Drain plate for preparing electronic grade spun yarns and electronic grade spun yarn preparation method

An electronic-grade, leak-proof technology, used in glass manufacturing equipment, manufacturing tools, glass production, etc., can solve the problems of difficult wire drawing, uneven single fiber diameter, and reduced product quality, and avoid uneven single fiber diameter. The effect of uniform distribution of glass filaments and increased product yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

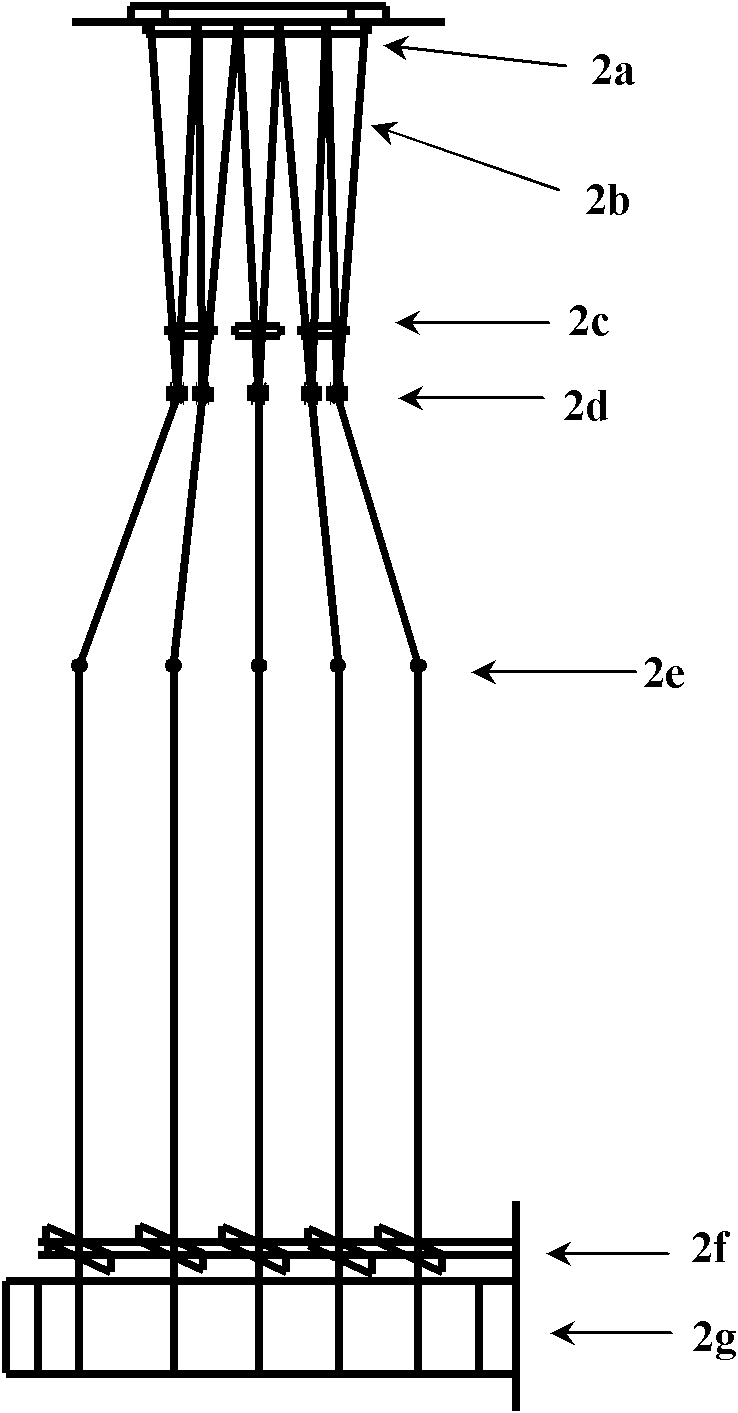

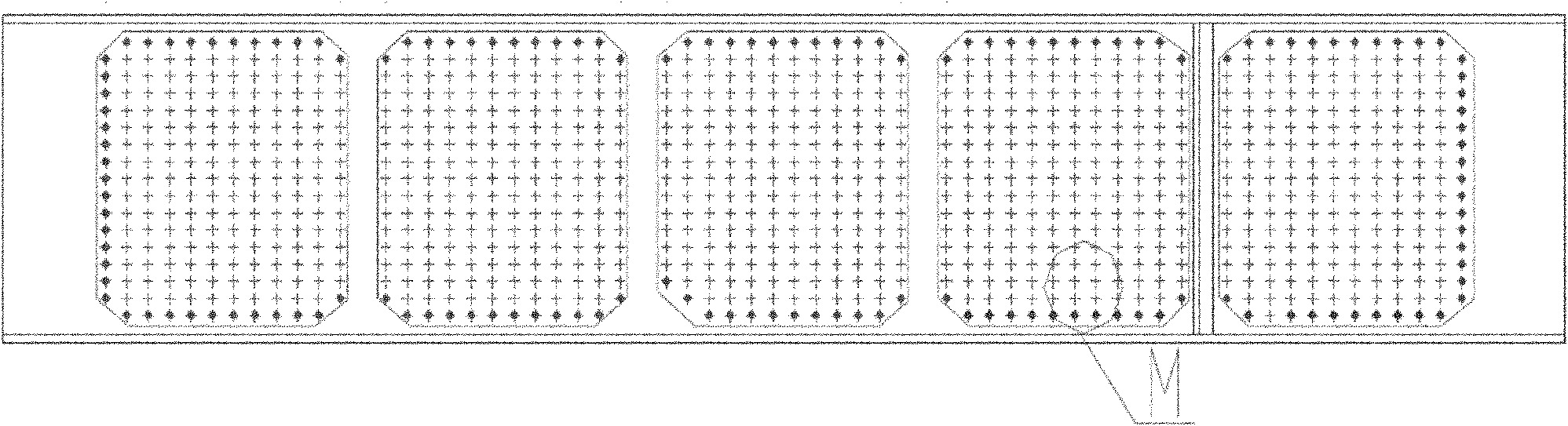

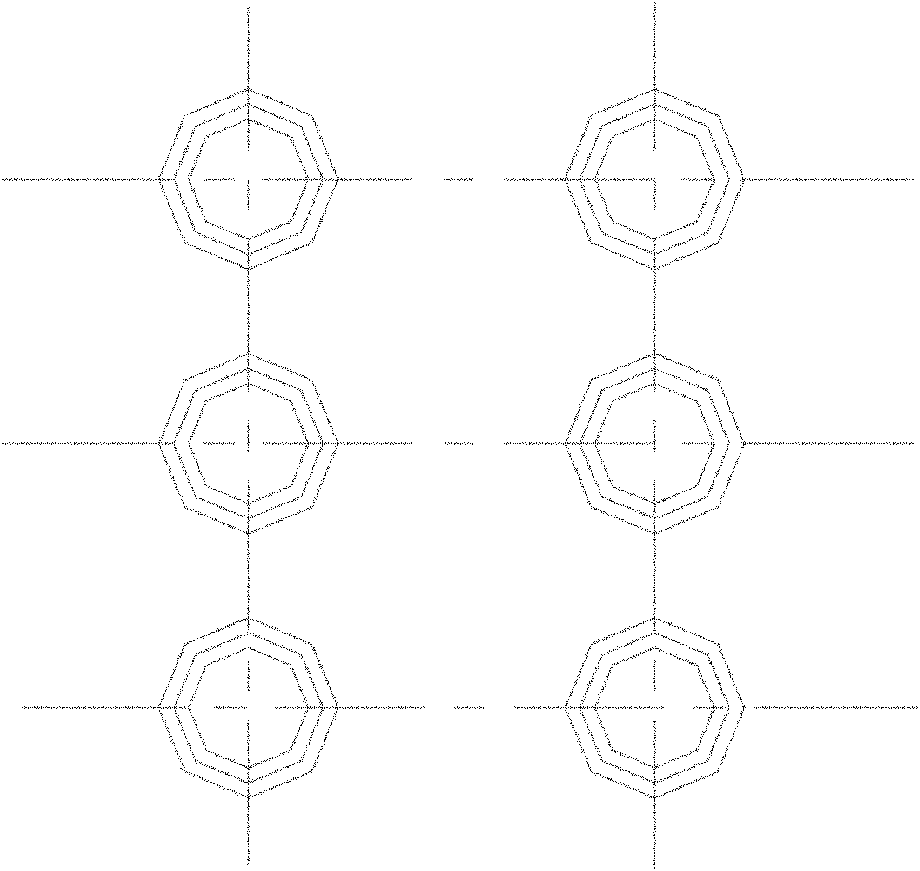

[0037] Figure 1a It is the layout diagram of the bushing plate of the present invention. The bushing is a single-layer bushing with a thickness of 1.7mm, which can prevent the deformation caused by the temperature difference between the upper and lower surfaces of the bushing. It can be seen from the figure that the leakage plate is divided into 5 areas with the same size, shape and distribution on average, and the leakage nozzles in each area are arranged in a rounded matrix with 12 columns and 17 rows, that is, each area is composed of 12 columns and 17 rows of leakage nozzles The matrix removes one leak in each of the four corners and has 200 leaks. Therefore, there are 1000 leaks in the 5 districts. Those skilled in the art can imagine that the arrangement of the nozzles on the bushing can be a certain form of arrangement in a parallelogram array w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com