Bushing for preparing industrial-grade spun yarns and industrial-grade spun yarn preparation method

An industrial-grade, spun yarn technology, which is applied in manufacturing tools, glass manufacturing equipment, glass production, etc., can solve problems such as lowering the quality of spun yarns, lowering product quality, and glass crystallization, so as to improve the layout of leak nozzles, increase production efficiency, and increase The effect of symmetry

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

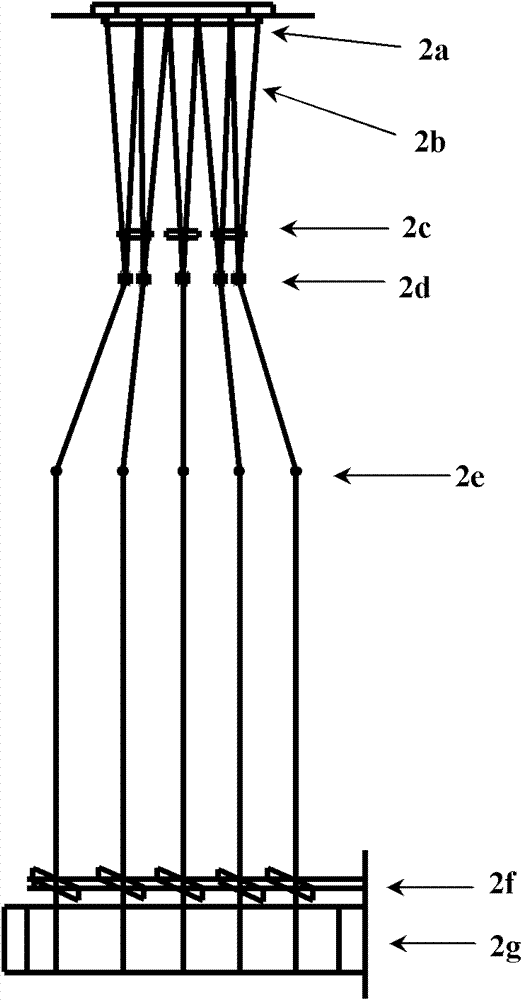

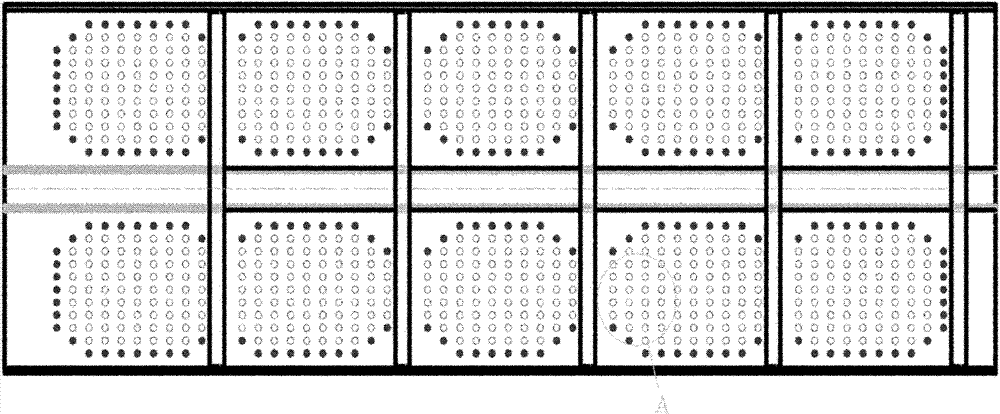

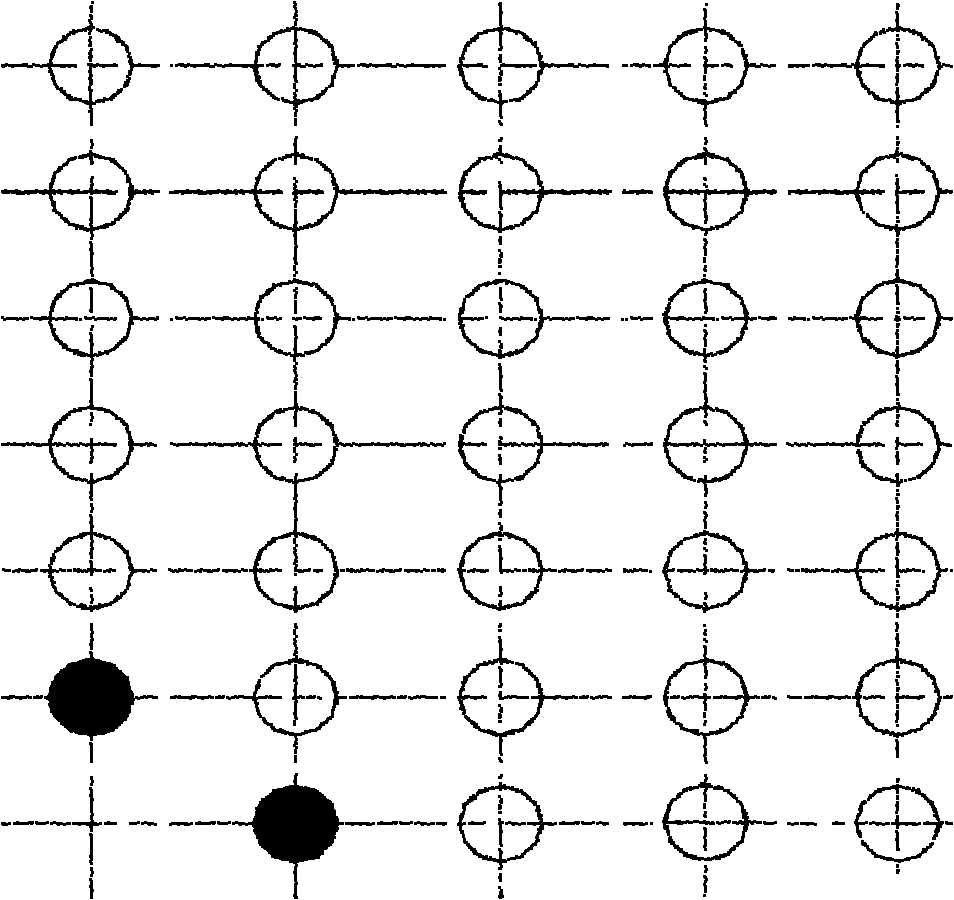

[0038] Figure 1aIt is the layout diagram of the bushing plate of the present invention. The bushing is a single-layer bushing with a thickness of 1.5mm, which can effectively prevent the deformation caused by the temperature difference between the upper and lower surfaces of the bushing. It can be seen from the figure that the base plate of the drain plate is divided into two rows of 5 parallel distributions with 10 different fillet matrices, including the two N arrays distributed in the middle of the base plate and symmetrical to the two N arrays. 8 said M arrays distributed axisymmetrically. The N array is a parallelogram array with 10 columns and 11 rows of rounded corners composed of leaks. The four corners of the four corners of the leaks are removed to form a parallelogram array with 98 rounded corners. The M array is a rounded corner of 10 colum...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com