Laser rapid processing method of ring groove in inner cavity of corrugated horn antenna

A technology of corrugated horns and annular grooves, applied in metal processing equipment, laser welding equipment, manufacturing tools, etc., to achieve the effects of reducing single pulse energy, controlling area, and high precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

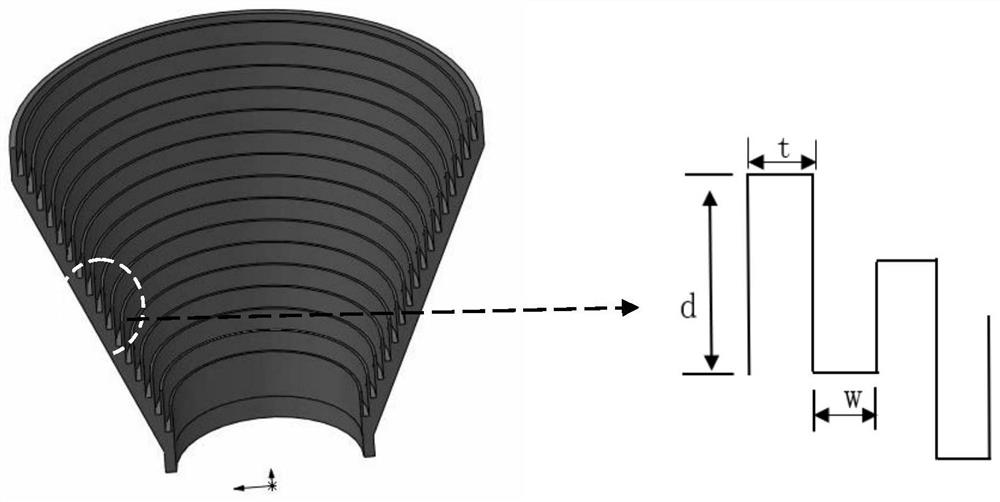

Image

Examples

Embodiment 1

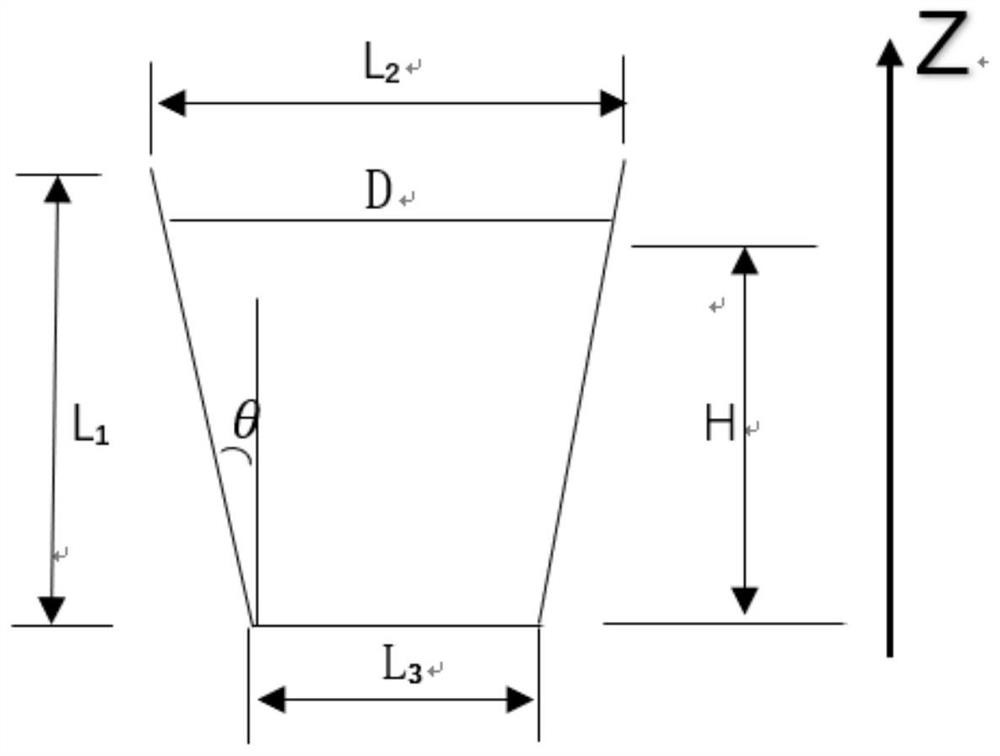

[0038] Embodiment one, such as image 3 As shown, when the tooth width t is each downward movement of the laser focus, the laser focus height H n for:

[0039] h n =H 0 -nt,n=0,1,2,... (3)

[0040] Ring groove diameter: D n =2(H 0-nt).tan14°+4,n=0,1,2,…(4)

[0041] where H 0 (H 0 ≤ L 1 ) is the starting height of the focal point, and n is the number of annular grooves.

[0042] In this embodiment, take H 0 =L 1 =10mm, at the same time design tooth width t=0.2mm, according to formula (3), focus height H 1 、H 2 、H 3 , ..., which are 9.8mm, 9.6mm, 9.4mm, ...; according to formula (4), the corresponding annular groove diameter D 1 、D 2 、D 3 , ..., followed by 7.9mm, 7.8mm, 7.7mm, ....

[0043] Using 532nm picosecond pulse laser, 2.5D scanning galvanometer, power 15W, scanning speed 250mm / s, repetition frequency 2500KHz, processing times 500 times. When processing the first groove, find point O through three-point positioning, and input focus height H 1 =9.8mm, ...

Embodiment 2

[0044] Embodiment two, such as image 3 As shown, when the tooth width t is each upward movement of the laser focus, the laser focus height H n for:

[0045] h n =H 0 +nt,n=0,1,2,... (5)

[0046] Ring groove diameter: D n =2(H 0 +nt).tan14°+4,n=0,1,2,…(6)

[0047] where H 0 (H 0 ≤ L 1 ) is the starting height of the focal point, and n is the number of annular grooves.

[0048] In this embodiment, take H 0 =3mm, at the same time design tooth width t=0.1mm, according to formula (5), focus height H 1 、H 2 、H 3 , ..., which are 3.1mm, 3.2mm, 3.3mm, ...; according to formula (6), the corresponding annular groove diameter D 1 、D 2 、D 3 , ..., followed by 5.55mm, 5.6mm, 5.65mm, ....

[0049] Using 532nm picosecond pulse laser, 2.5D scanning galvanometer, power of 15W, scanning speed of 250mm / s, repetition frequency of 3500KHz, and processing times of 500 times. When processing the first groove, find point O through three-point positioning, and input focus height H ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com