Light emitting diode (LED) assembled screen

A technology of LED assembled screen and LED chips, which is applied in the direction of identification devices, instruments, electrical components, etc., can solve the problems of inflexible installation of LED display screens, achieve good waterproof and dustproof effects, and reduce weight and volume.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be described in detail below with reference to the accompanying drawings and embodiments.

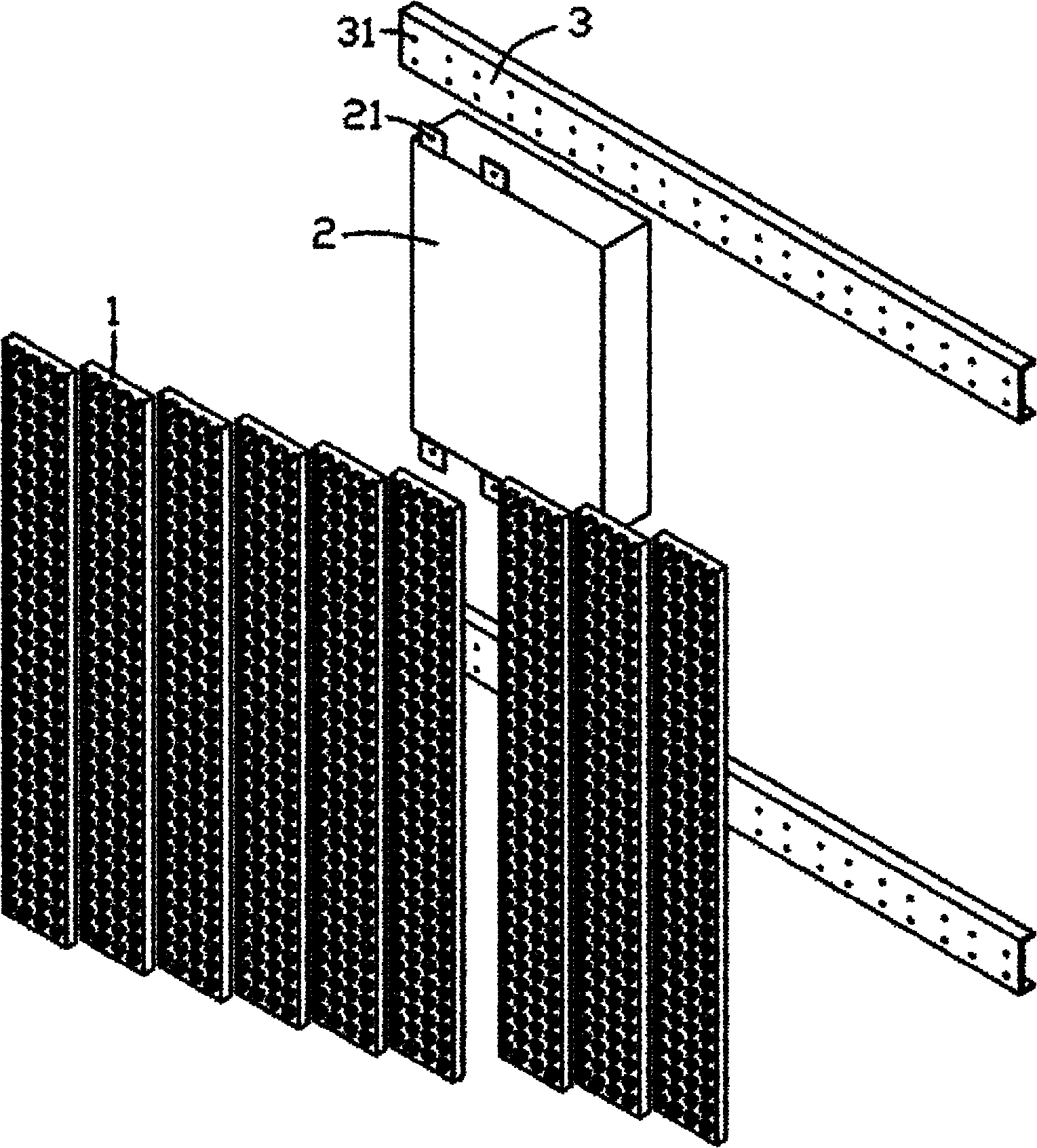

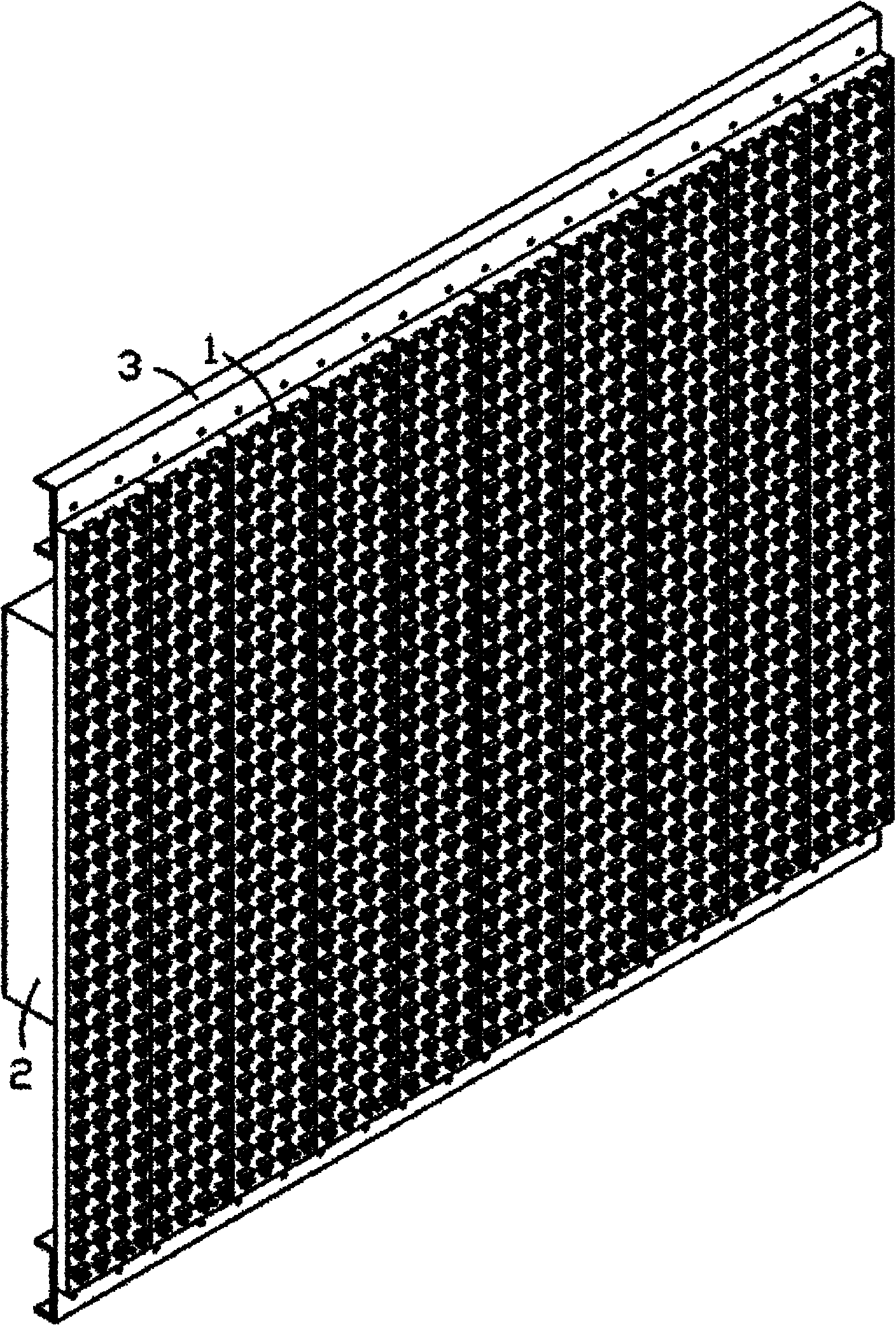

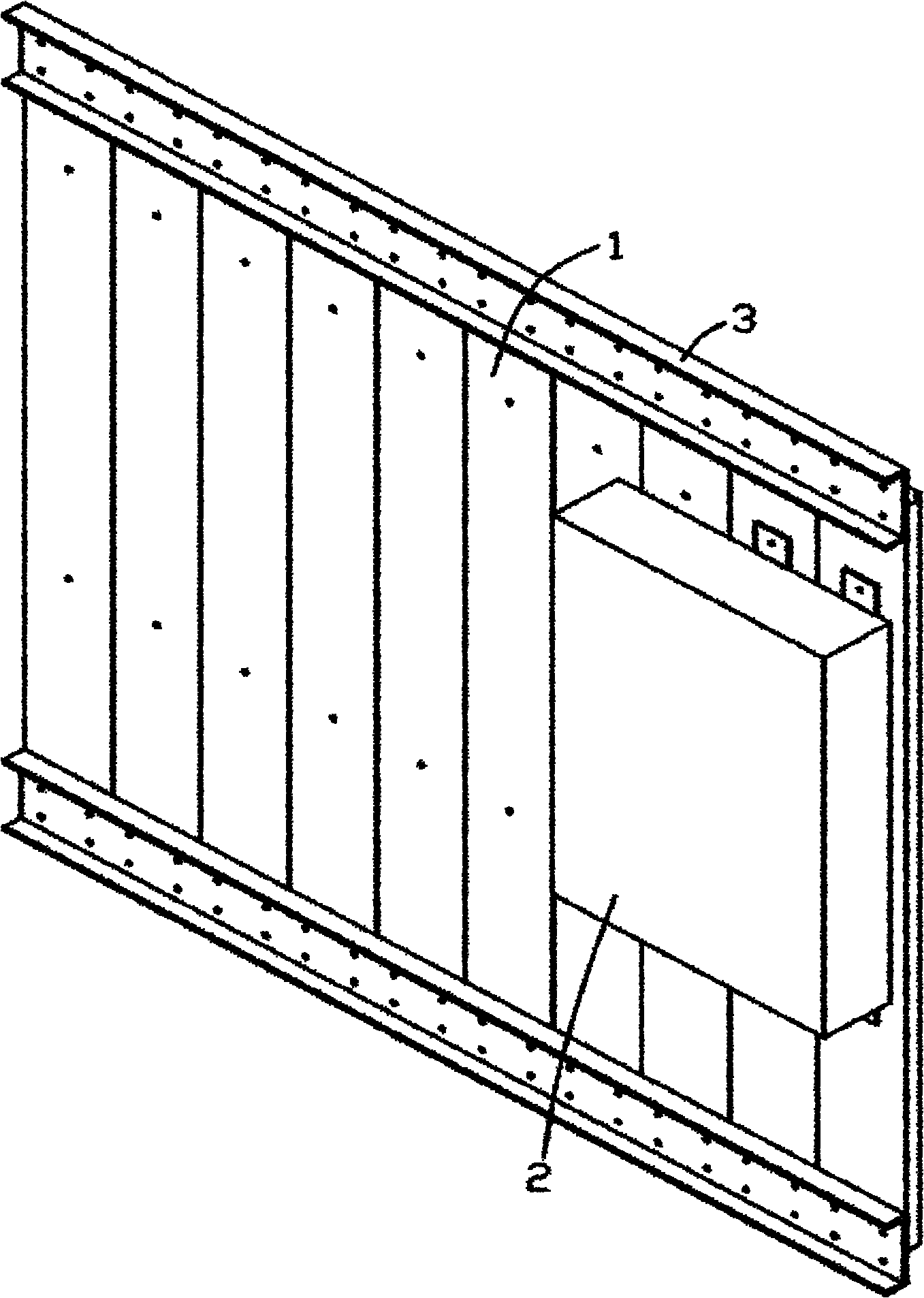

[0031] see Figure 1 to Figure 3 , the LED assembly screen of the embodiment of the present invention. The LED assembly screen includes: an LED display module 1 , a control box 2 and a frame 3 .

[0032] The control box 2 includes at least two independent output interfaces (not shown), and each output interface is connected to an LED display module 1 .

[0033] The at least two LED display modules 1 are spliced and fixed on the frame 3 .

[0034] and see Figure 4 The LED display module 1 includes: a box body 11 , a circuit board 12 , an LED chip 14 , a driving chip 15 , a potting glue 16 and an input interface 18 .

[0035] The driving chip 15 and a plurality of LED chips 14 are disposed on the circuit board 12 , and the driving chip 15 is respectively connected to the LED chip 14 and the input interface 18 .

[0036] The input interface 18 is a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com