Full-automatic processing method and device for tasteful tea

A processing device and processing method technology, applied in the field of fully automatic tea processing methods and devices, can solve the problems of large influence of human factors, low efficiency, scattered processing procedures and other problems of operating technicians, so as to improve product quality and stability, Avoid the influence of human factors and the effect of simple device structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] Embodiment 1 of the present invention: full-automatic green tea processing method, first carry out green tea processing, utilize automatic control device to carry out linkage timely control to the finishing temperature, feed amount and drum rotating speed in the finishing process; The tea is automatically sent to the kneading process for kneading processing, and the automatic control device is used to control the kneading pressure and the speed of the kneading plate in a timely manner in the kneading process; the tea after the kneading process is automatically sent to the shaping and drying In the drying process, the automatic control device is used to control the temperature, humidity, shaping speed and frying hand speed in the shaping and drying process in a timely manner; the process parameters in the above processes all adopt mature process parameters.

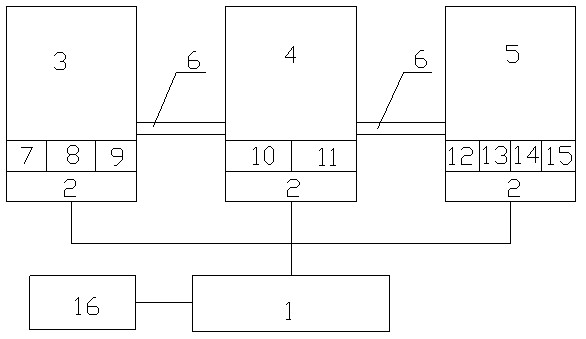

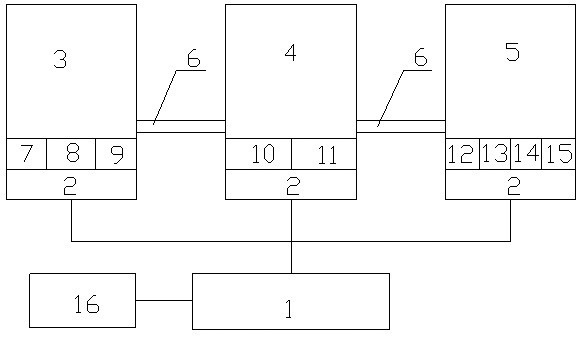

[0016] The structure of the automatic tea processing device is as follows: figure 1 As shown, it includes a maste...

Embodiment 2

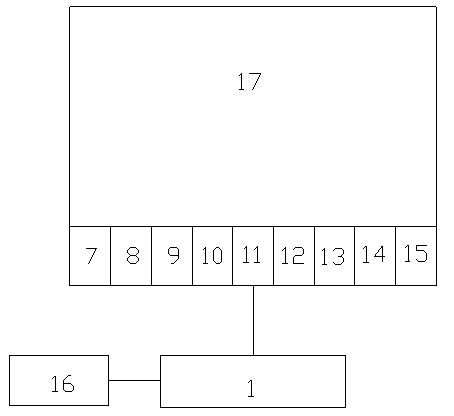

[0018] Embodiment 2 of the present invention: the structure of full-automatic tea processing device is as figure 2 As shown, it includes an automatic master control device 1, a visual operation panel 16 is connected to the automatic master control device 1, the automatic master control device 1 is connected with a tea processing container 17, and an adjustable electric heating module 7 is arranged in the tea processing container 17 , feed control module 8, rotational speed control module 9, kneading pressure adjustment module 10, kneading pan rotational speed adjustment module 11, temperature control module 12, humidity adjustment module 13, shaping speed adjustment adjustment 14 and frying hands speed adjustment module 15, they all Connect with the automatic master control device 1.

[0019] When adopting the device enumerated in embodiment 2, it is only necessary to control the respective control quantities of the three processes and the speed of the feed port and the disch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com