Automatic punching and tapping transmission mechanism for rubber dark chamber

A technology of conveying mechanism and glue dark box, which is applied in metal processing machinery parts, other manufacturing equipment/tools, metal processing, etc., can solve the problems of poor processing accuracy, low production efficiency of manual operation, high labor cost and production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

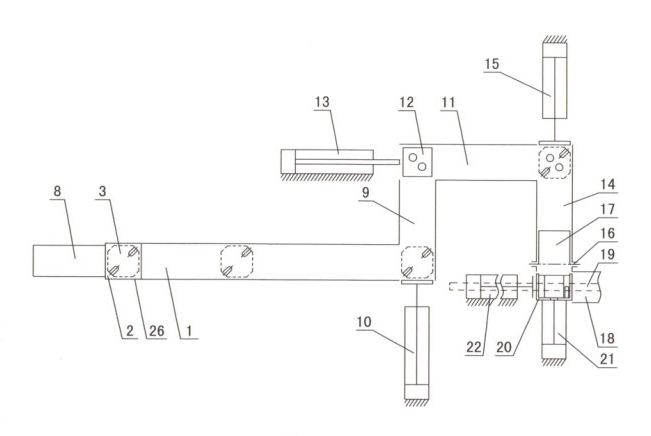

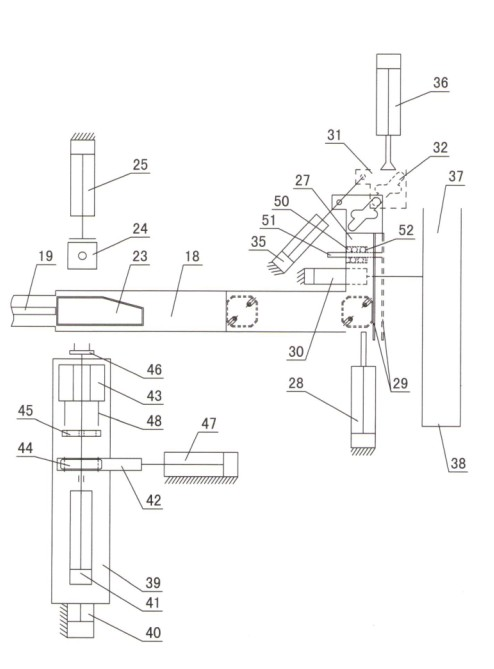

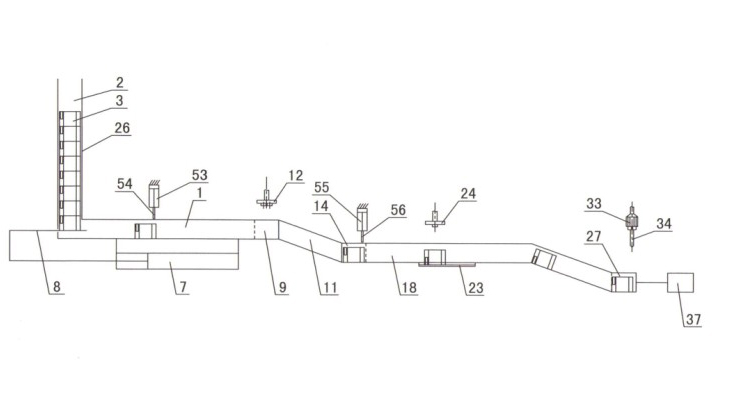

[0011] The invention relates to an automatic stamping and tapping conveying mechanism for a glue dark box, such as Figure 1-Figure 4As shown, it is characterized in that it includes a frame, on which the first horizontal groove 1 is installed, and a feeding bracket 26 is installed on the front end of the first horizontal groove, and a feeding port 2 is opened on the feeding frame, and a glue dark box is placed in the feeding port 3. The rubber dark box is composed of the bottom surface 4, four side surfaces 5 and threaded holes 6. The pushing cylinder A7 is installed under the first horizontal groove 1. The piston rod of the pushing cylinder A is connected to the push plate 8, and the push plate is connected to the glue dark box. Contact, the first horizontal groove 1 is connected to the first straight groove 9, and the pushing cylinder B10 is installed outside the connection between the first horizontal groove and the first straight groove, the first straight groove is connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com