Semiconductor circuit assembly

A circuit layout and semiconductor technology, applied in the direction of semiconductor devices, circuits, conductive connections, etc., can solve the problems of not always ensuring the contact of the contact section, interference with electrical contact, heating, etc., and achieve the goal of not easy to interfere, simple cost, and high current-carrying capacity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

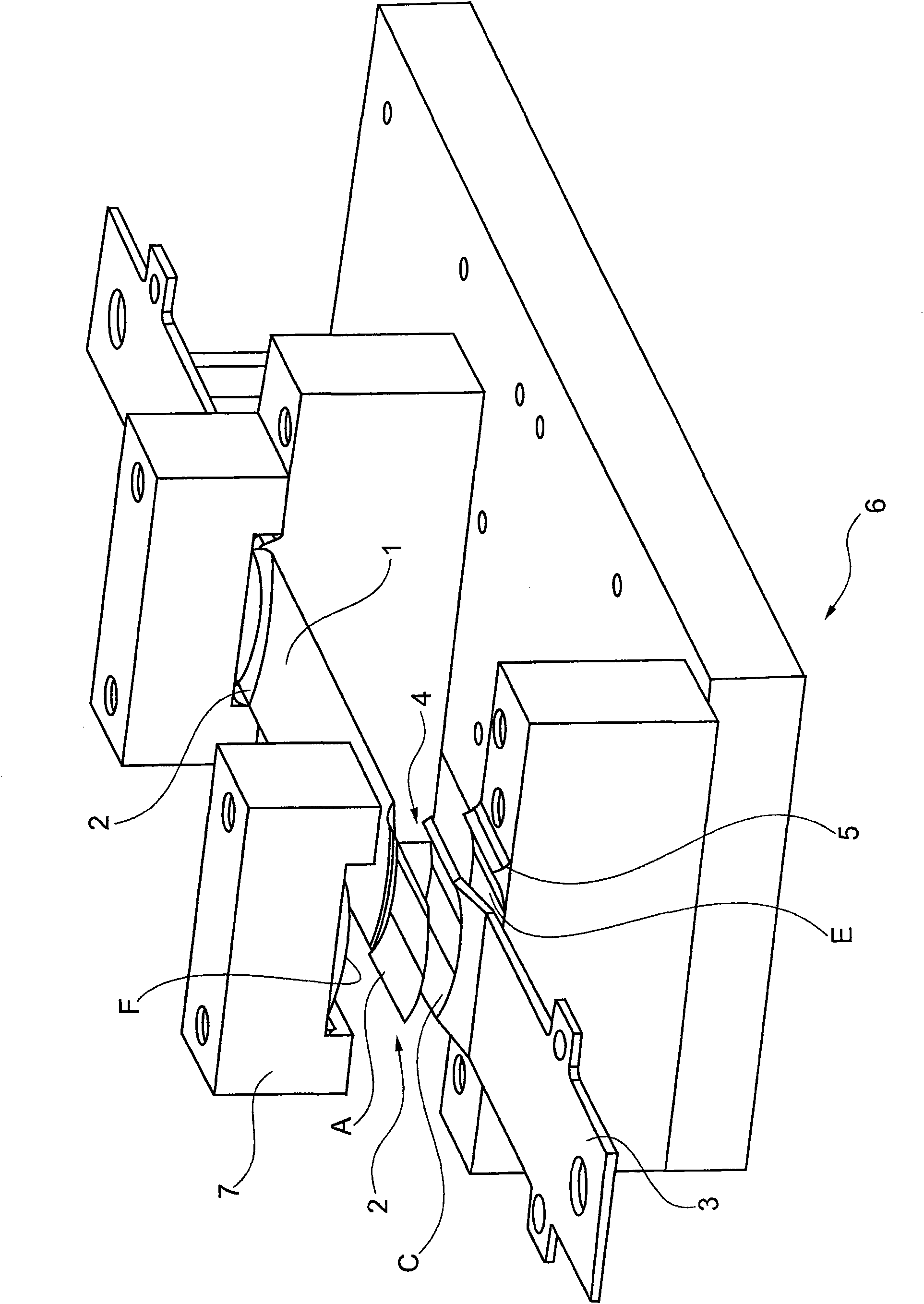

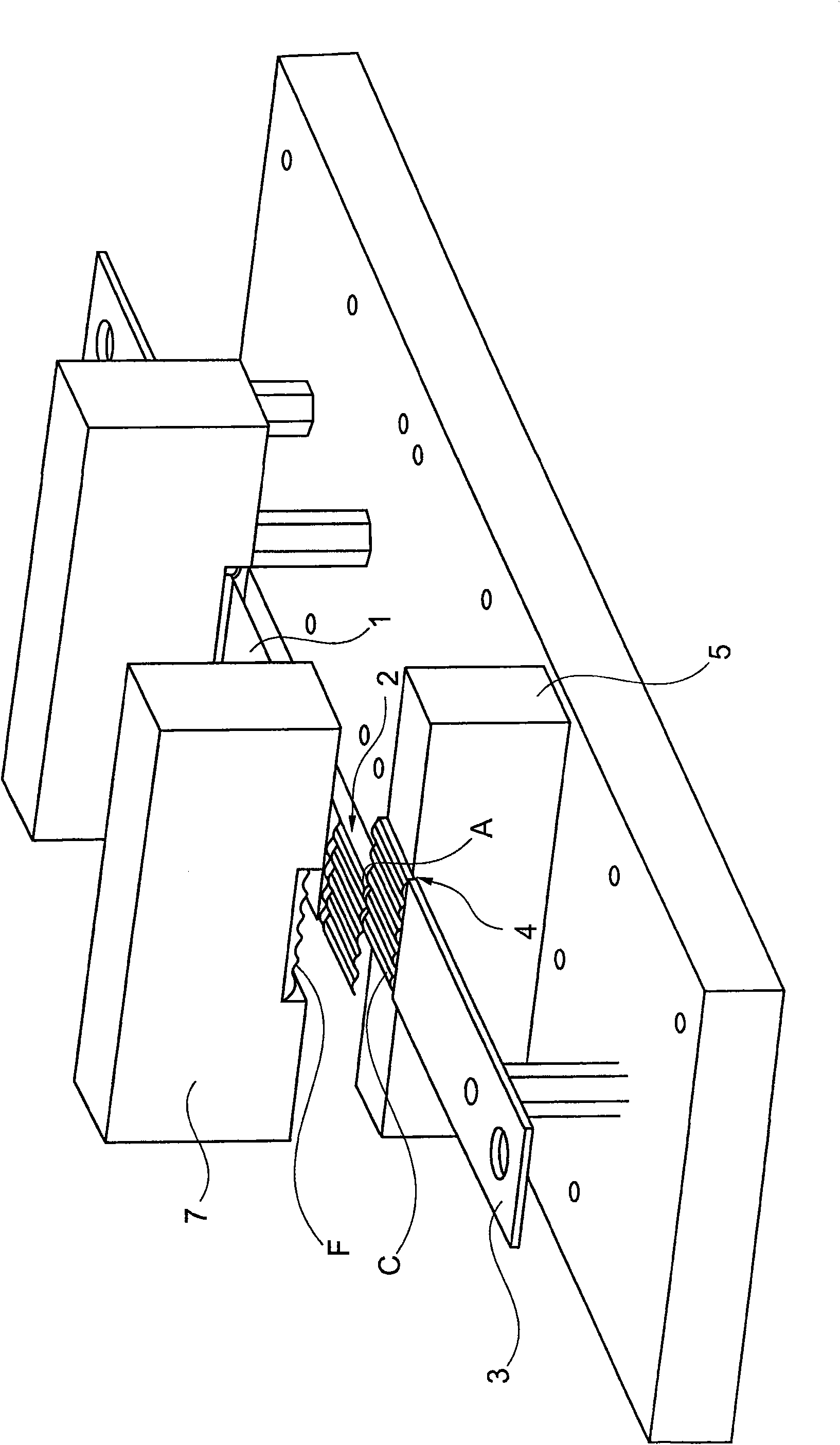

