Method for pouring house grade level

A pouring method and flooring technology, which is applied to floors, buildings, building structures, etc., can solve problems such as floor cracking, and achieve the effects of small force, guaranteed strength, and high construction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] In order to describe in detail the technical content, structural features, achieved objectives and effects of the present invention, the following description is combined with specific embodiments and illustrations.

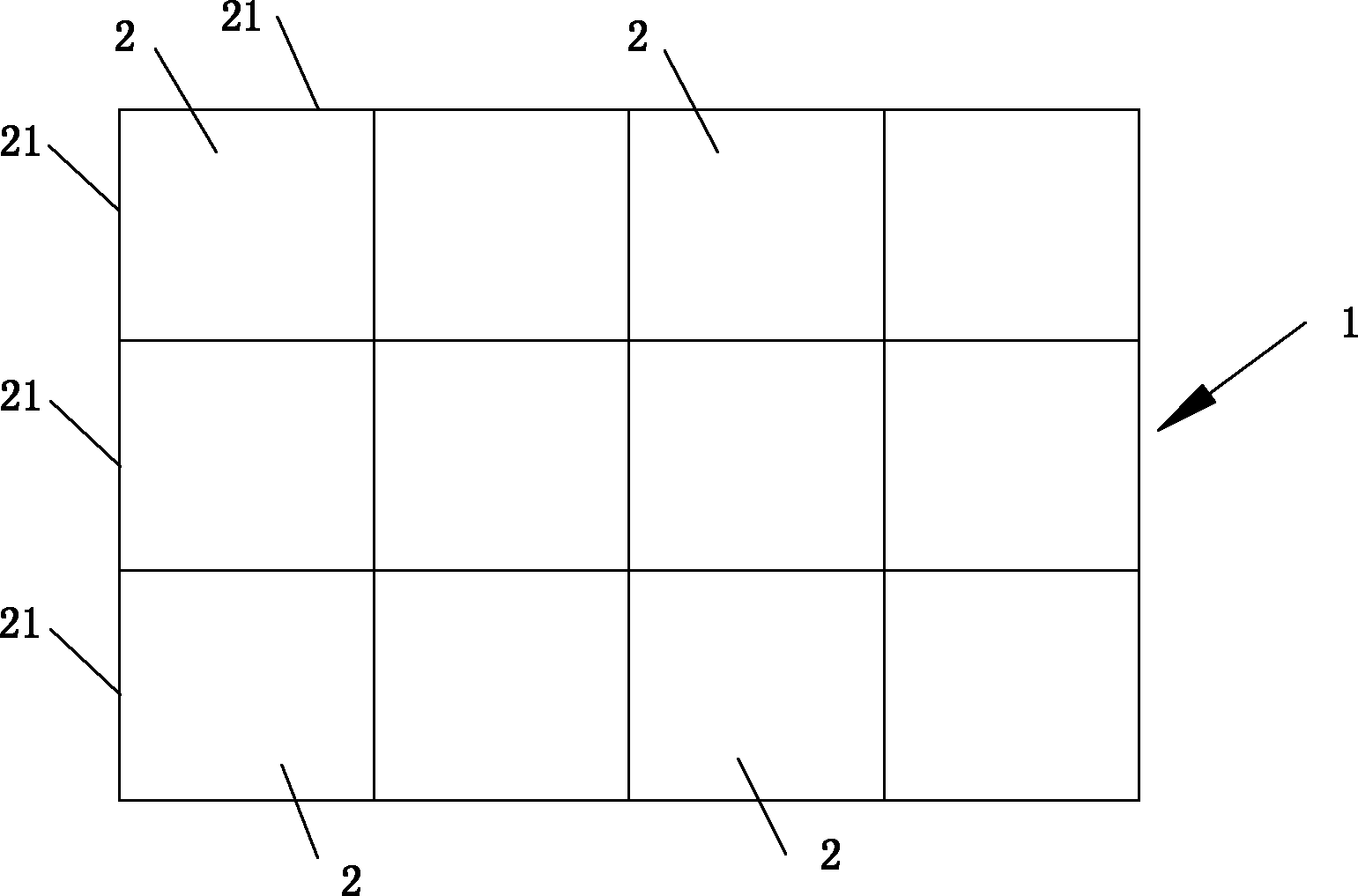

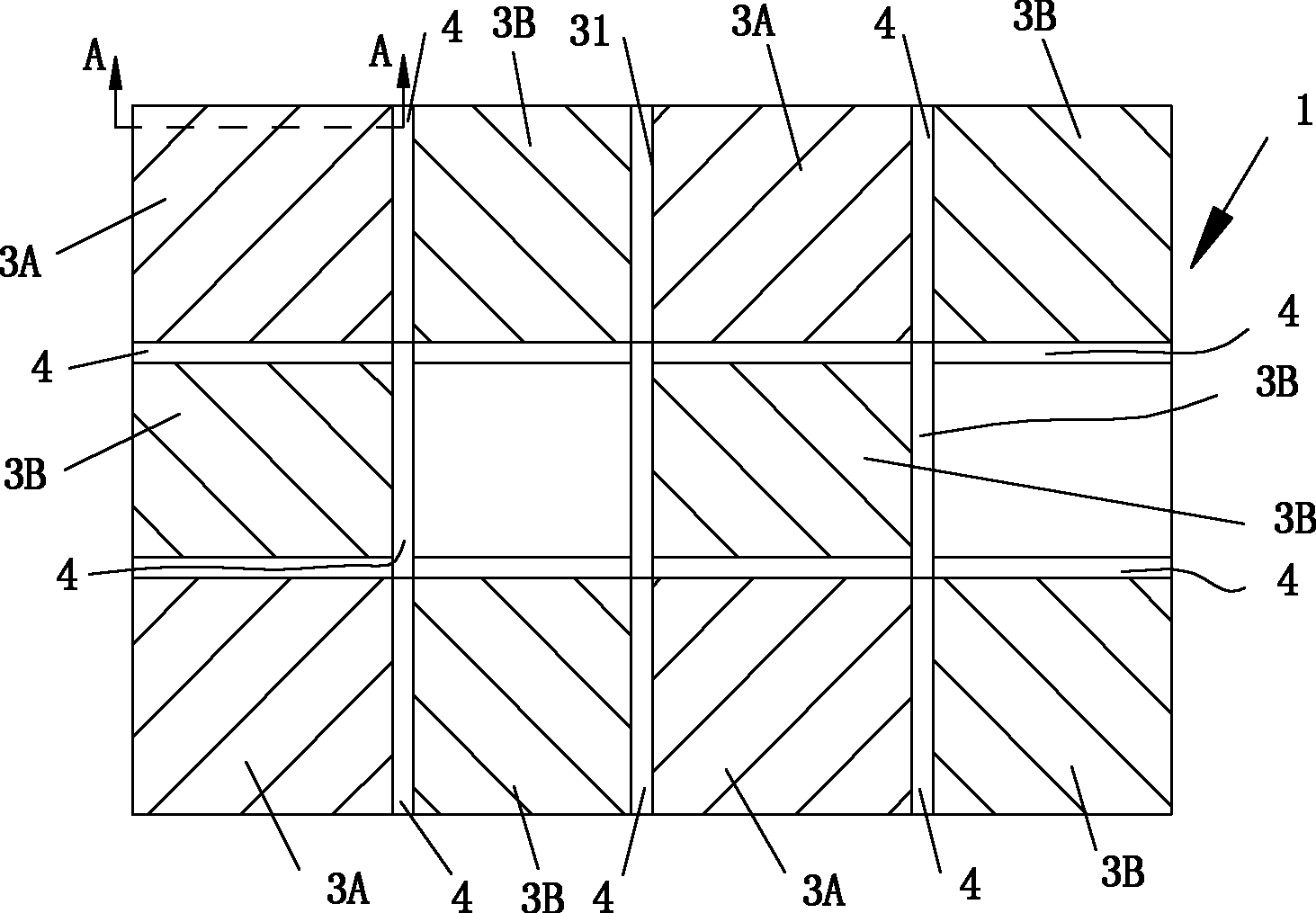

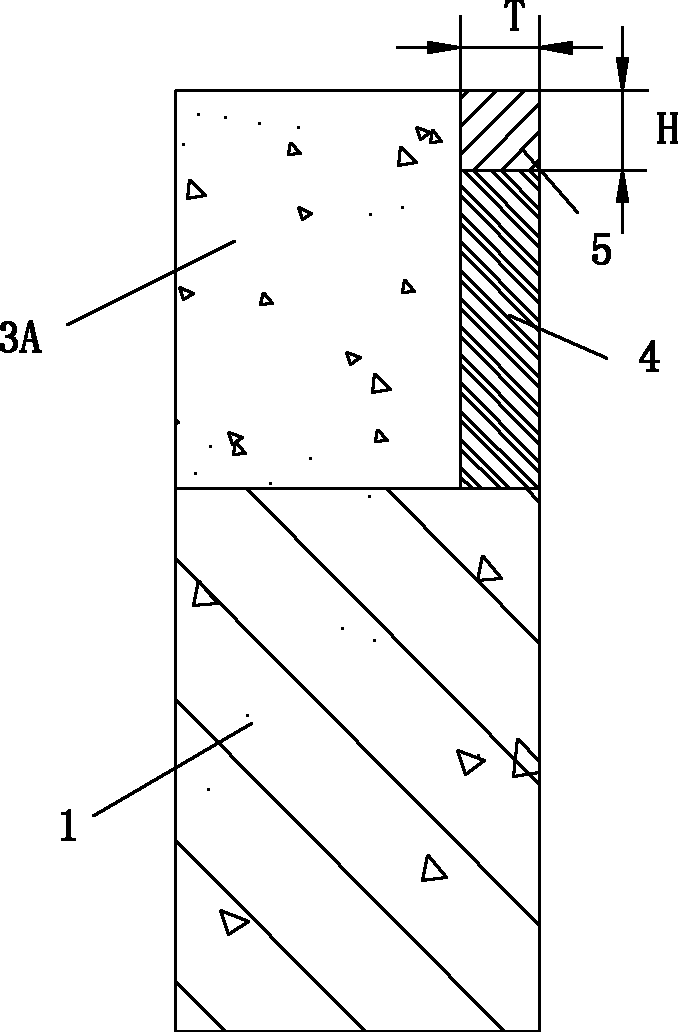

[0035] See figure 1 When implementing the technical solution of the present invention, firstly, the ground 1 of the house is divided into multiple casting areas 2. In this step, the way of division is different according to the area and shape of the ground. No matter what method is used, the ground 1 must be divided based on the beauty and the approximate area of each piece. For example, after calculating the area of each pouring area 2 reasonably, the ground 1 of the house is divided by elastic lines It is divided into multiple pouring areas 2, which are surrounded by multiple dividing lines 21, for example, figure 2 The casting area 2 in the first row and the first column shown is surrounded by four dividing lines 21. In the present invention, the divi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com