Optical frequency metering and testing device for laser vibration measurer

A technology of laser vibrometer and measurement test, which is applied in the direction of measuring device, ultrasonic/sonic wave/infrasonic wave, instrument, etc. It can solve the problem that the laser vibrometer cannot be measured and verified, and achieve a wide range of speed signals and ensure accuracy. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

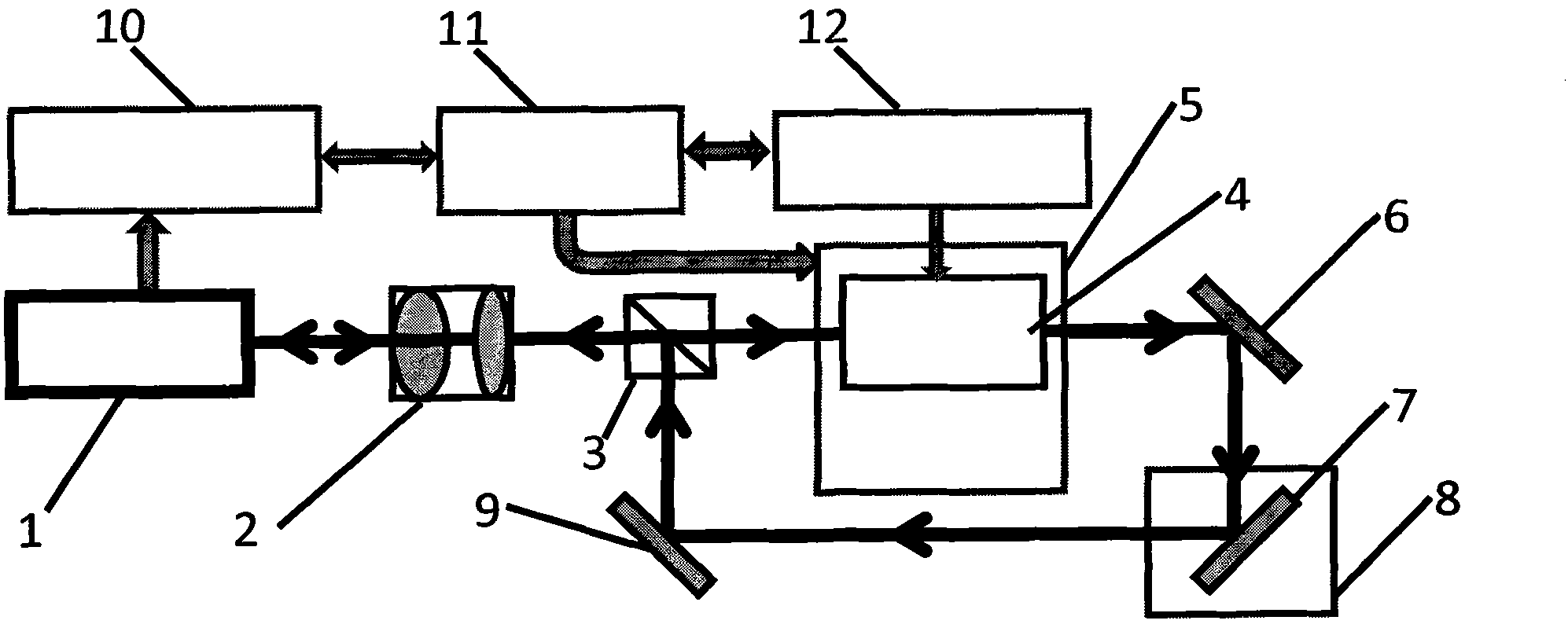

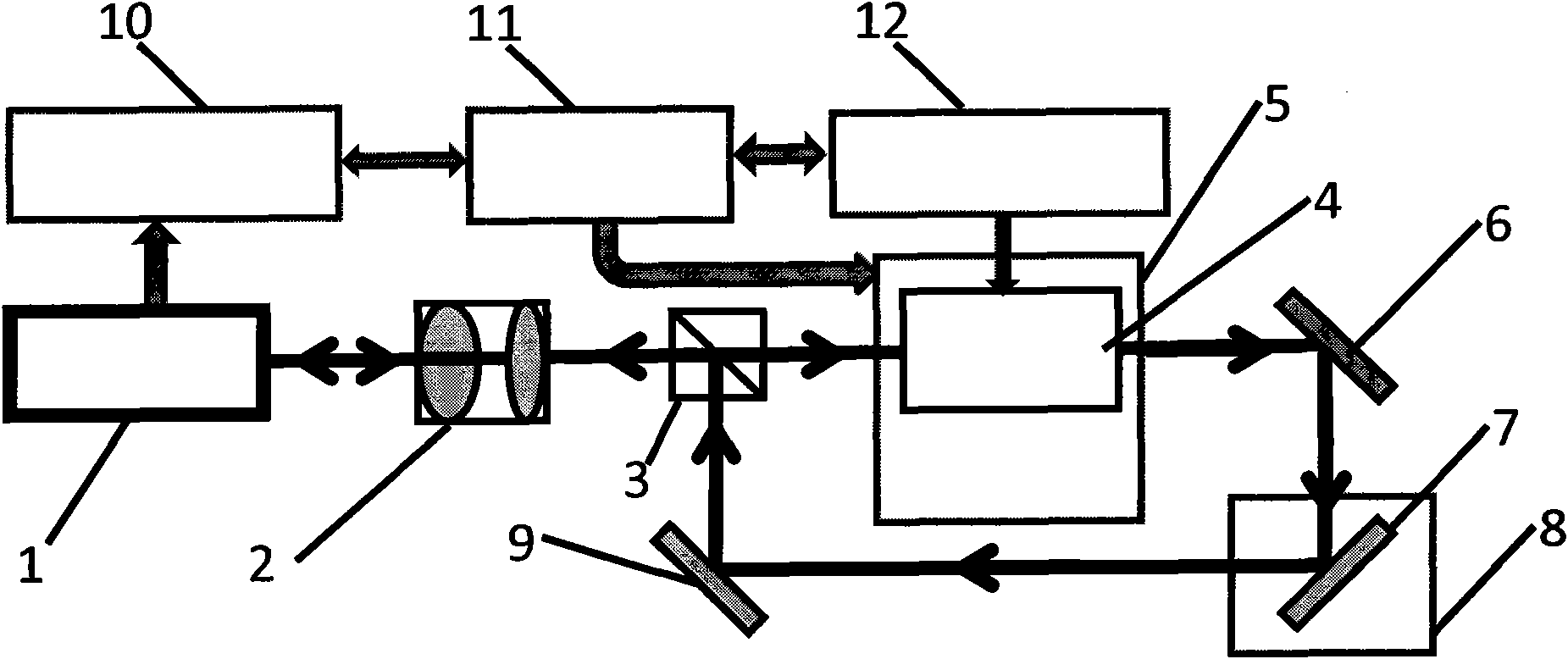

[0021] An optical frequency measuring and testing device for a laser vibrometer, such as figure 1 As shown in , its peripheral equipment is the laser vibrometer to be tested, which is composed of an optical frequency modulator, a signal generating device, an optical component, a precision attitude adjustment mechanism, a control system and a data acquisition system;

[0022] The optical components are responsible for the necessary light splitting, collimation and convergence of optical frequency modulation, including measuring beam adapter, beam splitter, plane mirror 1, plane mirror 2, plane mirror 3 and angle adjuster;

[0023] The laser light emitted by the laser vibrometer enters the optical frequency modulator after passing through the measuring beam adapter and the beam splitter. The optical frequency modulator realizes the frequency modulation of the measuring light of the laser vibrometer. , the plane reflector 2 and the plane reflector 3 return to the beam splitter, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com