Method for tightly fitting heat pipe with heat sink

A heat sink and heat pipe technology, applied in the field of its tight connection, can solve problems such as gaps, low production capacity, and loss of adhesion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

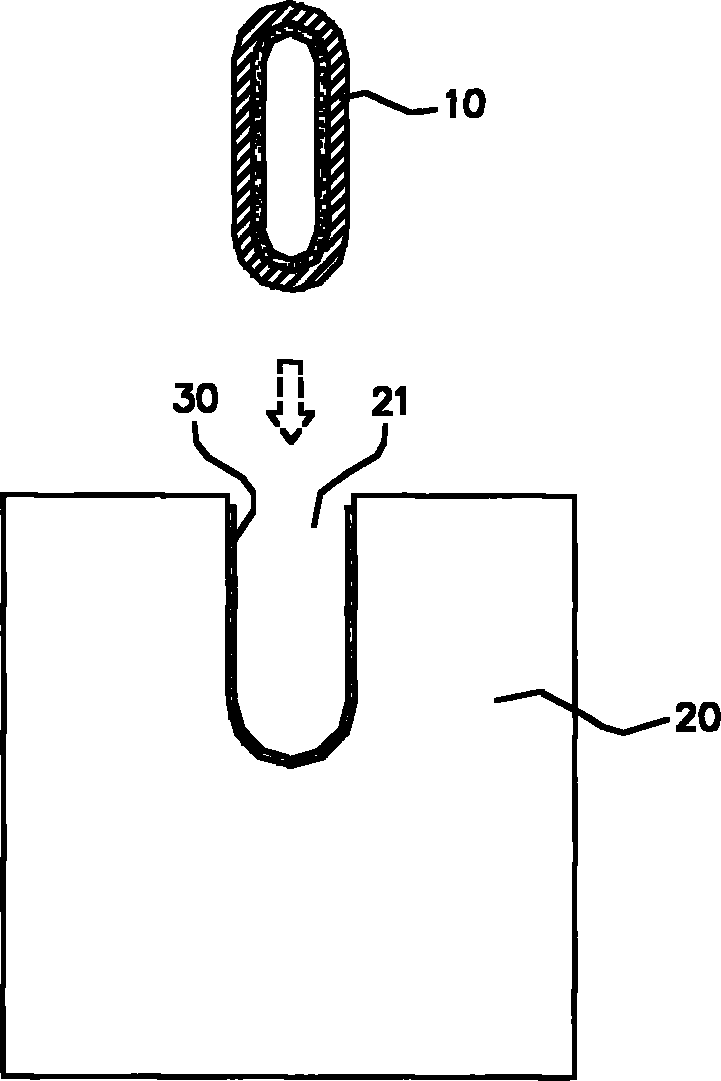

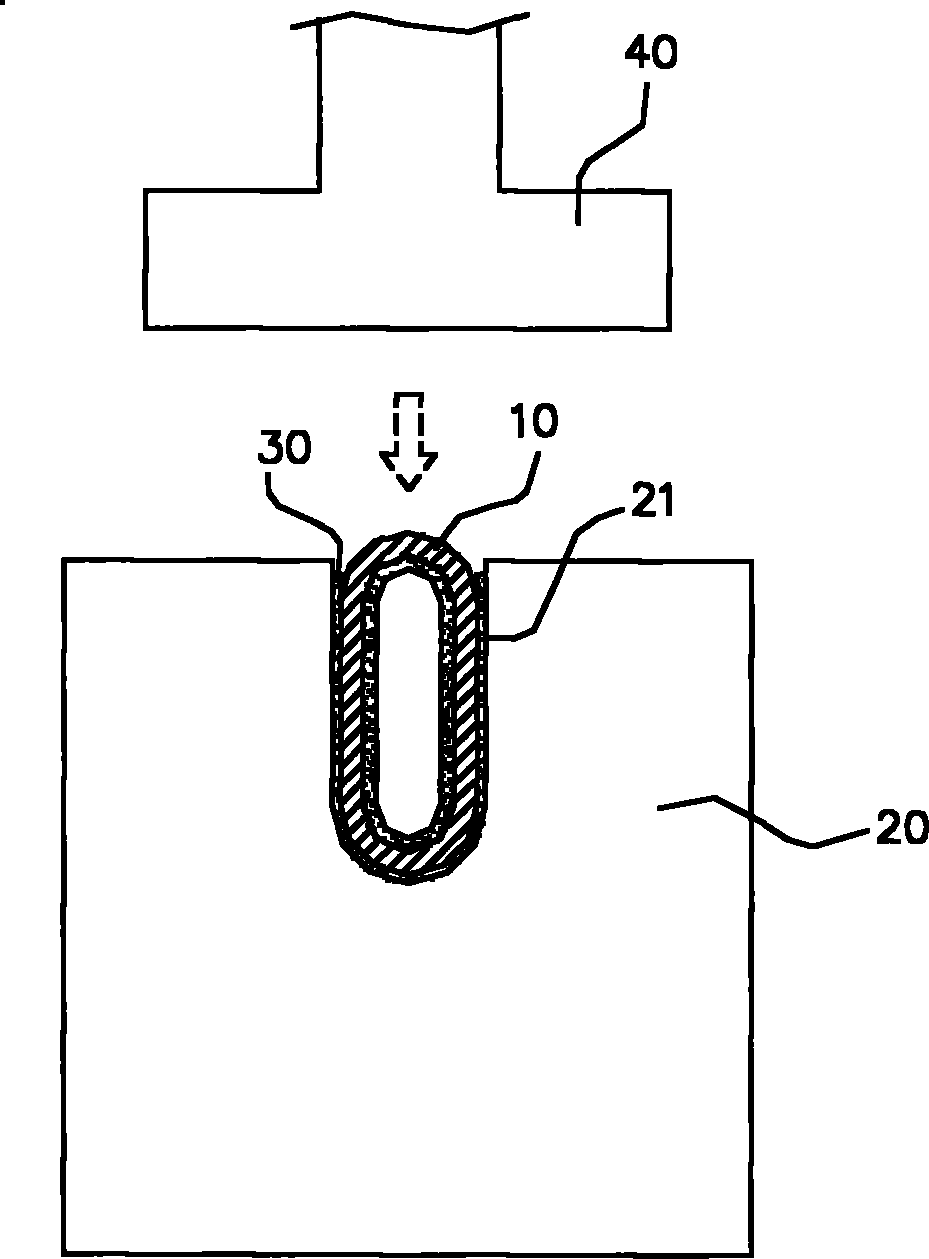

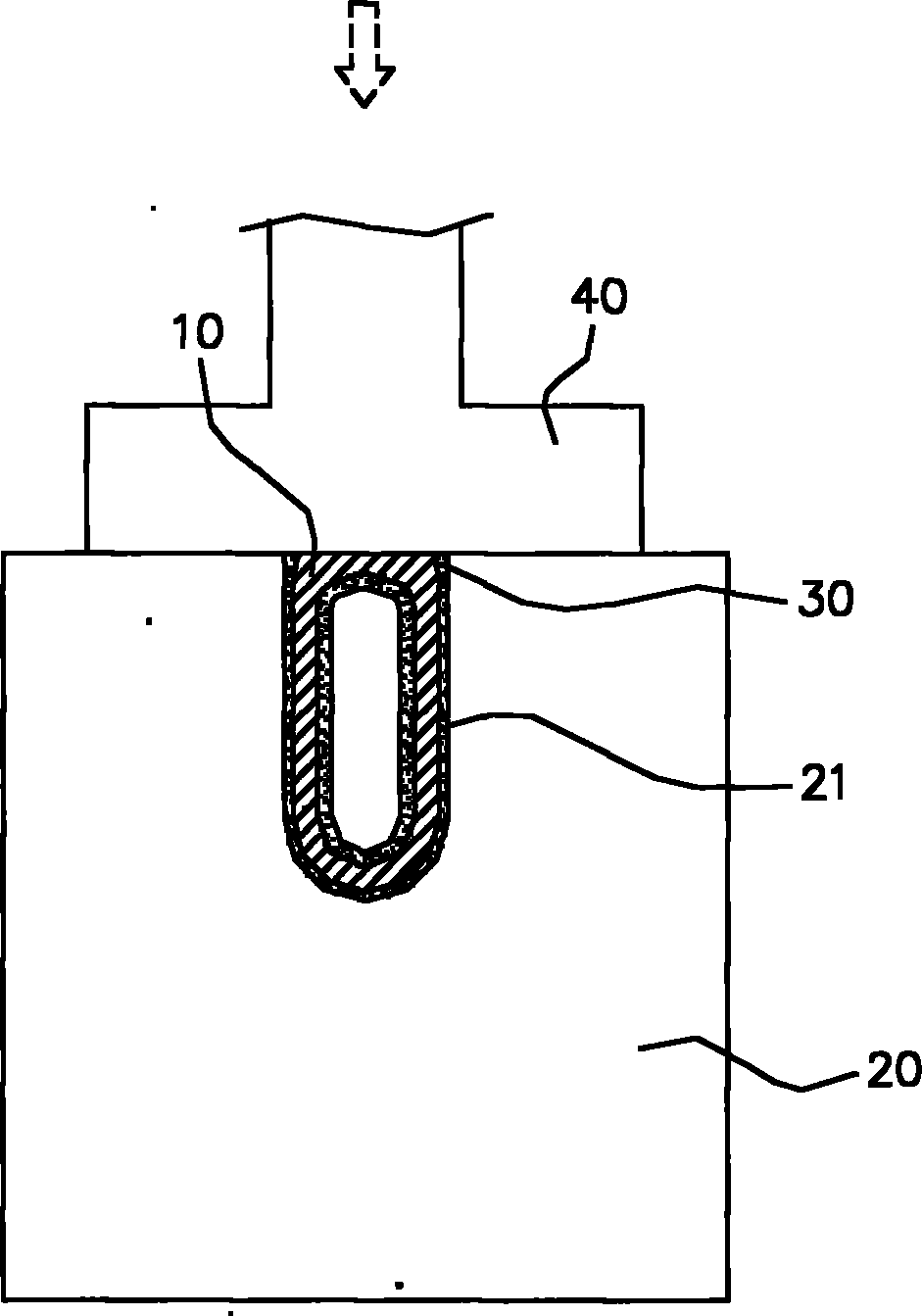

[0027] See first Figure 1A -D is the first embodiment of the present invention, which is a method for tightly fitting a heat pipe and a radiator, comprising the following steps:

[0028] a), provide at least one heat pipe 10, the heat pipe 10 is slightly shoulder-shaped or oblong, and slightly protrudes from the surface of the radiator 20, and a radiator 20 for conducting heat with the heat pipe 10, the radiator 20 