Method and device for stably forming all-position welding pool

An all-position welding and molten pool technology, applied in welding equipment, metal processing equipment, manufacturing tools, etc., can solve the problems of low efficiency, small average current, easy flow of molten pool, etc., and achieve large welding current, high efficiency, and complete welding Effective positional effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Further describe the present invention below in conjunction with embodiment:

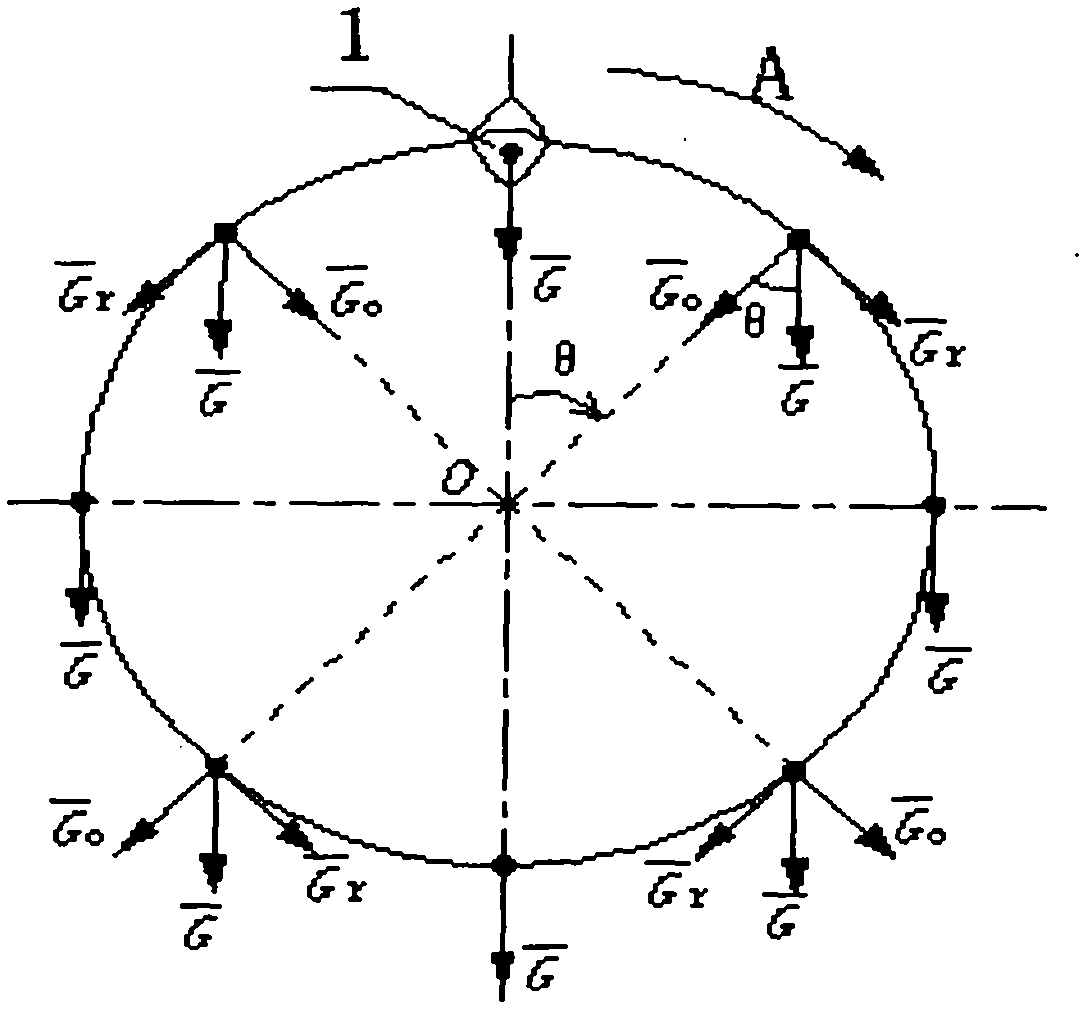

