Epitaxial growth method of W type antimonide class II quantum well

An epitaxial growth and quantum well technology, applied in the semiconductor field, can solve the problems of immature semiconductor optoelectronic devices and wide band gap.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

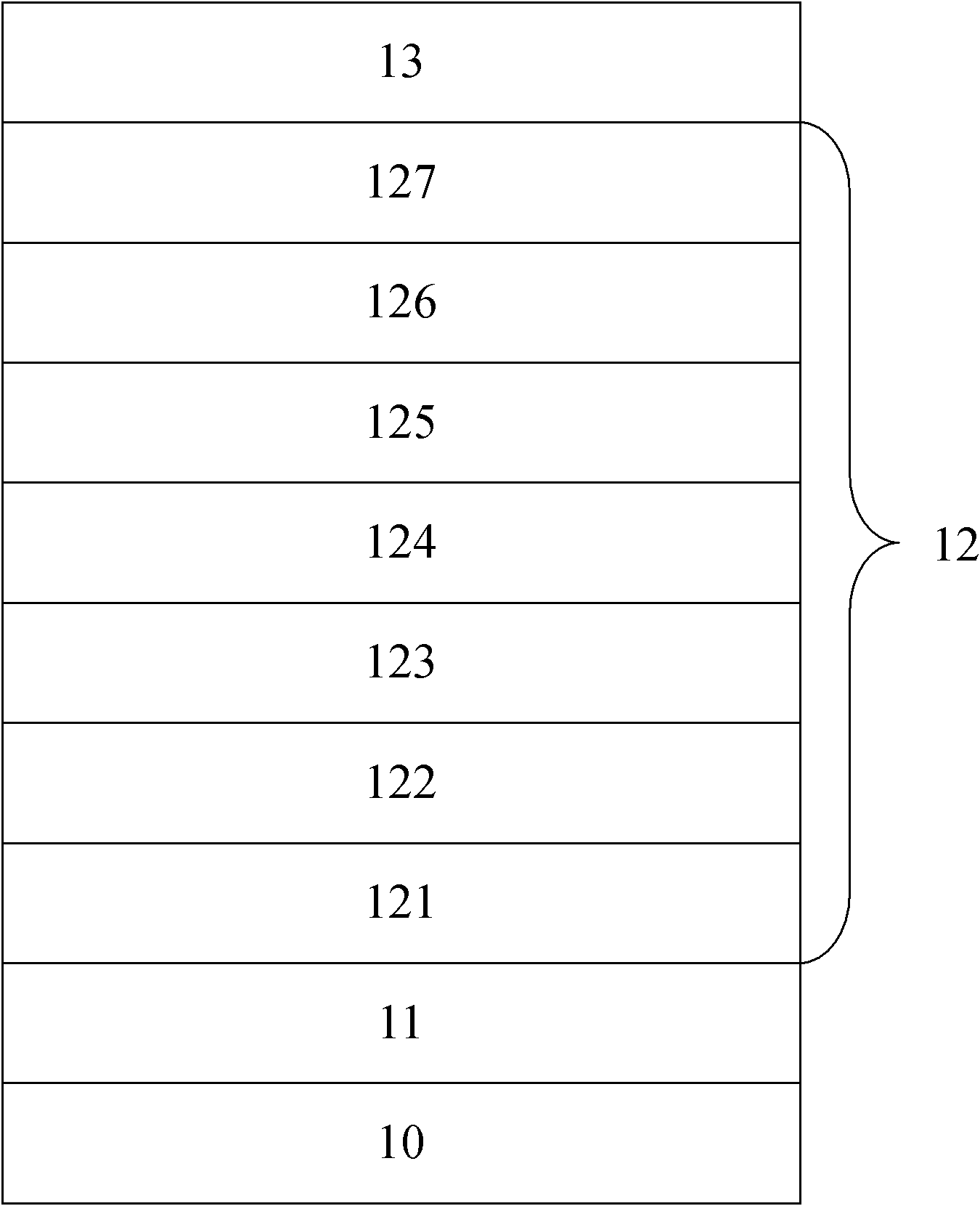

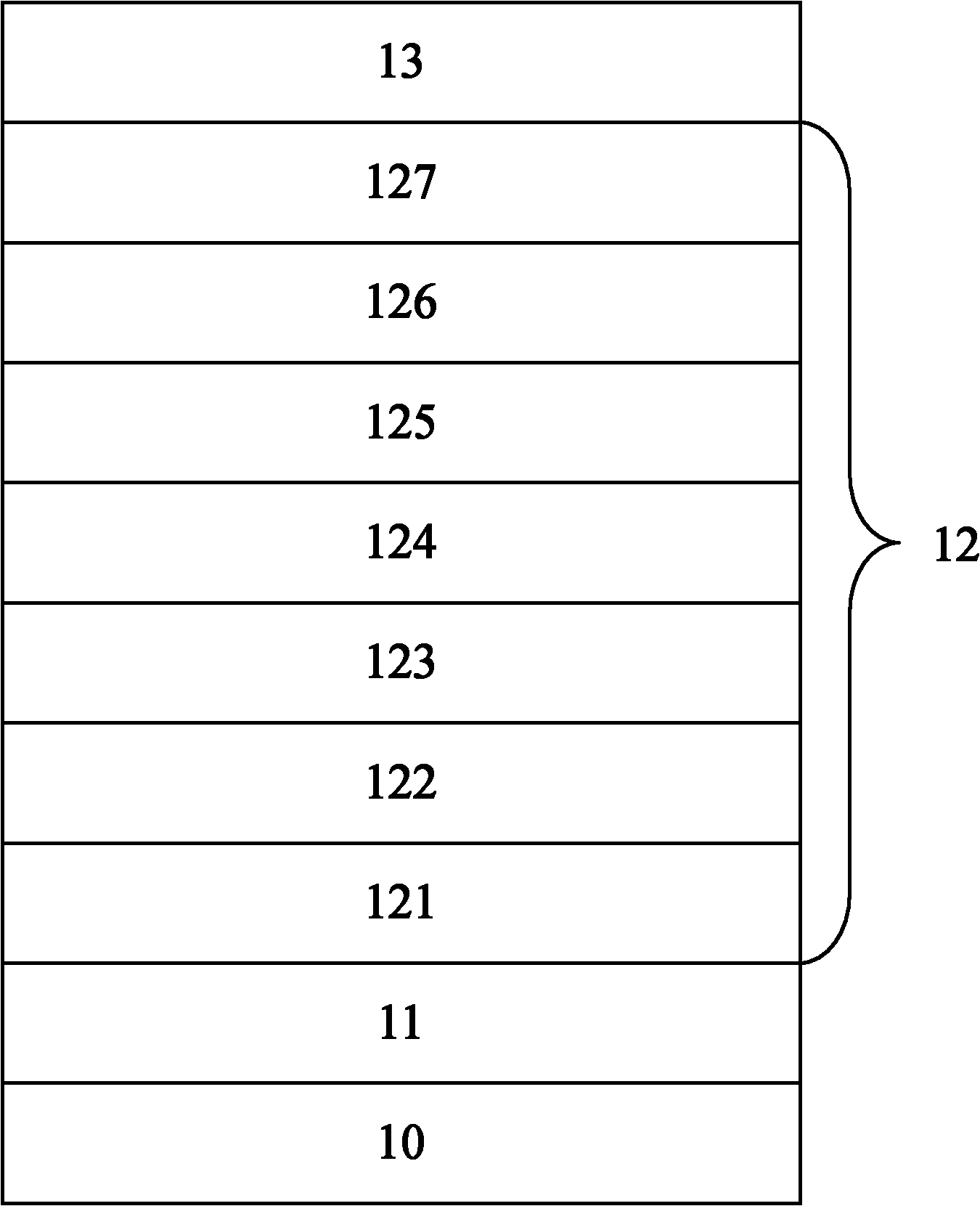

[0019] see figure 1 As shown, the present invention provides an epitaxial growth method of a "W" type antimonide type II quantum well, comprising the following steps:

[0020] Step 1: select a substrate 10, the substrate 10 is a GaSb (001) substrate;

[0021] Step 2: Deoxidize and degas the substrate 10 and observe the surface reconstruction, which means that the temperature of deoxidation is 630°C, then the temperature is raised to 660°C for degassing, and after 15 minutes, the temperature is lowered to 610°C, and GaSb is grown for 5 minutes. After cooling to 490°C, reconstitution was observed.