is Any one of the heat conduction plate, the heat conduction base or the fin module, and a U-shaped groove 21 for accommodating the heat pipe 10 is provided on one side of the radiator 20;

[0029] b), placing the heat pipe 10 in the groove 21, and coating the heat-conducting medium 30 on its joint surface, and preparing a stamper 40; c), pressing the stamper 40 corresponding to the heat pipe 10 in the groove 21, One end of the heat pipe 10 is stamped and applied by the die 40, causing the heat pipe 10 to be deformed, and then pressed and tightly integrated with th...

no. 3 example

[0033] continued see Figure 3A -E, is the third embodiment of the present invention, a method for tightly fitting a heat pipe and a radiator, comprising the following steps:

[0034] a), provide at least one heat pipe 50, the heat pipe 50 is slightly oblate or oblong, and a radiator 60 for conducting heat with the heat pipe 50, the radiator 60 includes a plurality of fins 61, and on these The fin 61 is provided with a through hole 62 for providing and accommodating the heat pipe 50;

[0035] b), insert the heat pipe 50 into the aforementioned through hole 62, and coat the heat-conducting medium 70 on its combined joint surface, position the heat pipe 50 section between the two fins 61 on the jig 80, and prepare a die 82;

[0036] c) Punch the die 82 corresponding to the jig 80 to stamp the heat pipe section between the two fins 61, the heat pipe section located at both ends of the fin 61 is pressed by the die 82 and bulges toward the through hole 62 of the fin 61 deformatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com