Plate shape closed-loop control method based on influencing self learning of matrix

A technology of influence matrix and closed-loop control, applied in the direction of contour control, etc., can solve the problems that the shape control method is difficult to apply in practice, it is difficult to achieve stable work, and the difficulty of intelligent methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

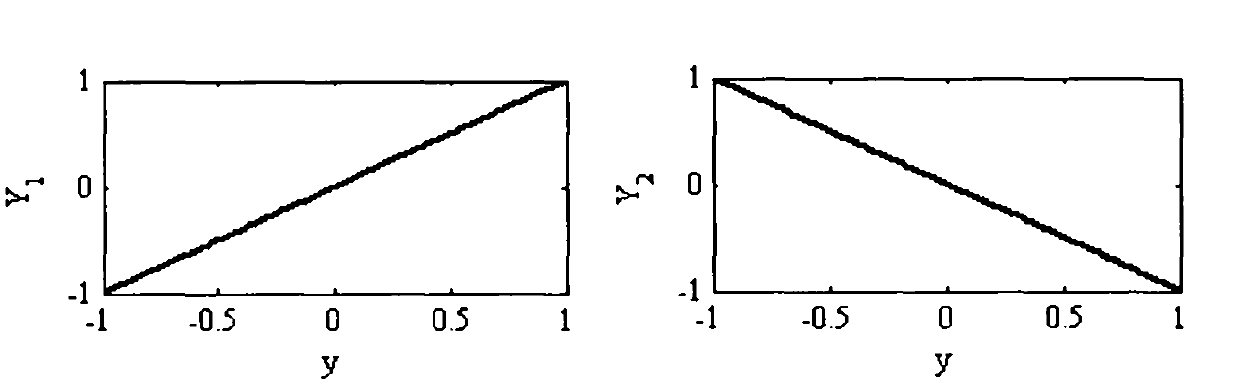

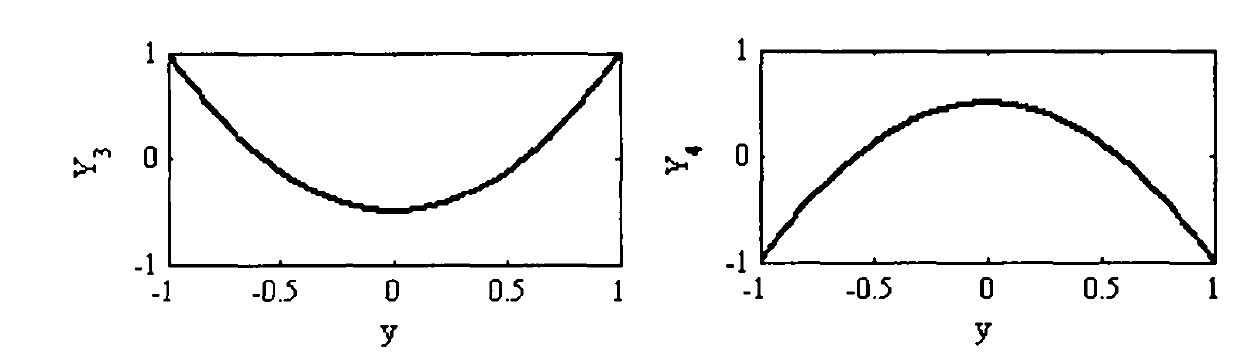

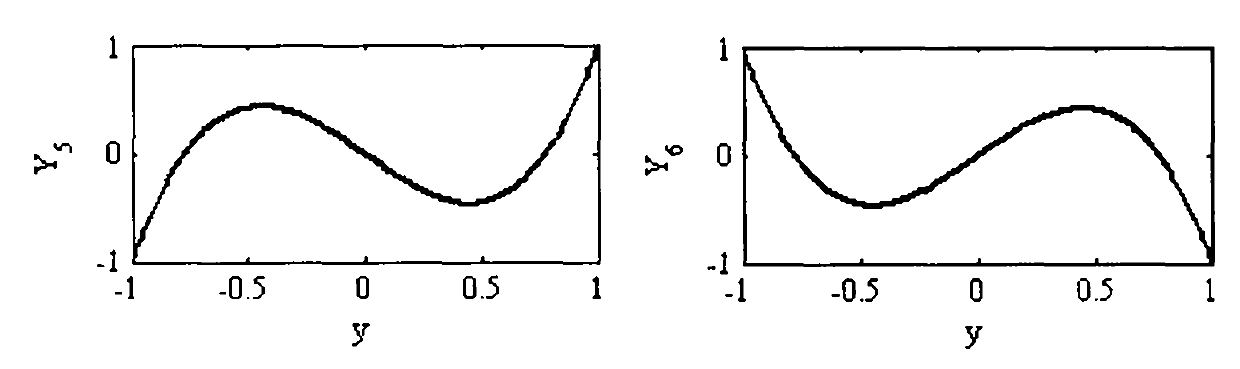

Image

Examples

Embodiment Construction

[0108] The specific implementation process of the present invention will be further described below with reference to the accompanying drawings and embodiments. During the rolling process, the work flow of the closed-loop control model of flatness based on the influence matrix self-learning is as follows: Figure 5 shown.

[0109] Taking a reversible strip cold rolling mill equipped with work roll bending, intermediate roll bending, roll inclination, segmental fine cooling and other flat shape control means as an example, it is explained that it is equipped with the flat shape closed-loop control system of the present invention. The specific implementation steps:

[0110] (1) In the present invention, the influence coefficients in the influence matrix include the influence coefficients of all the plate shape control mechanisms except the segmented fine cooling. Therefore, when determining the key influencing factors, the influence factors of the segmented fine cooling system ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com