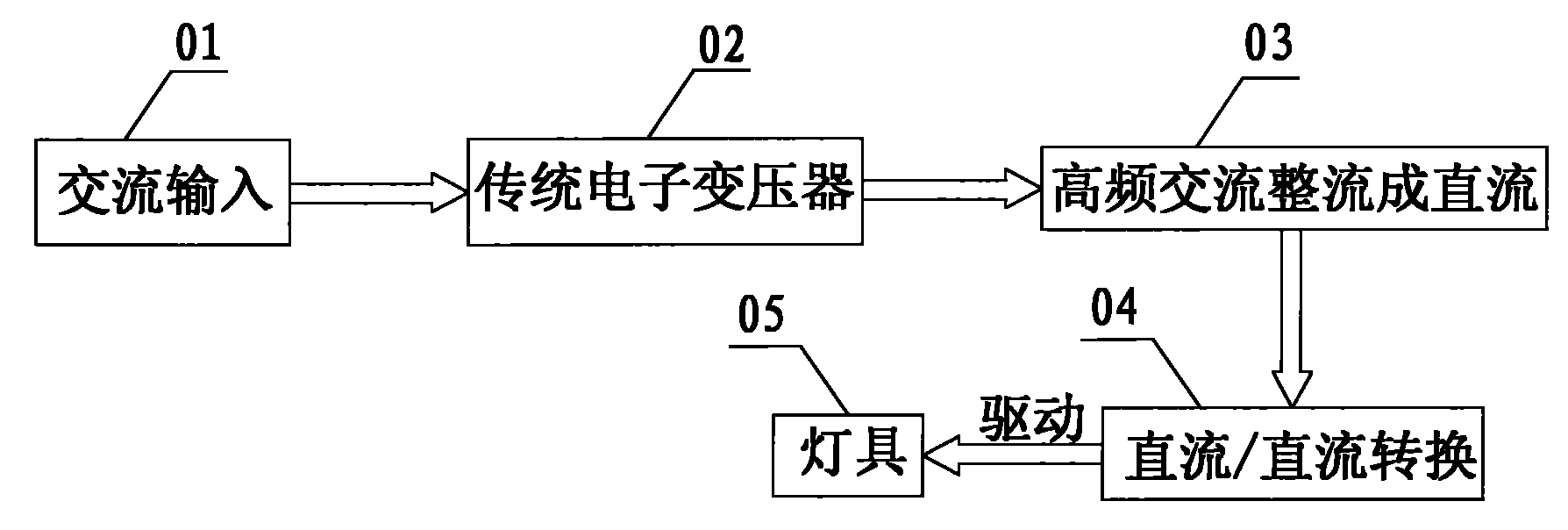

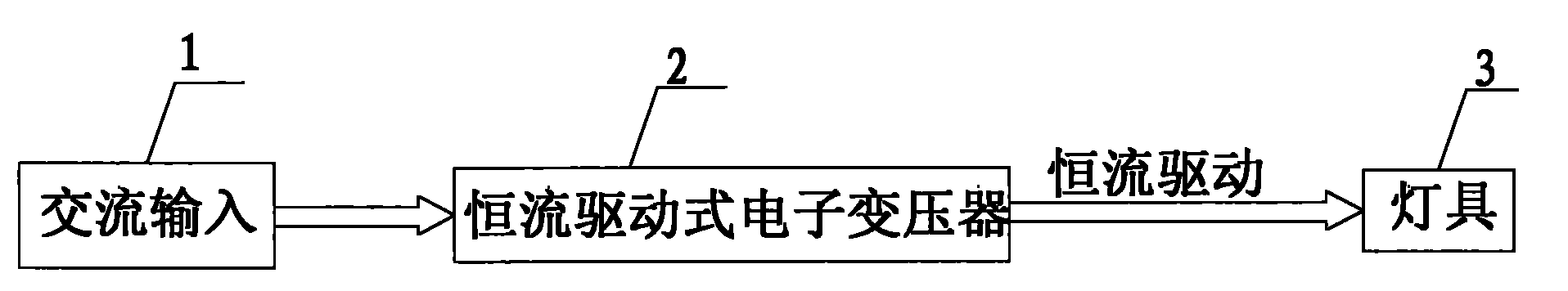

[0027] see figure 1 , the scheme of traditional electronic transformer driving lamps is: firstly, the AC input 01, 220V AC enters the traditional electronic transformer 02, and then the high-frequency AC is rectified into DC 03 through the transformer, and then the DC / DC conversion 04 process is carried out. This process consists of The DC / DC conversion chip completes the DC conversion, and finally drives the lamp 05. The whole process is realized in two stages. First, the power frequency AC is converted into high frequency AC, and then converted into DC. The circuit is complex; the output voltage is easy to change, the current is unstable, and the lamps are easy to flicker, and there is no overvoltage and overheating protection circuit in the tra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com