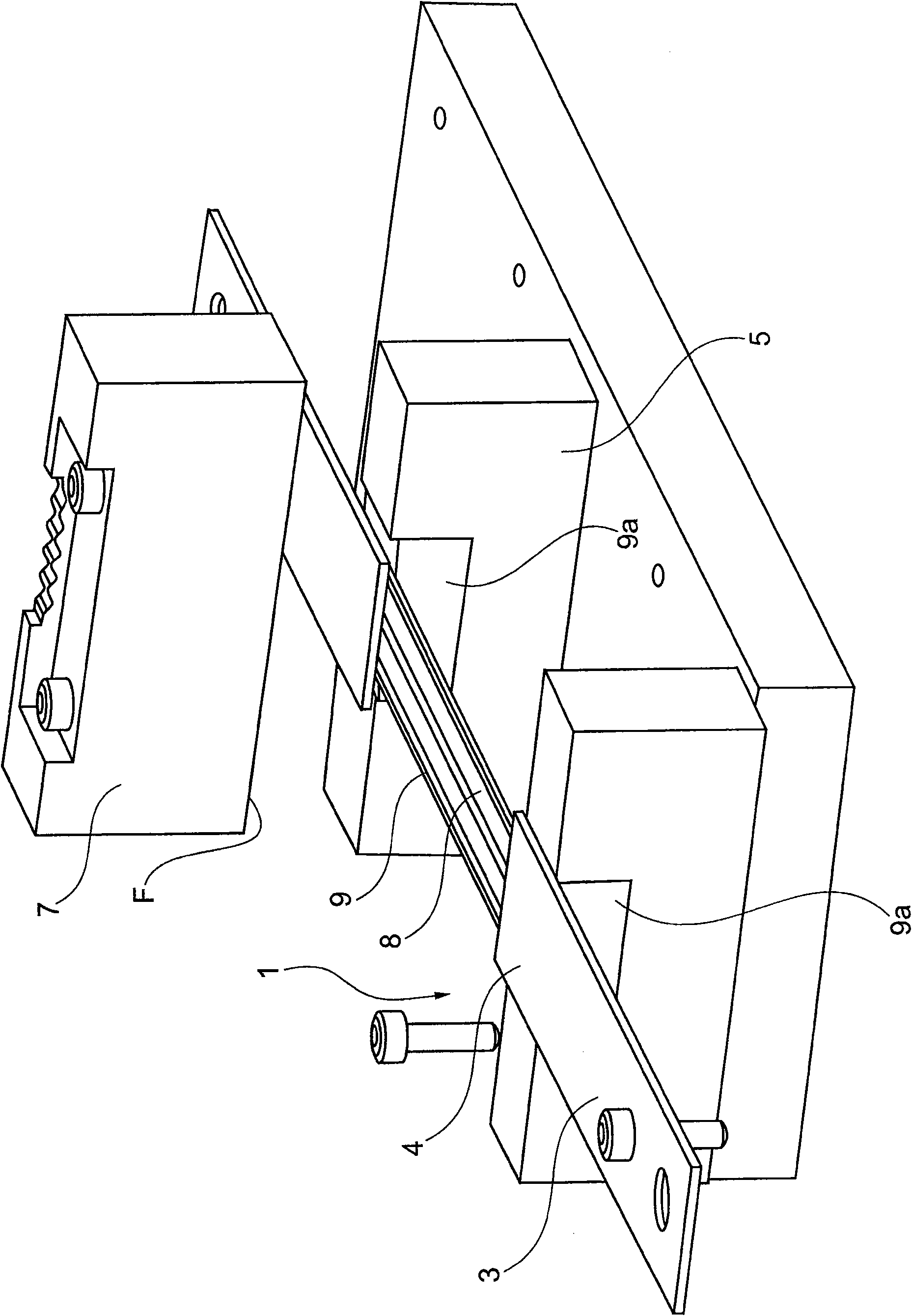

[0023] exist figure 1 In , the reference numeral 1 is used to designate the connecting device, which is formed from a film composite structure. The film composite comprises at least one electrically insulating film made of plastic, which has metallization on at least one side. The metallization can be configured, for example, in the form of conductor tracks. Of course, this metallization can be provided on both sides of the electrically insulating plastic film. The reference number 2 is used to designate the first contact section of the thin-film composite structure 1 . In the region of the first contact section, the metallization is exposed, but it can otherwise be covered by another layer of insulating plastic for insulation purposes. as from figure 1 As can be seen, the connecting device can also have two first contact sections 2 at its two ends. The first contact section 2 has a first contact surface A and an opposite (not visible here) second contact surface B. FIG. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com