Piston ring radial pressure detection device and detection method thereof

A technology of radial pressure and detection device, used in measurement devices, force/torque/work measuring instruments, instruments, etc., can solve the problems of pressure in and out, lengthened design cycle, backwardness, etc., and achieve the effect of accurate detection structure and simple steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention is described in detail below by preferred embodiments of the present invention:

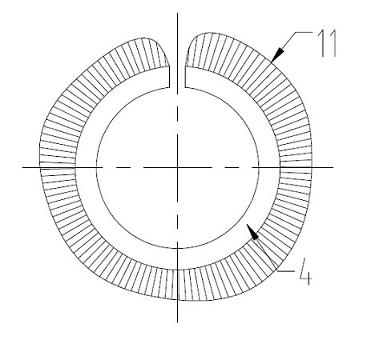

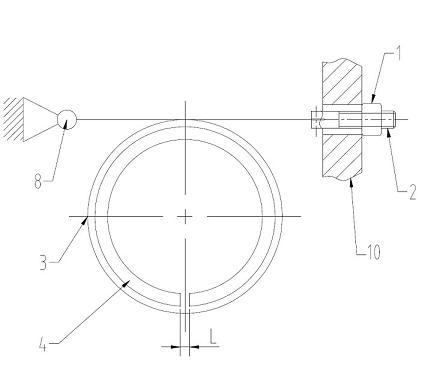

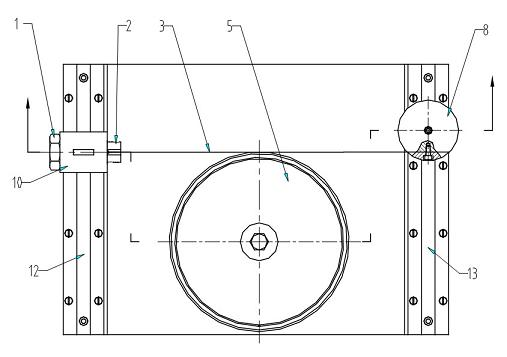

[0035] Such as figure 1 Shown is the pressure distribution diagram of each point of the piston ring after receiving pressure compression, figure 1 The length of the radial line segment outside each point of the outer circle of the middle piston ring 4 represents the pressure value 11 of each point, and the pressure distribution of each point of the piston ring 4 is obtained by connecting the ends of these radial line segments. When the piston is loaded into the cylinder, it is compressed and elastically deformed. However, the radii of each point on the outer circle of the piston ring 4 are different, such as figure 1 As shown, the pressure value 11 produced by each point on the cylinder is also different. Since the pressure value 11 of each point is determined by the radius of the point, the pressure detection device of the present invention provides accurate basic ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com