Method for filling heavy-pitch coal bed goaf

A goaf and steep inclination technology, applied in the fields of backfill, mining equipment, earthwork drilling, etc., can solve the problems of large consumption of pillars, unable to ensure the stability of the roof of the goaf, and not recovering pillars, etc. The effect of preventing sinking damage and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] An embodiment of the present invention will be further described below in conjunction with accompanying drawing:

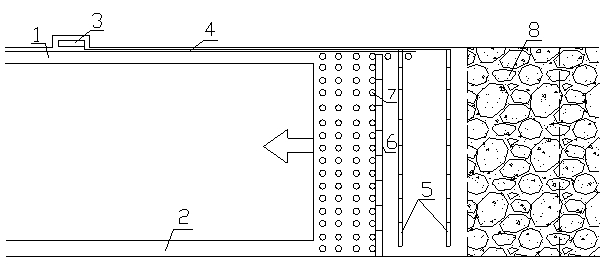

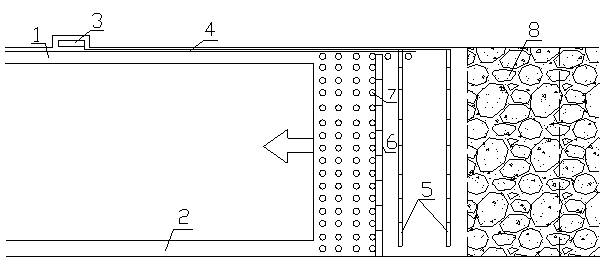

[0018] In the goaf filling method of steeply inclined coal seams of the present invention, firstly, a high-water quick-setting material grouting pump 3 and a belt conveyor 4 for transporting gangue are arranged in the upward trough 1 of the steeply inclined coal seam towards the longwall coal mining face; When the mining face advances 1.2-1.8m forward, along the inclination direction of the working face, on the top plate of the last row of pillars 7, interconnected grouting pipes 5 with a diameter of 1 inch and a length of 3m are successively laid out. Three groups of grouting holes are evenly arranged on the outer diameter of the pipe 5, and each group has four grouting holes, which are arranged symmetrically along the circumferential direction of the grouting pipe. The last row of pillars 7 of the entire mining face outside the tank 1 is arranged successi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com