Injection-extraction integrated sand prevention oil-well pump

An oil well pump and sand control technology, which is applied in the field of oil well pumps, can solve the problems of missing oil production period, pumping well fluid, and oil layer pollution, etc., and achieves the effect of reducing the workload of downhole operations and preventing sand sticking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

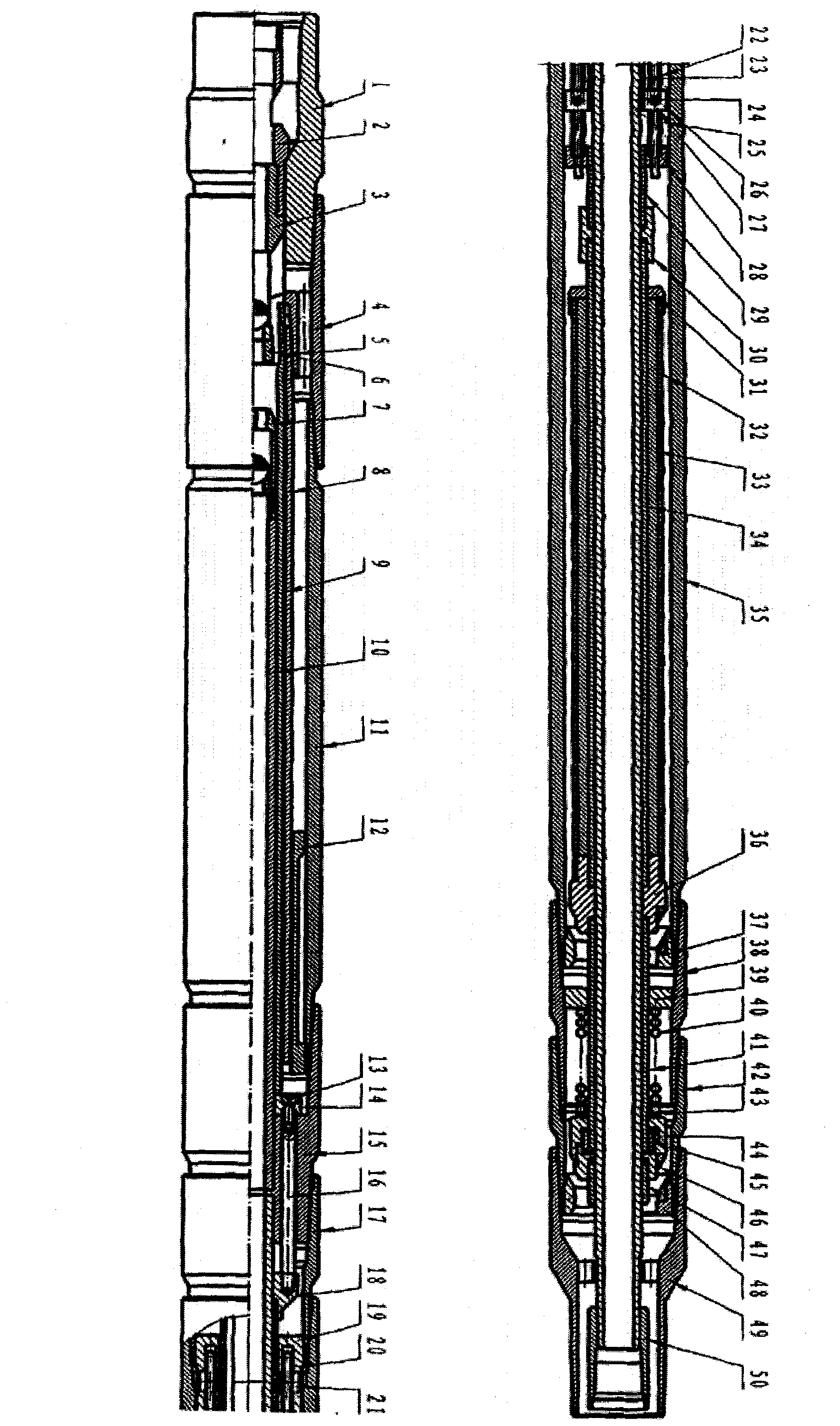

[0008] Such as figure 1 As shown, an injection-production integrated sand control oil well pump is composed of an upper joint 1, a hollow rod short-connected 2, a floating valve cover 3, a collar I4, a coupling I inner joint 5, a floating valve cover 6, Plunger cover 7, pump barrel sheath 8, pump barrel 9, plunger 10, jacket 11, touch pump cap 12, hexagon socket screw 13, connecting rod joint 14, joint I15, connecting rod 16, joint II17, touch Pump short joint 18, pulley seat 19, pulley 20, pulley shaft 21, steel wire rope I22, pump bump nipple 23, inner tube 24, steel wire rope II25, pump bump nipple lower joint 26, screw 27, wire rope sleeve joint 28, joint short Section 29, coupling II30, end cover 31, protective cover 32, heavy metal 33, valve connecting rod ball 34, nipple 35, ball valve 36, upper valve ball seat 37, joint III38, valve spring seat 39, valve spring 40, Valve connecting rod 41, joint IV42, valve spring seat 43, lower valve ball valve 44, valve connecting r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com