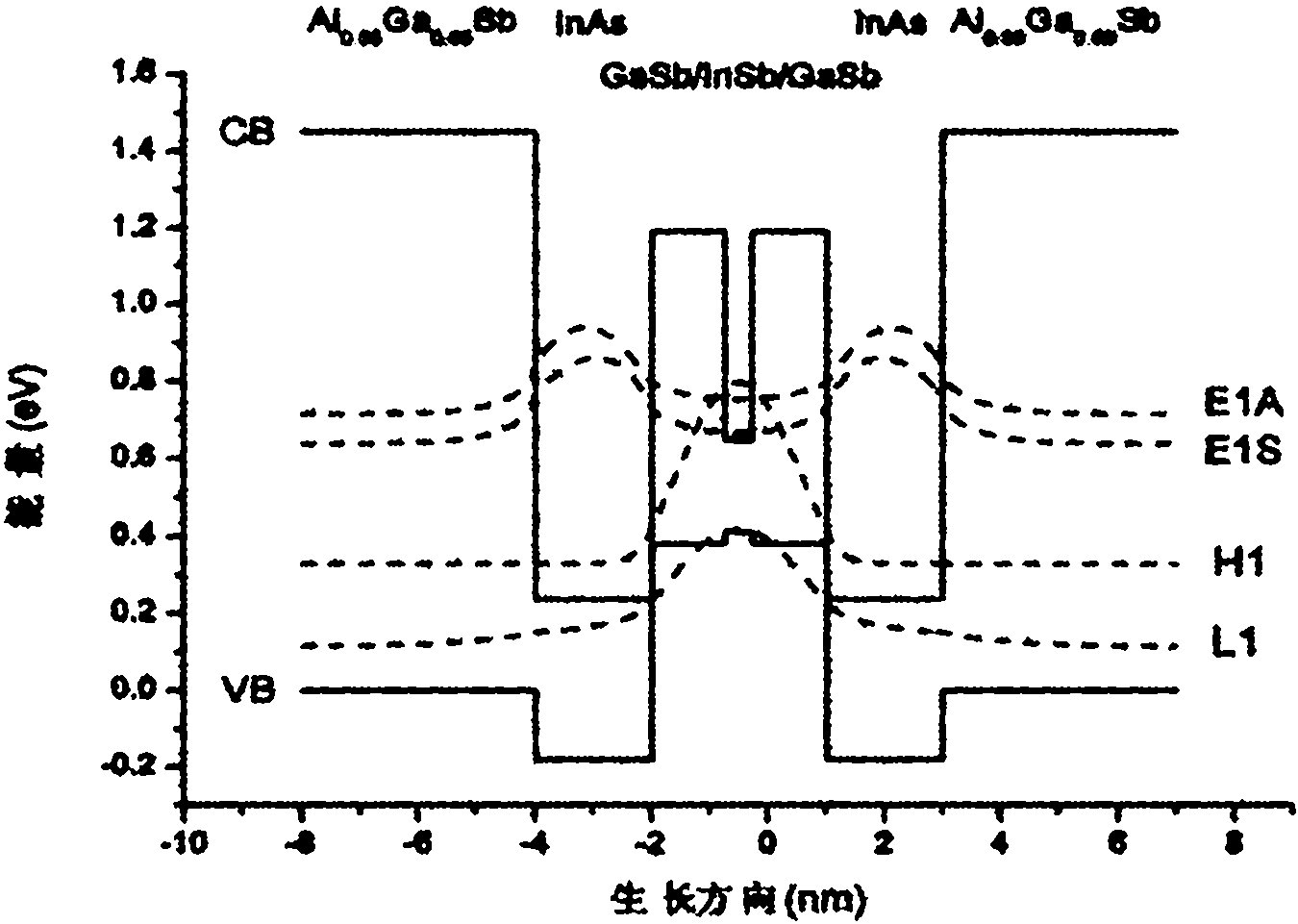

[0022] Step 3: A buffer layer 11, a 10-cycle “W” structure type II quantum well active region 12 and a GaSb cap layer 13 are sequentially grown on the substrate 10. The buffer layer 11 is made of GaSb, and the 10 Each period of the "W" structure type II quantum well active region 12 includes: an Al 0.35 Ga 0.65 Sb barrier layer 121, growth time 16s, thickness 4nm, this layer and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com