Optical structure for improving output frequency of pulsed laser

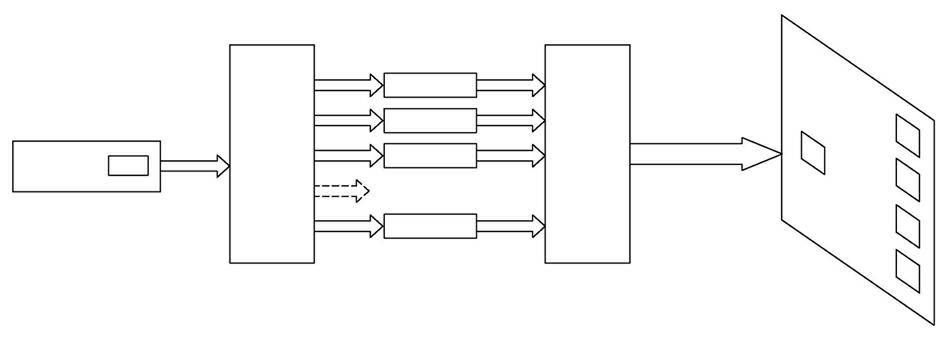

A pulse laser and output frequency technology, applied in the laser field, can solve the problems of reducing the average power of laser pulses and increasing device loss, and achieve the effect of reducing single pulse energy and increasing pulse frequency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with the drawings and specific embodiments.

