Orthodontic force measuring device

A measuring device and orthodontic technology, which is applied in dentistry, medical science, etc., can solve the problems of reducing the effect of orthodontic treatment, delaying treatment time, and difficult internal measurement, so as to shorten the time of orthodontic treatment, improve the treatment effect, and broaden the development prospects Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

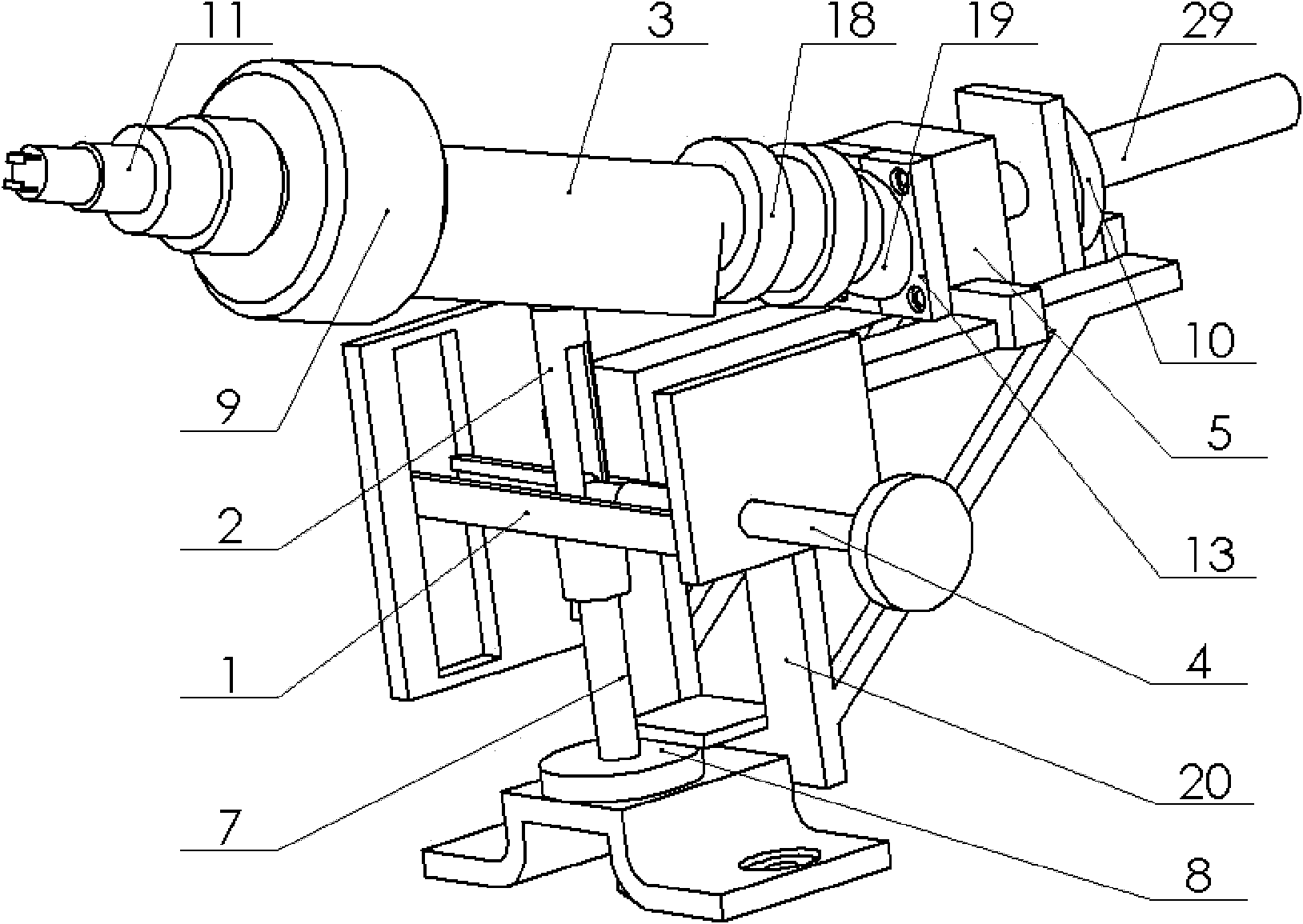

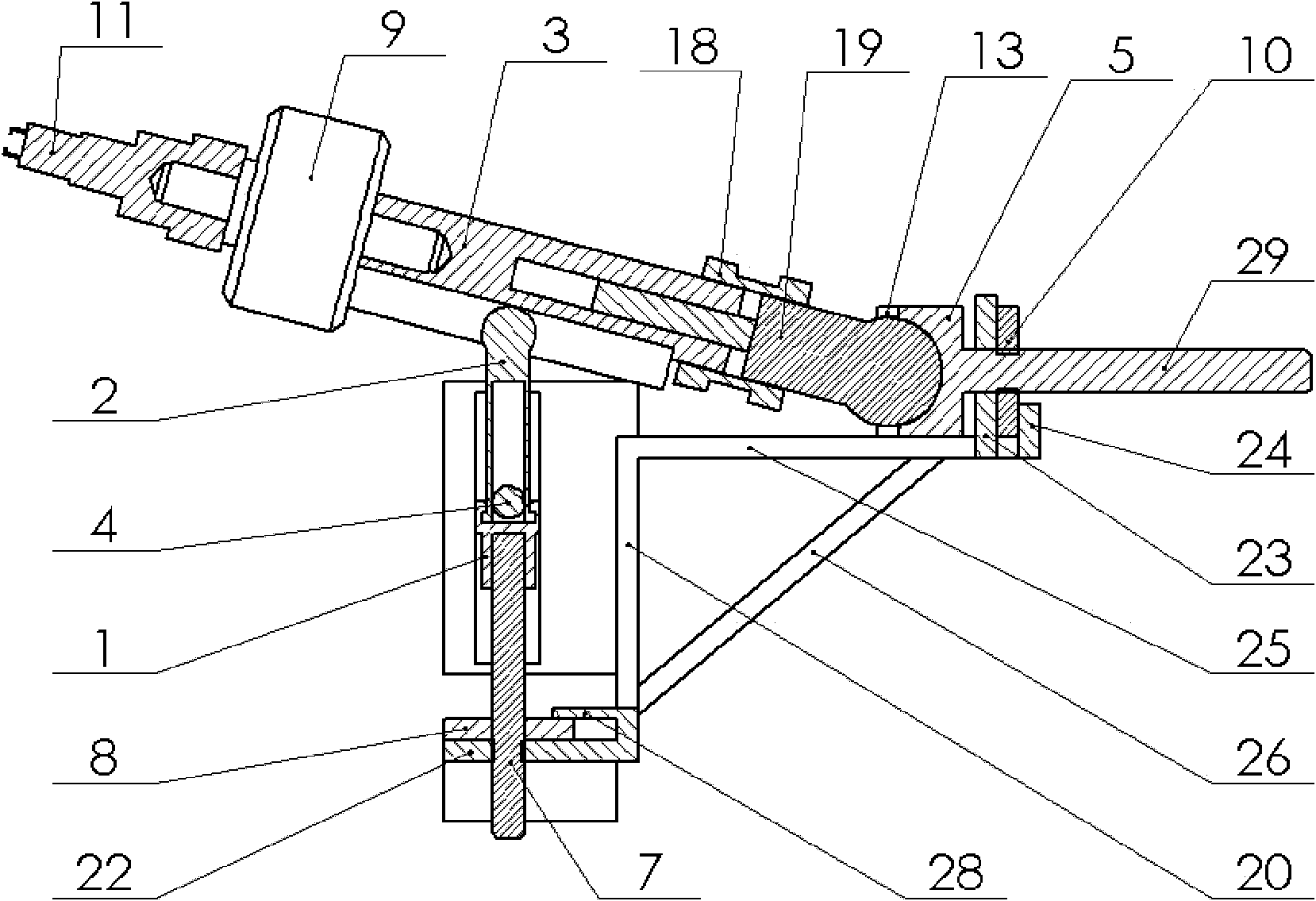

