Method and equipment for testing shading performance of coated glass, filmed glass or film-coating glass

A technology of testing equipment and coating film, which is applied in the direction of material thermal conductivity, etc., can solve problems such as lack of testing data, difficulty in acceptance by architects, and inability to measure secondary radiation, and achieve the effect of strong operability and comprehensive and intuitive data

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

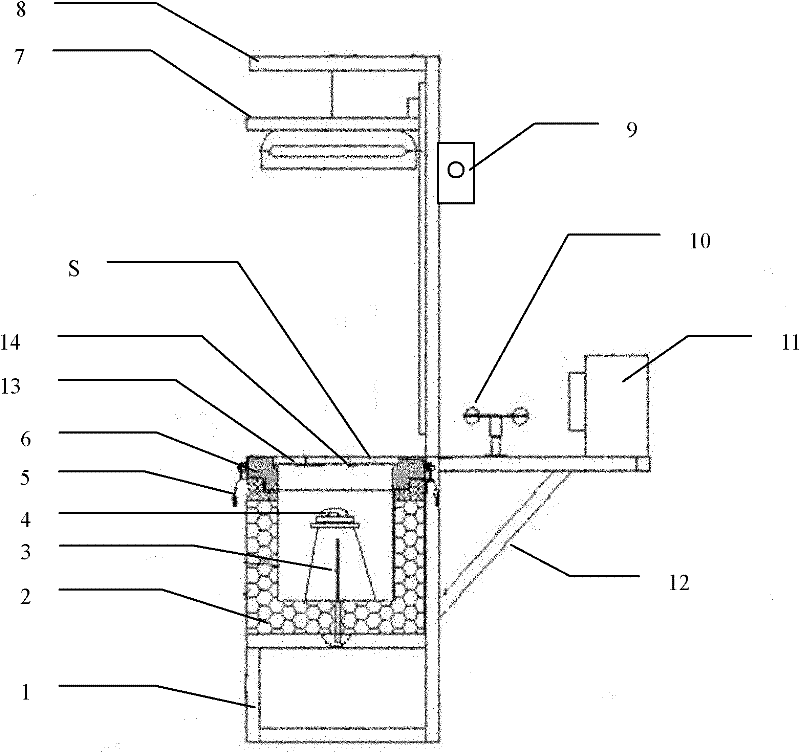

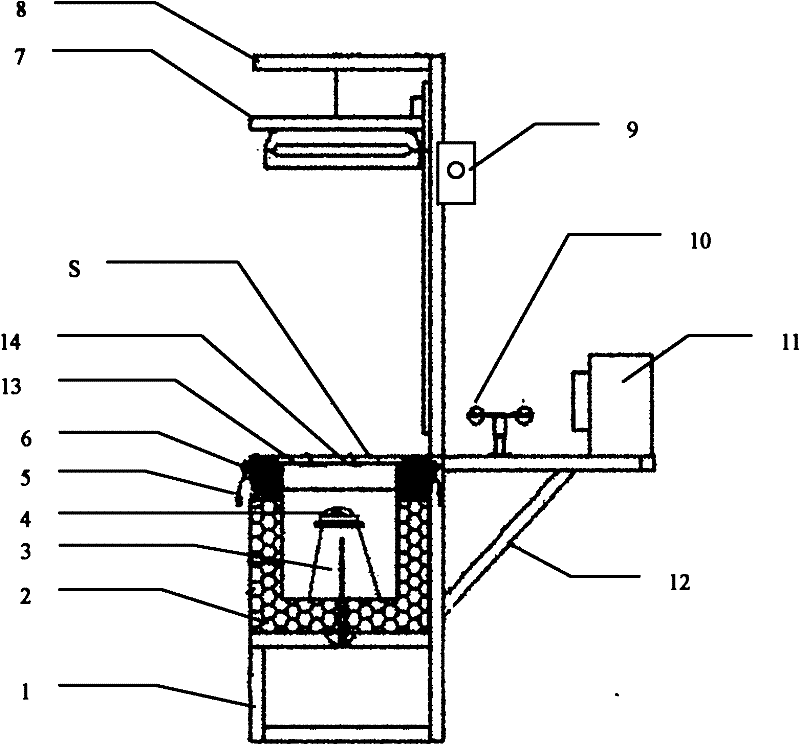

[0053] Embodiment 1: Evaluation of the sunshade performance of a coated glass

[0054] Specimen description: transparent coated glass, size 400mm×400mm×4.0mm.

[0055] Calibrate according to step 1, where the irradiation intensity is 900W / m 2 , the wind speed is 1m / s. When the air temperature in the metering box is measured at 26°C, the average heat flux q of the inner surface of the standard test piece SS ss 53.7W / m 2 , the radiation intensity R in the metering box ss 351.5W / m 2 , calculate the reference value E ss =405.2W / m 2 .

[0056] Test the specimen according to step 2, and the test conditions remain unchanged. When the air temperature in the metering box is measured at 26°C, the average heat flux q of the inner surface of the standard test piece SS s 28.4W / m 2 , the radiation intensity R in the metering box s 133.7W / m 2 , calculate E s =162.1W / m 2 .

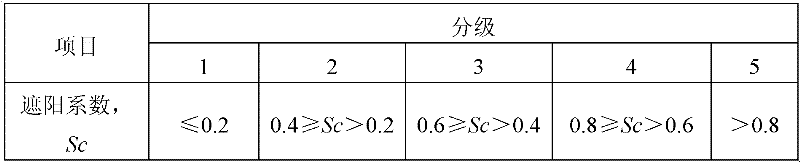

[0057] According to the formula (1), it is calculated that Sc=E s / E ss =0.40, according to Table 1, t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal conductivity | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com