Garment with patterns and making method of garment

A production method and pattern technology, which is applied in the field of clothing manufacturing, can solve the problems of destroying the normal physiological functions of the human body, disturbance, and high dye content in fabrics, and achieve the effect of rich three-dimensional layering and dynamics, large visual impact, and reduced dye content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] Embodiment 1 makes sweatpants with patterns

[0046] 1. Lay the original fabric with the sky blue pattern and the adhesive on a flat press, set the pressure at 0.5Mpa, and the temperature at 165°C, heat and press the original fabric with the pattern and the adhesive to obtain a patch.

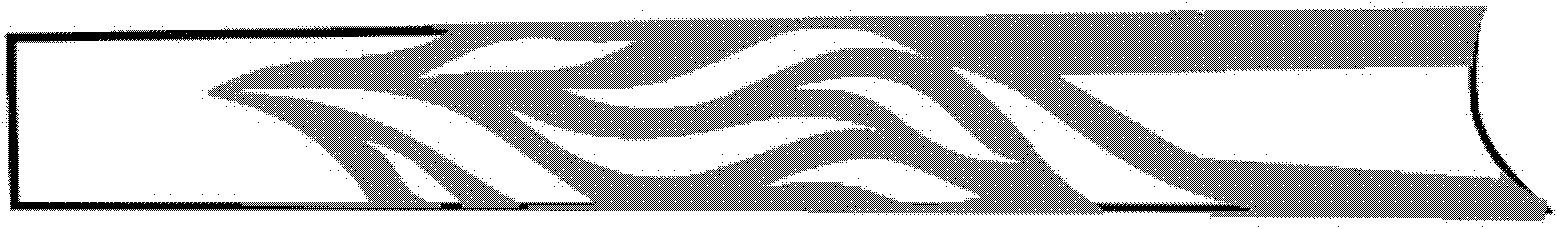

[0047] 2. Put the patch prepared in step 1 on the laser machine processing table, output processing instructions from the computer, and laser cut the patterned shape and knife edge of the patch to obtain the pattern patch. See figure 2 Shown is an illustration of the shape of the graphic applique.

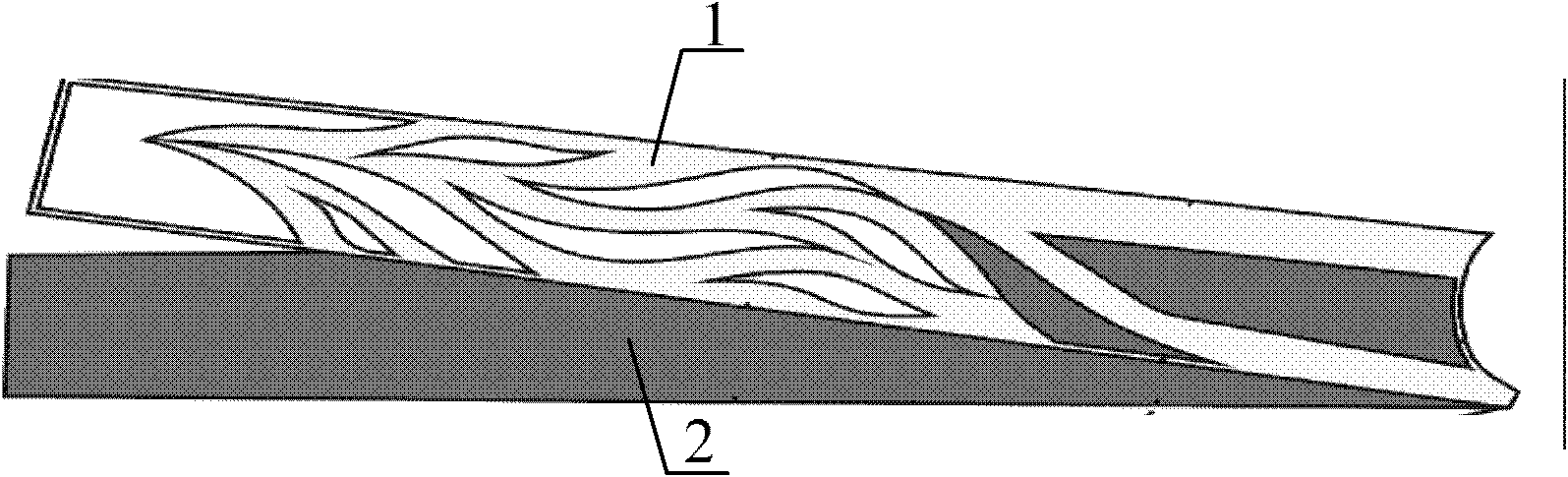

[0048] 3. See image 3 Shown is the lamination diagram of the pattern patch and the cut piece. Place the dark blue piece 1 flat on the positioning table, take the pattern patch 2 prepared in step 2, and align the patch 2 and the cut piece 1 according to the knife edge position. Fitting, the adhesive layer of the pattern patch is in contact with the cut piece; after lamination, first use a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com