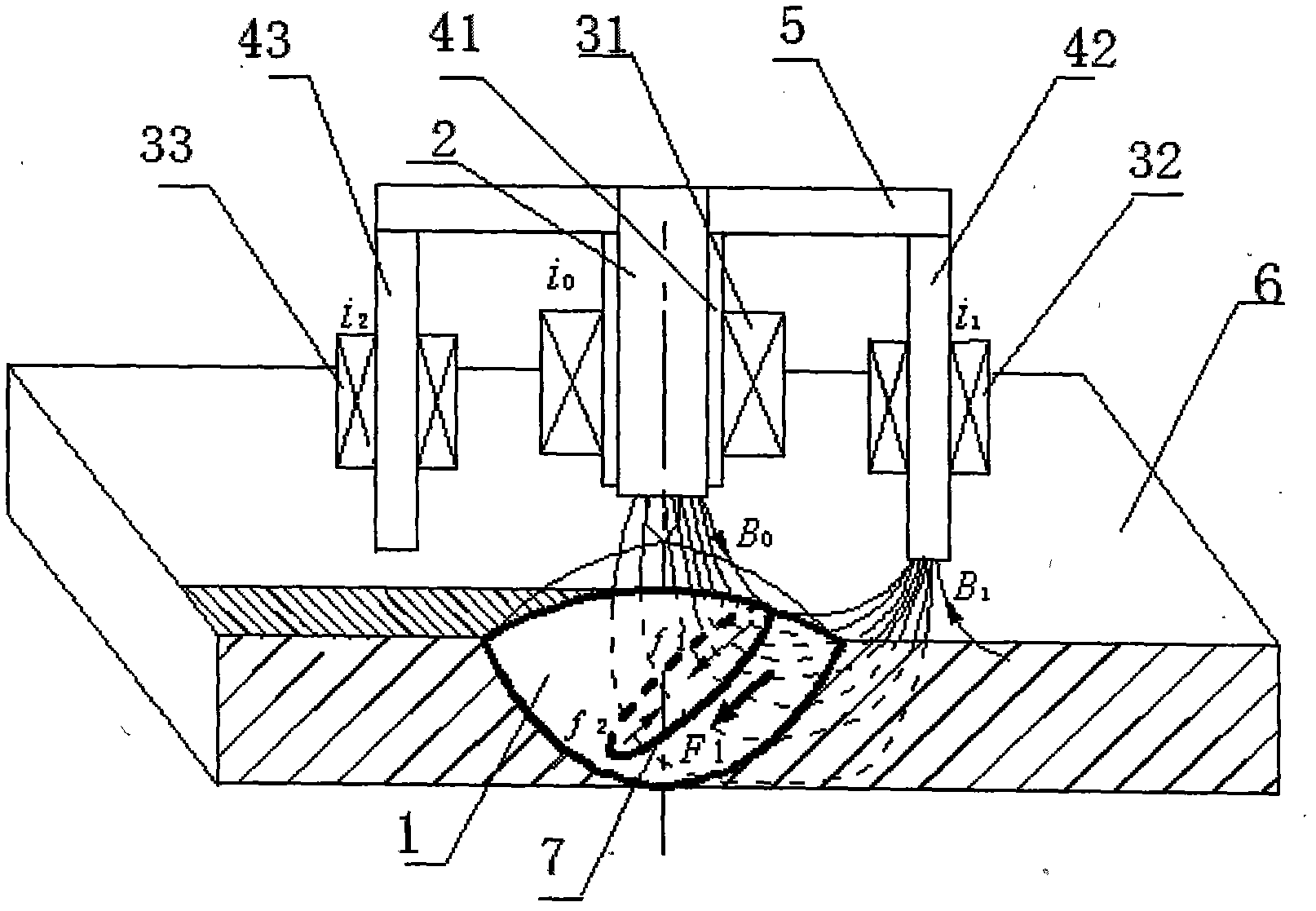

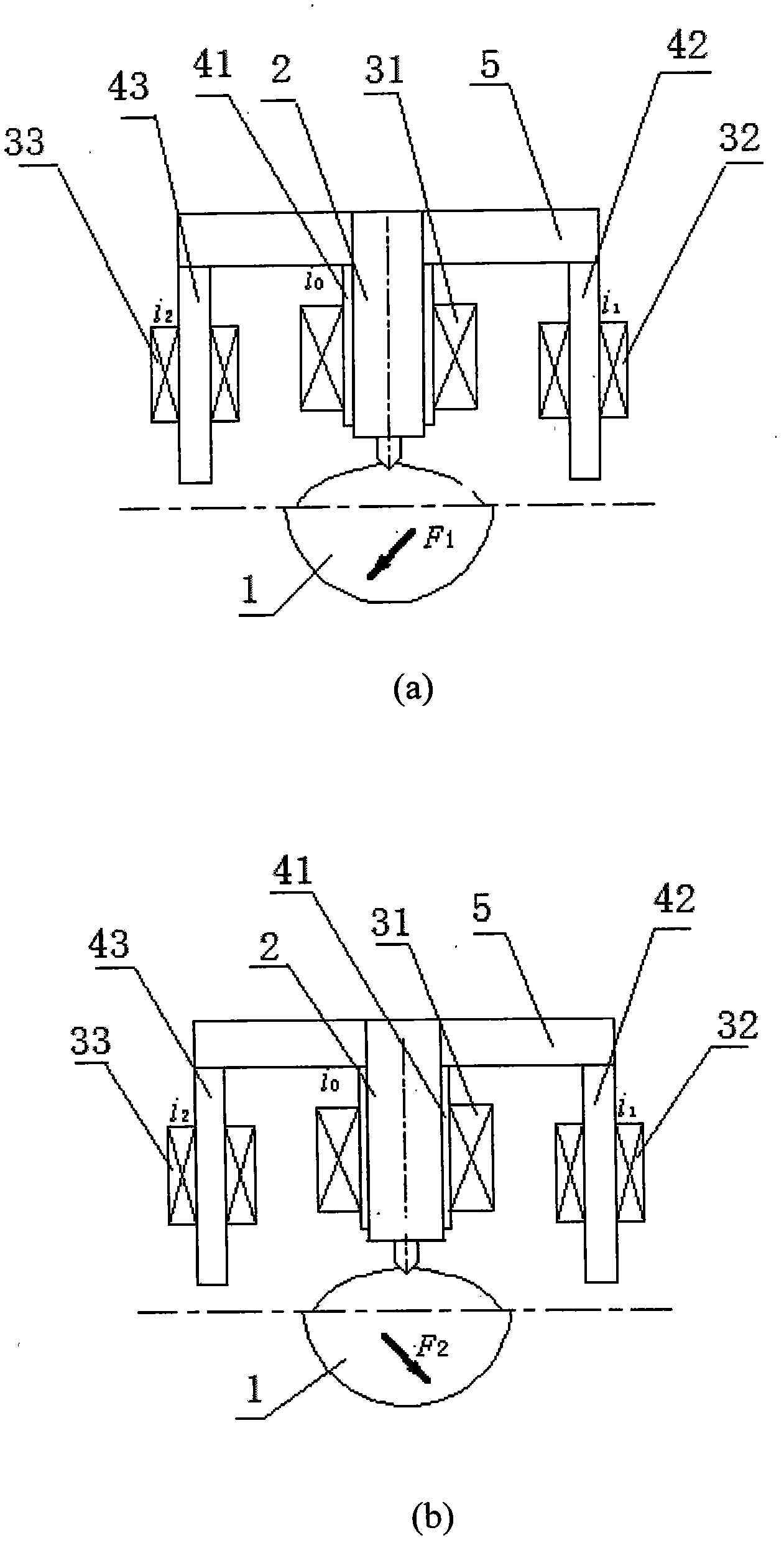

[0016] The method (abbreviation method, see Figure 1-6 ), the method consists of the left coil 33-middle coil 31 and the middle coil 31-right coil 32 to form a left-right symmetrical external high-frequency alternating magnetic field, which is installed on the welding torch 2, so that the molten iron in the welding pool can generate eddy currents, And make the eddy current interact with the external high-frequency alternating magnetic field to generate electromagnetic force, use the generated electromagnetic force to offset part or all of the gravity that affects the stable formation of the weld pool, and maintain the stable formation of the weld pool in all positions The number of turns of each coil is 20 to 200 turns respectively, and the center distance between the left coil and the middle coil and between the middle coil and the right coil is symmetrically called 50mm to 150mm, and the e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Number of turns | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com