LED (light emitting diode) lighting module and method for manufacturing LED lighting module

A light-emitting module and manufacturing method technology, applied in the direction of semiconductor devices, light sources, electric light sources, etc. of light-emitting elements, can solve the problems of thickness increase, light decay, discoloration, etc., and achieve the effect of good heat dissipation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] In order to facilitate those of ordinary skill in the art to understand and realize the present invention, the present invention will be described in detail below in conjunction with the accompanying drawings and embodiments:

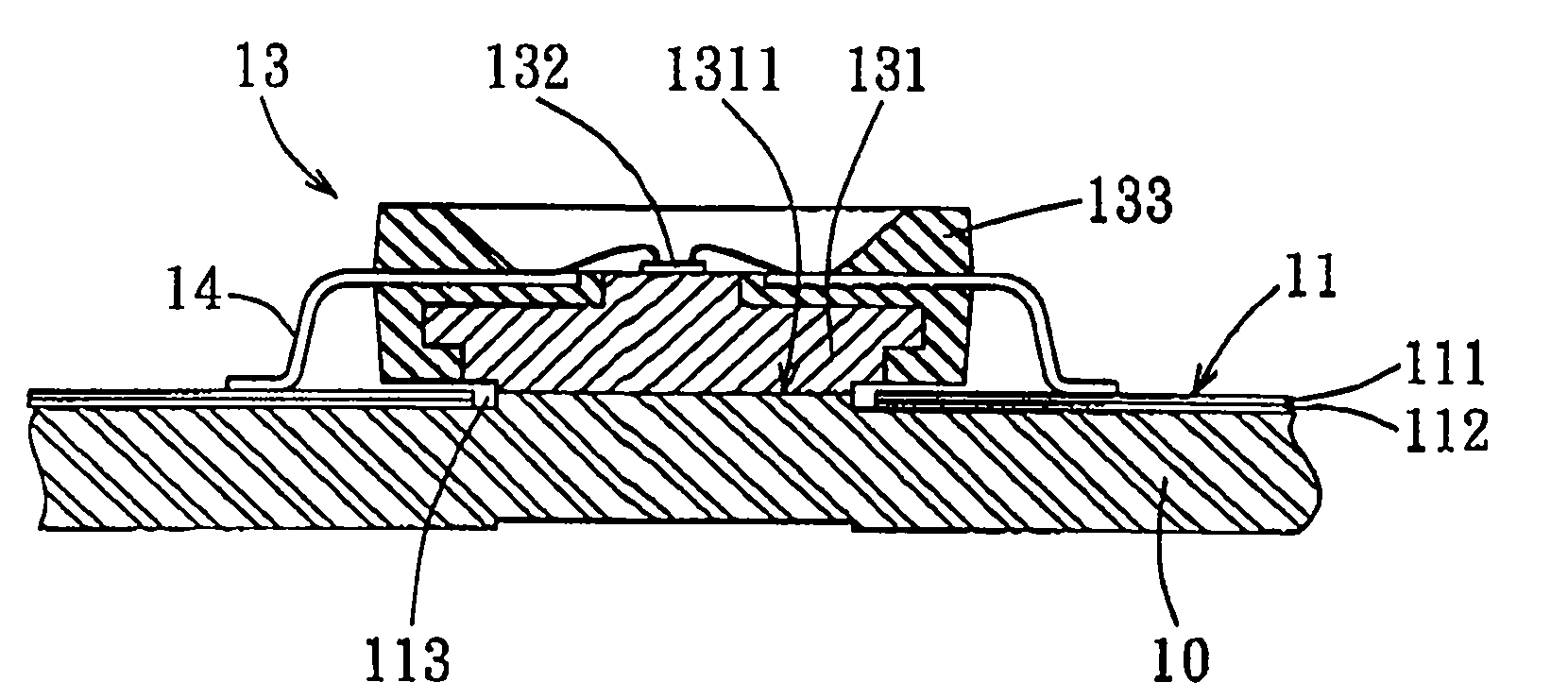

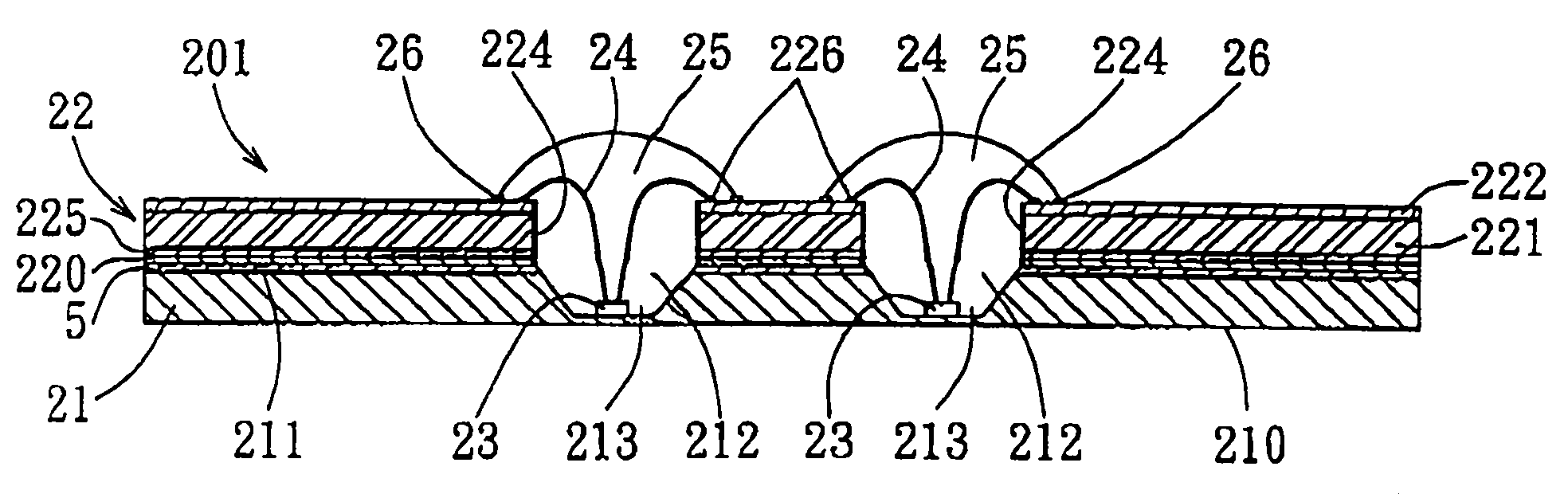

[0052] refer to image 3 , which is the first preferred embodiment of the LED light emitting module of the present invention, the LED light emitting module 201 includes a metal heat conducting plate 21, a circuit board 22, a plurality of LED crystal grains 23, a plurality of packaging colloids 25 and a thermal bonding of a metal material Layer 5, the circuit board 22 and the metal heat conduction plate 21 are bonded up and down through the thermal bonding layer 5, and the LED die 23 is disposed on the metal heat conduction plate 21 and exposed to the circuit board 22, and the LED die 23 is electrically connected to the circuit board 22.

[0053] refer to image 3 , Figure 6 , in more detail, the metal heat conducting plate 21 includes a bottom...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com