Device for quickly dismounting skid driving wheel of automobile production line

A technology for an automobile production line and a dismantling device, which is applied in the field of tooling and fixtures, can solve the problems of reducing production efficiency, complicated operation, narrow space, etc., and achieves the effects of easy processing, ensuring production efficiency, and convenient operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

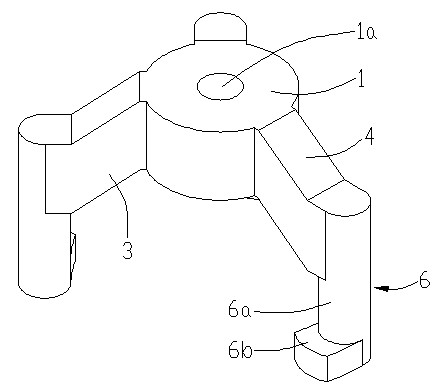

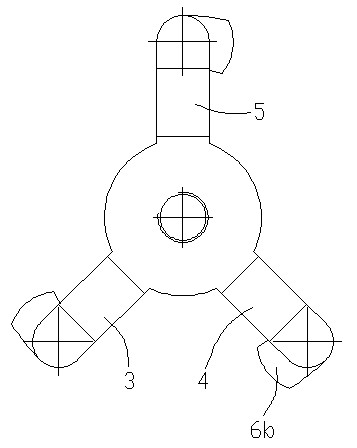

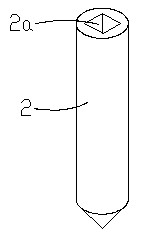

[0018] Such as figure 1 , figure 2 , image 3 As shown, the present invention is made of base 1, thimble 2, first cantilever 3, second cantilever 4, third cantilever 5 and grabbing hook 6, and wherein base 1 is a short cylindrical structure, at the axis of base 1 A threaded hole 1a is formed, and the threaded hole 1a penetrates the upper and lower end surfaces of the base 1 . A thimble 2 is pierced in the threaded hole 1 a of the base 1 , the thimble 2 is a cylinder with external threads, and the thimble 2 and the base 1 are screwed together. The lower end of the thimble 2 is tapered with a large top and a small bottom. A square hole 2a is formed on the top of the thimble 2 along the axis of the thimble. The shape and size of the square hole 2a are adapted to the output shaft of the pneumatic ratchet wrench.

[0019] From figure 1 , figure 2 It can be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com