Method for controlling static and dynamic liquid composite steering delay of caterpillar

A hysteresis control and vehicle technology, applied in the direction of fluid steering mechanism, etc., can solve problems such as pressure fluctuations of pump motors, achieve the effects of improving stability, prolonging service life, and saving fuel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

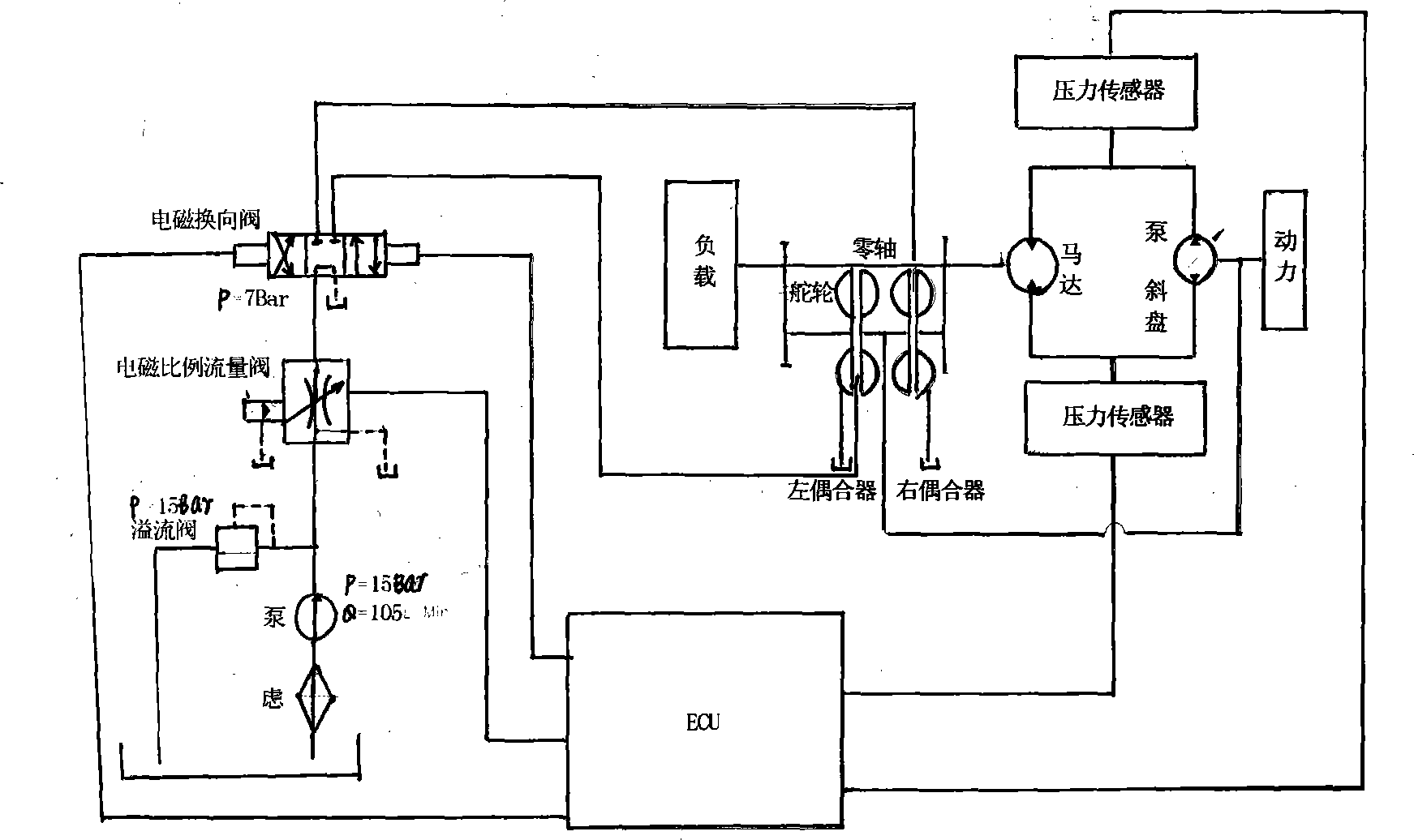

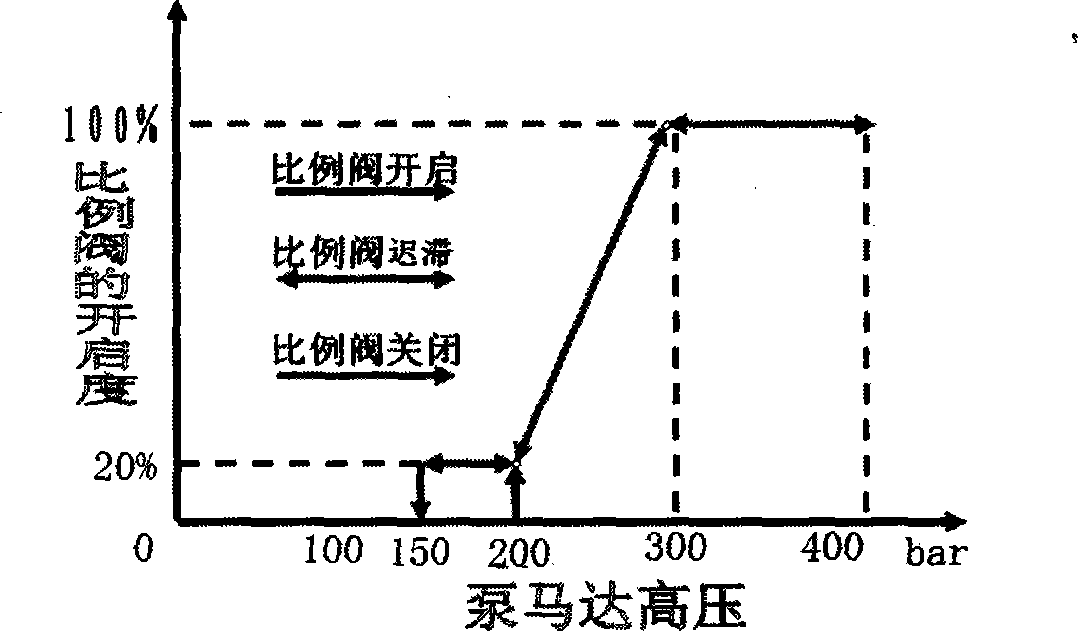

[0033] The static and dynamic fluid compound steering hysteresis control method of the tracked vehicle in this embodiment includes the following steps:

[0034] 1) Select the conjoined pump motor, zero shaft, coupling, load, proportional flow valve, electromagnetic reversing valve, relief valve and microprocessor; the conjoined pump motor is connected to the pressure sensor through the oil pipe, and the conjoined pump motor passes through The zero axis is connected to the load; the zero axis is connected to a coupling through the steering wheel, connected to the other coupling through the gear, and connected to the electromagnetic reversing valve through the oil pipe; the electromagnetic reversing valve is connected in series with the proportional flow valve through the valve plate, The electromagnetic reversing valve is connected in parallel with the overflow valve through the proportional flow valve; one end of the microprocessor is connected with the pressure sensor, and the...

Embodiment 2

[0055] The static and dynamic fluid compound steering hysteresis control method of the tracked vehicle in this embodiment includes the following steps:

[0056] 1) Select the conjoined pump motor, zero shaft, coupling, load, proportional flow valve, electromagnetic reversing valve, relief valve and microprocessor; the conjoined pump motor is connected to the pressure sensor through the oil pipe, and the conjoined pump motor passes through The zero axis is connected to the load; the zero axis is connected to a coupling through the steering wheel, connected to the other coupling through the gear, and connected to the electromagnetic reversing valve through the oil pipe; the electromagnetic reversing valve is connected in series with the proportional flow valve through the valve plate, The electromagnetic reversing valve is connected in parallel with the overflow valve through the proportional flow valve; one end of the microprocessor is connected with the pressure sensor, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com