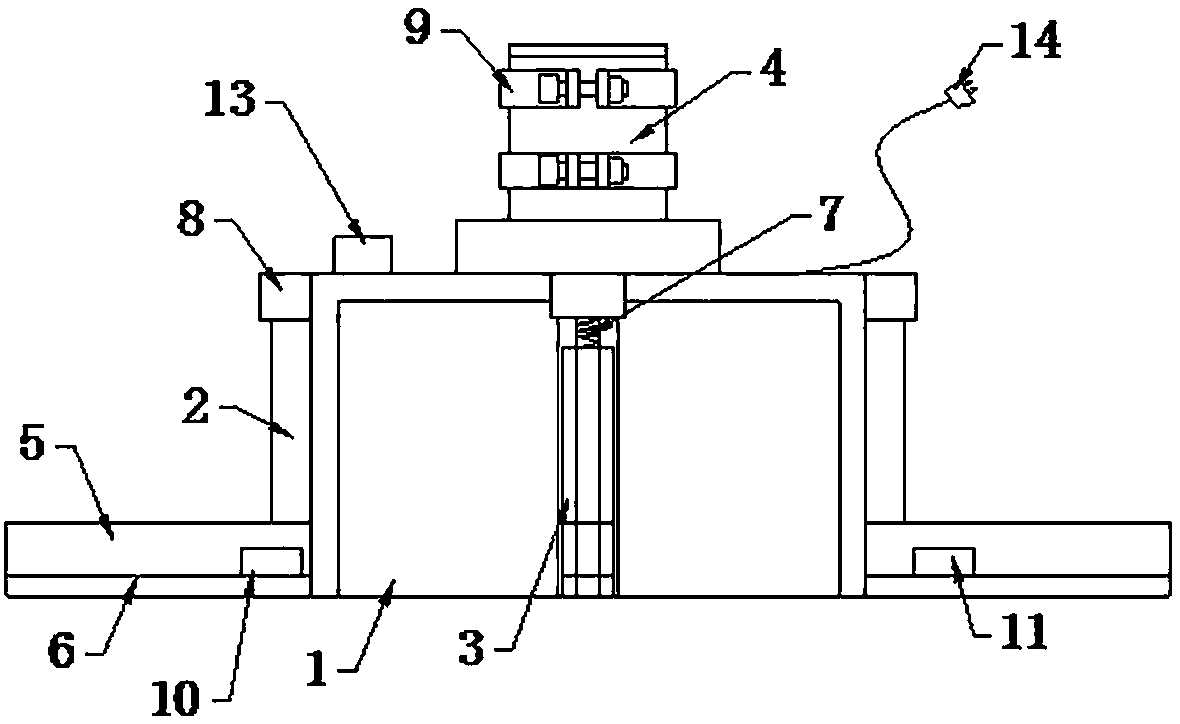

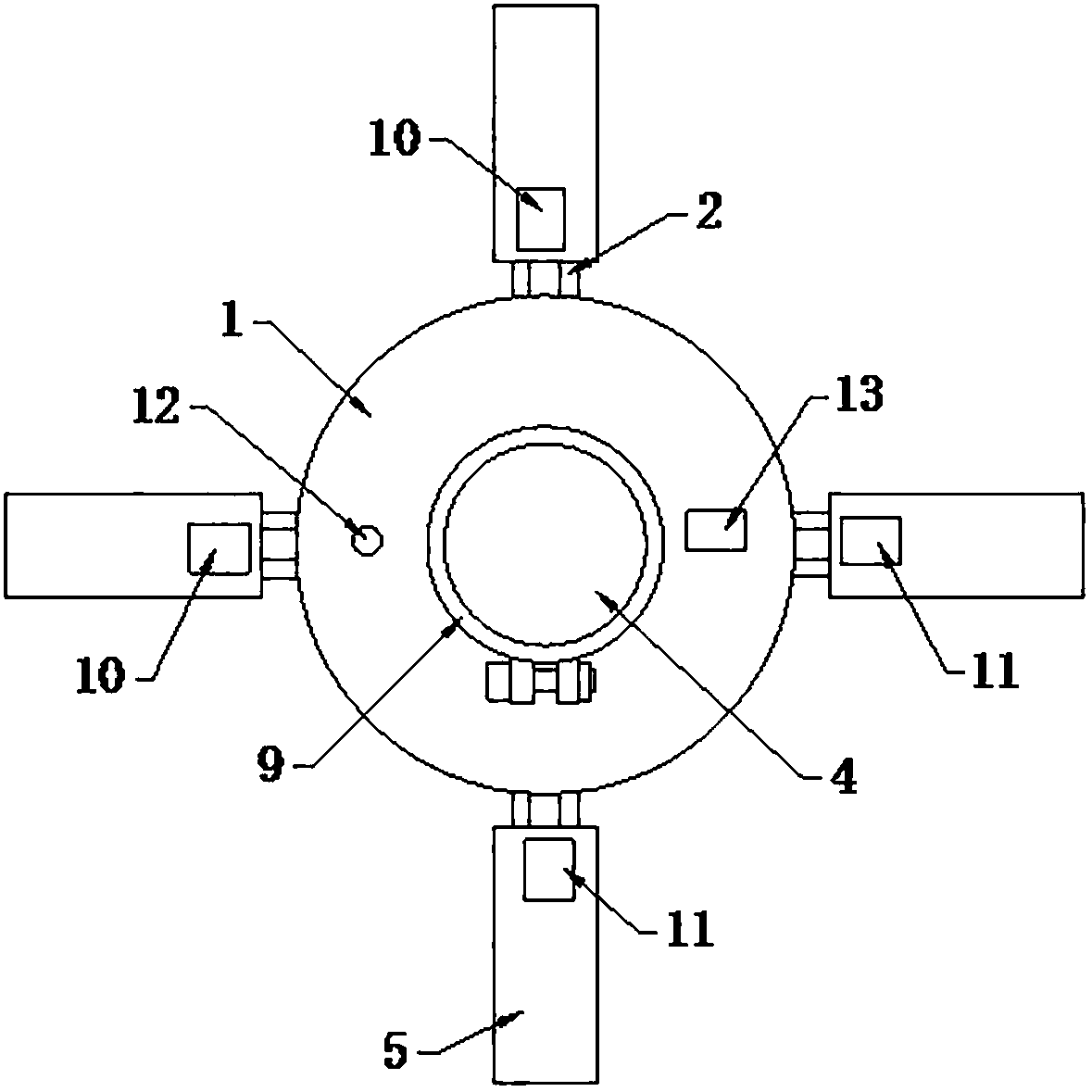

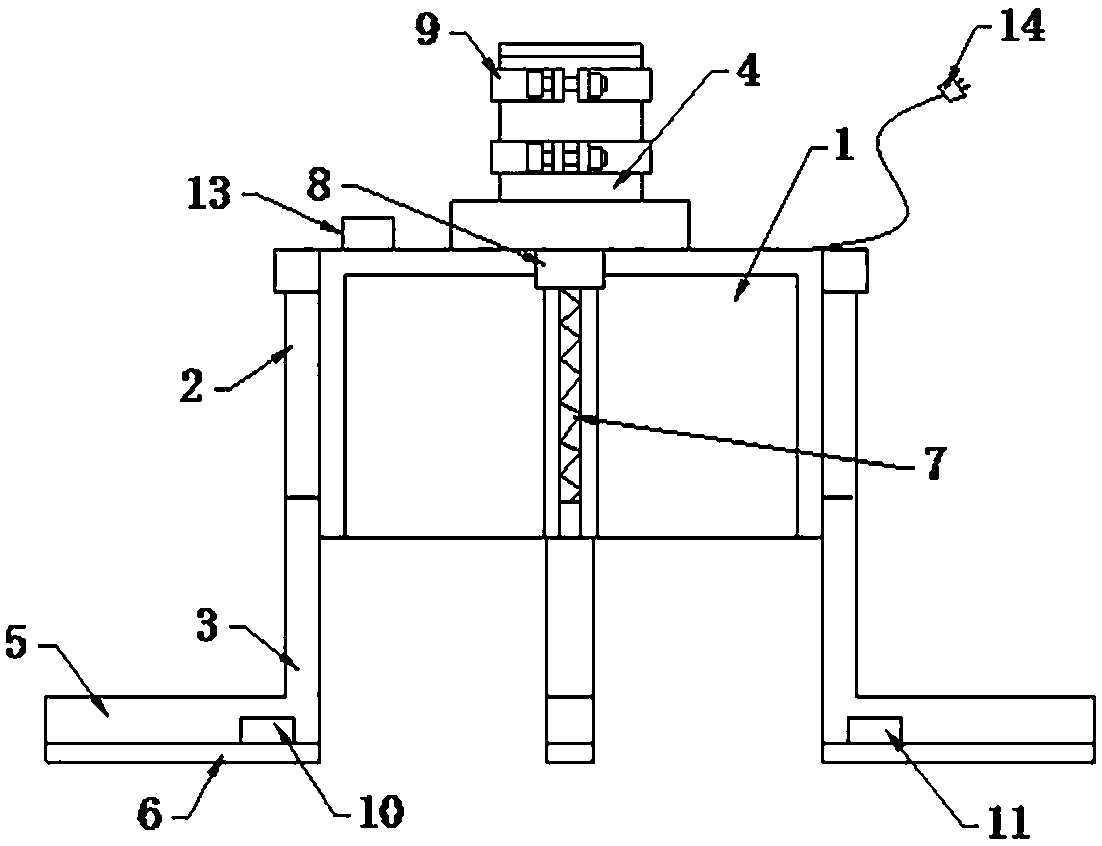

Core-drilling sampling auxiliary device for exterior wall thickness detection

A thickness detection and auxiliary device technology, applied in the sampling device and other directions, can solve the problems of the drilling rig tilting, the inability to drill through the wall, the environmental impact of the staff, etc., to achieve accurate detection structure, good automatic correction effect, corrosion resistance and mechanical properties. Excellent performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

experiment example

[0053] Experimental objects: use ordinary commercially available springs as the control group 1, use imported springs as the control group 2, and use the springs of this application as the experimental group.

[0054] Experimental requirements: The shape, thickness, and size of the three sets of springs are all the same, and the corrosion resistance test and the ball pressure test are carried out respectively, and the following data are obtained.

[0055] The specific results are shown in the table below:

[0056]

[0057] Combining the above table, comparing the data obtained by three different experimental objects under three different experimental methods, the corrosion resistance and mechanical properties of the spring of the present invention are better than those of the two control groups.

[0058] Compared with prior art, the beneficial effect of the present invention is:

[0059] 1. The present invention installs the auxiliary device on the existing drilling rig, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com