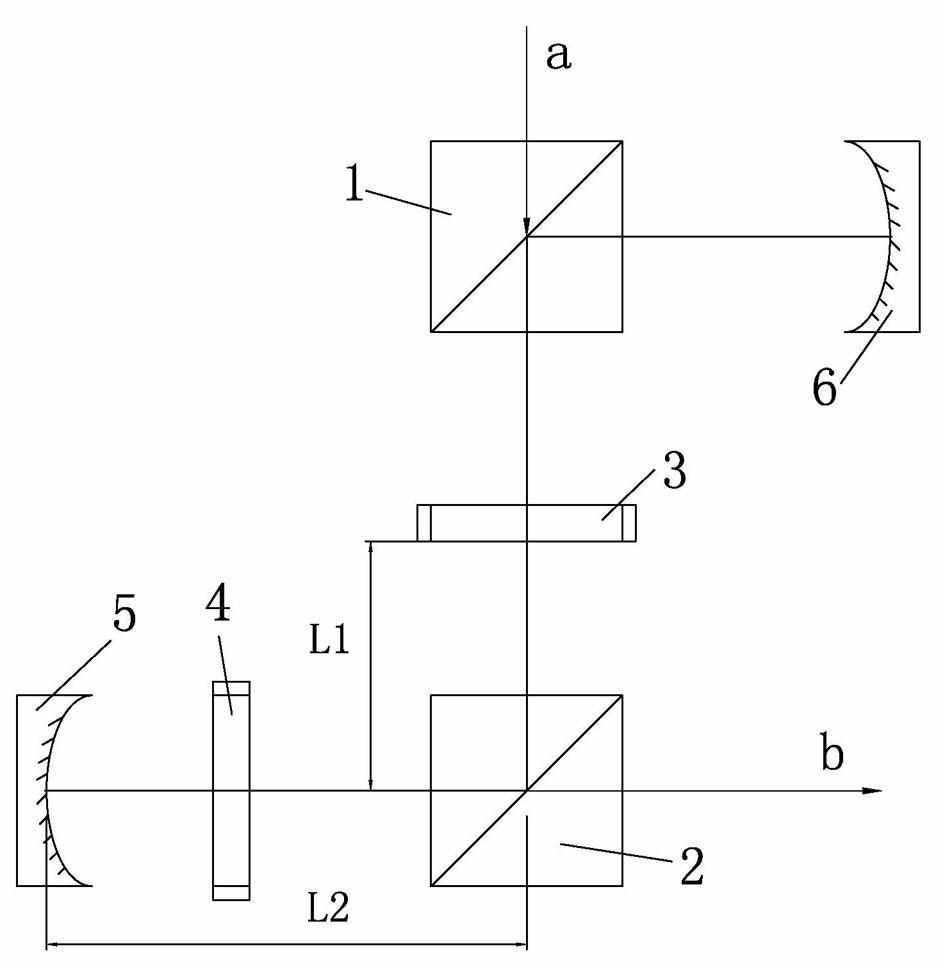

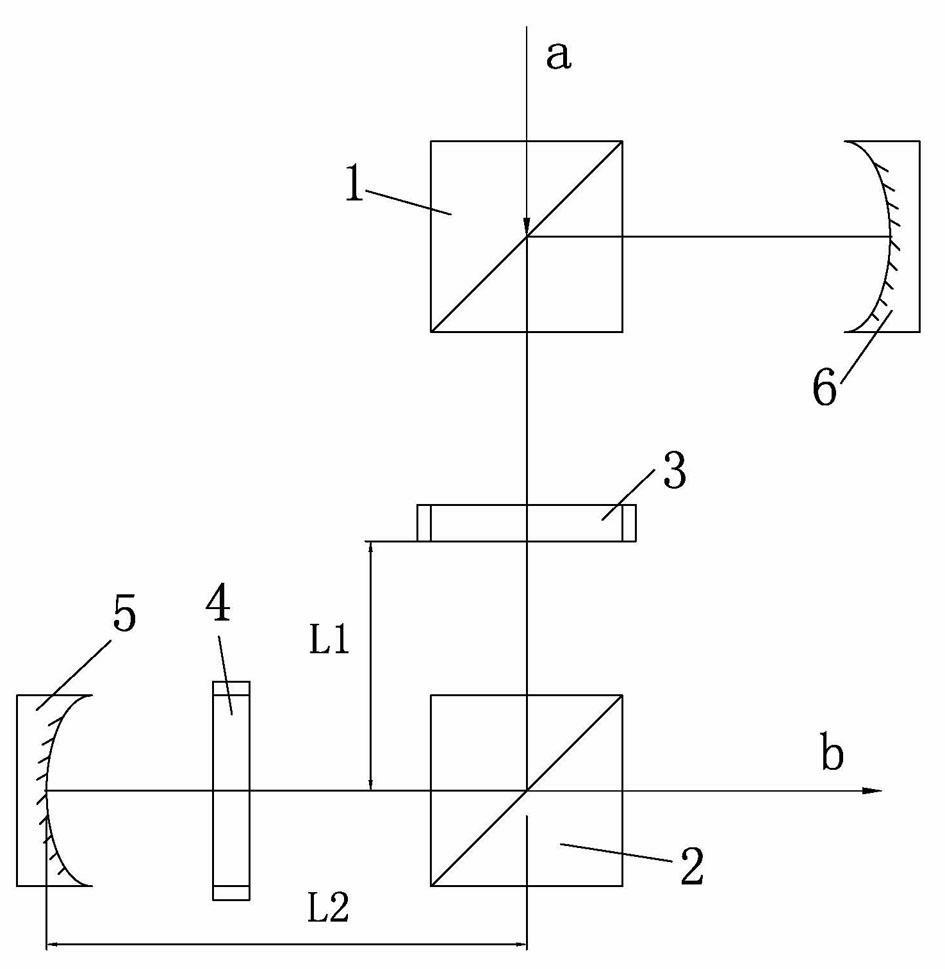

[0015] Such as figure 2 Shown is a specific embodiment of the present invention, an optical structure for increasing the output frequency of a pulsed laser, including two polarization beam splitting prisms (PBS): a first polarization beam splitting prism 1 and a second polarization beam splitting prism 2; two adjustable Wave plates: the first adjustable wave plate 3 and the second adjustable wave plate 4; two cavity mirrors: the first cavity mirror 5 and the second cavity mirror 6. The two tunable wave plates 3, 4 can be electro-optic crystals or magneto-optic crystals; the two cavity mirrors 5, 6 can be plano-concave cavity mirrors.

[0016] The working process is as follows. When the original pulsed laser a enters the optical structure through the first polarization beam splitter 1, the first tunable wave plate 3 is in the state of the λ / 2 wave plate, and wh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com