Vibration table fixture capable of accurately adjusting center of gravity

A vibrating table and fixture technology, used in vibration testing, machine/structural component testing, measuring devices, etc., can solve problems such as the inability to guarantee large specimens and fixtures, the damage of the moving ring of the electric vibrating table, and the fatigue failure of the sealing ring. , to achieve the effect of small difference in vibration value, less installation time, and improved efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in detail below in conjunction with the accompanying drawings.

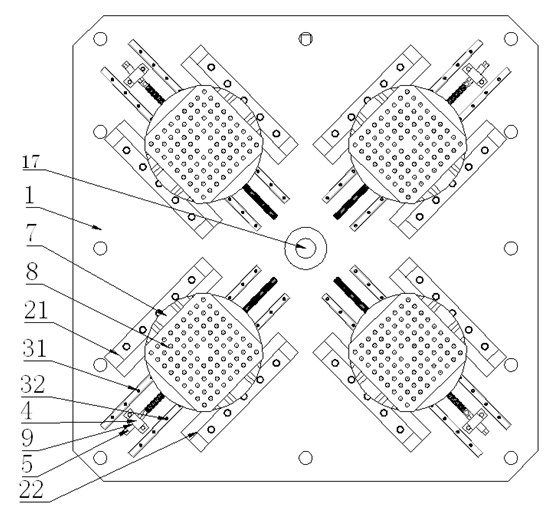

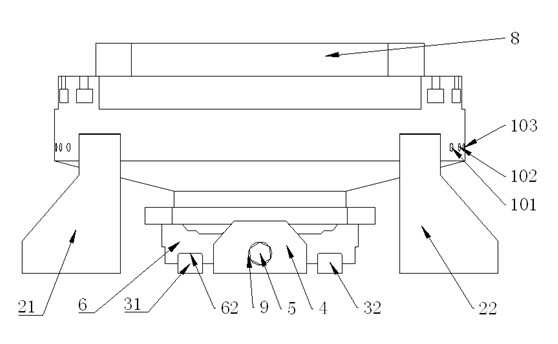

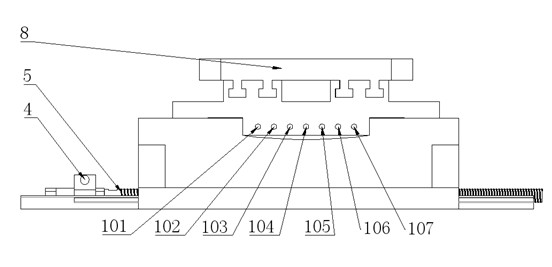

[0019] Such as Figures 1 to 7 As shown, the vibrating table clamp that can be precisely adjusted in the present invention includes a vibrating table top 1 and four sub-clamps. Each sub-fixture contains two guide support plates 21, 22 parallel to each other. On the one hand, the guide support plates can play a guiding role; To resist the overturning moment, two sliding bars 31, 32 parallel to each other are arranged between the two guiding support plates 21, 22, and a supporting block 4 is arranged between the two sliding bars 31, 32, and the guiding supporting plates 21, 22 , the sliding bars 31, 32 and the support block 4 are fixedly connected to the vibrating table top 1 respectively. Each sub-fixture also includes leading screw 5, slide block 6, support plate 7 and base 8, and support block 4 is provided with through hole 41, and a bearing 9 is installed in thi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com