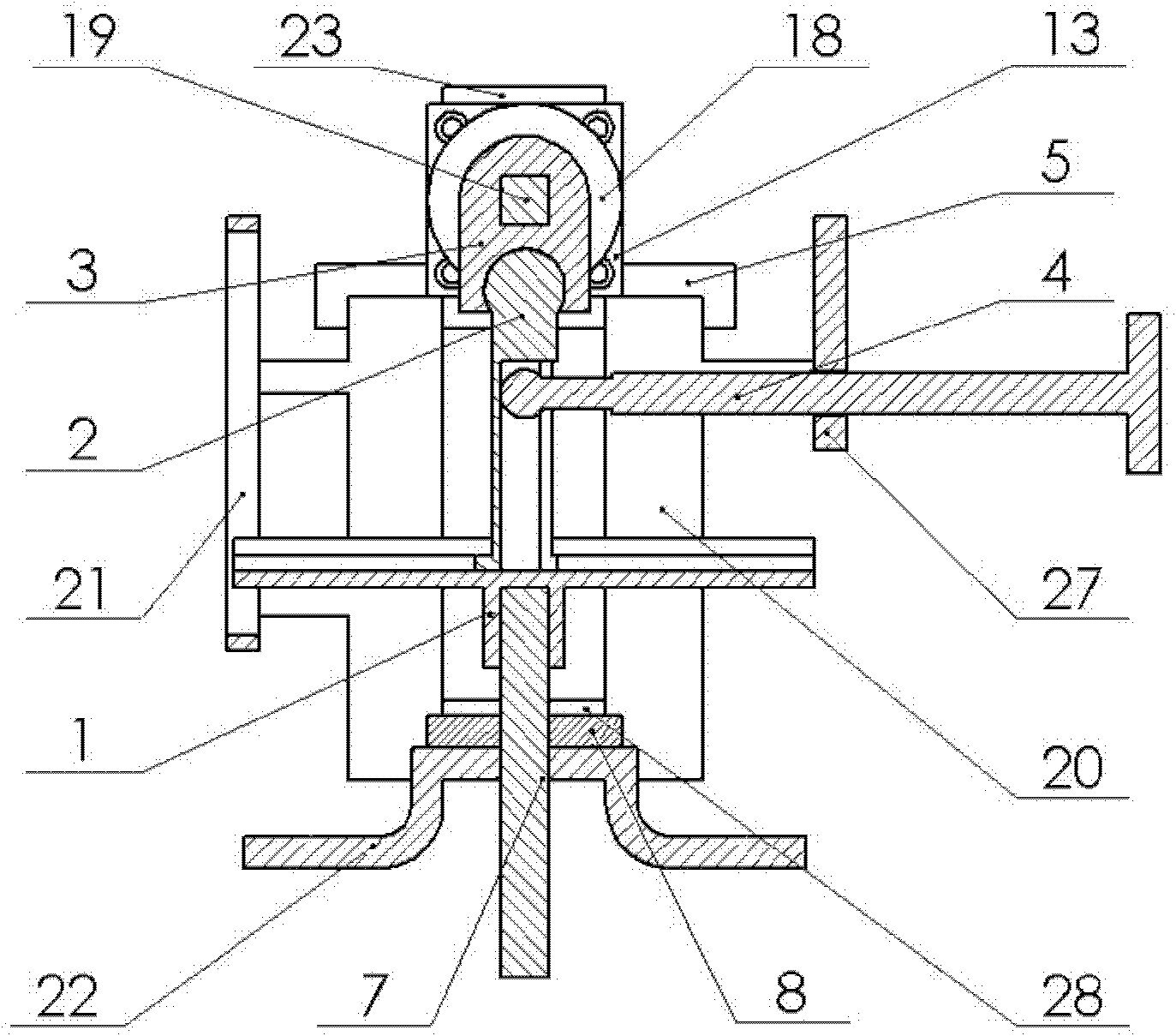

[0024] The present invention will be further described below in conjunction with the accompanying drawings of the description.

[0025] The orthodontic force measuring device for orthodontics of the present invention includes a base, an adjustment module and a measurement module; the base includes a vertical riser 20, and the lower part of the riser 20 is connected with a base 22 and a lower stopper 28, The base 22 is in the shape of a "several" and includes a horizontal upper end surface and ear surfaces on both sides of the upper end surface. The upper end surface is provided with round holes, and the two ear surfaces are provided with round holes. A bayonet is formed between the upper end surfaces of the vertical plate 20; the two sides of the vertical plate 20 are respectively connected with a square groove baffle plate 21 with a vertical square groove and a screw hole baffle plate 27 with a screw hole; the upper end of the vertical plate 20 is connected with a horizontally...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com