Direct power control with component separation

A controller and power output technology, applied in vector control systems, control systems, control generators, etc., can solve problems such as wear and high mechanical components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

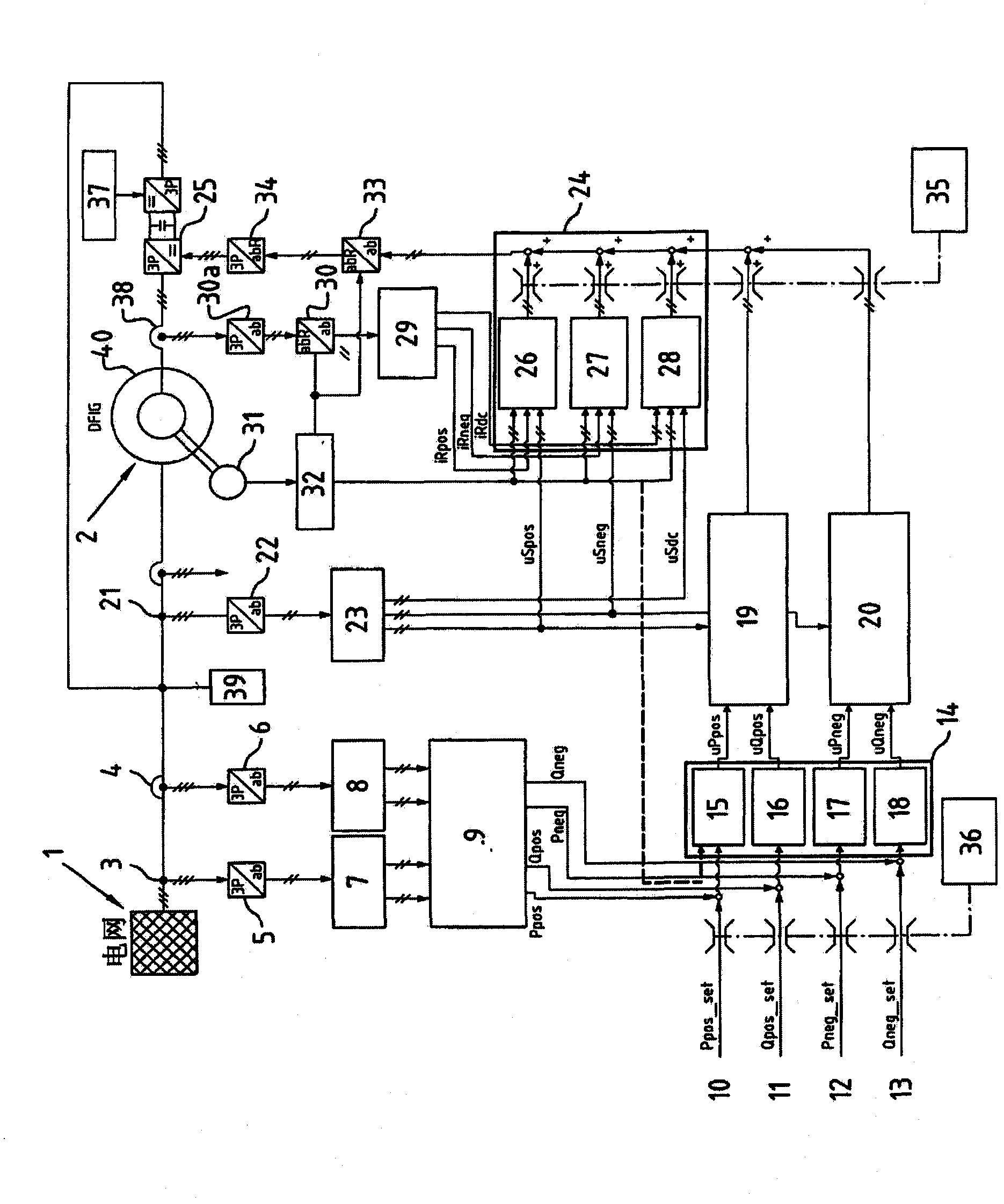

[0028] first, figure 1 A utility grid 1 and a doubly-fed induction machine 2 abbreviated DFIG are shown. In order to provide the method of the invention, means are shown for measuring the grid voltage 3 and the grid current 4, both in a three-phase system. Thereafter, the measured grid voltage and grid current are transformed into the stator frame coordinate system ab by means of the means 5 , 6 . Derived from the stator frame coordinate system, the positive and negative sequence systems are defined and the measured voltage and current values are transformed into these two systems.

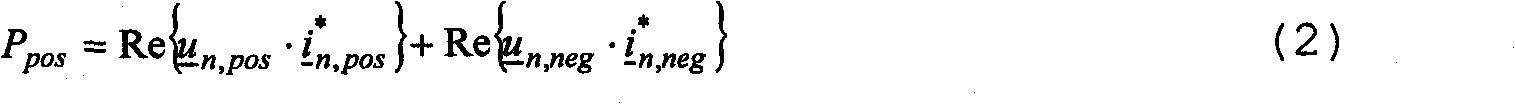

[0029] Typically, the voltage and current vectors in a positive sequence system circulate at 50 Hz, 60 Hz respectively in the mathematical forward direction, while these vectors in a negative sequence system also circulate at 50 Hz, 60 Hz respectively in the opposite direction. In blocks 7 , 8 the components of the positive-sequence and negative-sequence systems of the measured grid voltage 3 an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com