Leaf surface brightening agent for foliage plants and preparation method

A technology of foliage plants and brighteners, applied in botany equipment and methods, plant preservation, application, etc., can solve problems such as easy adhesion of dust, dirt, harm to people and the environment, blockage of stomata on plant leaves, etc. Achieve good natural luster, improve ornamental value, and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

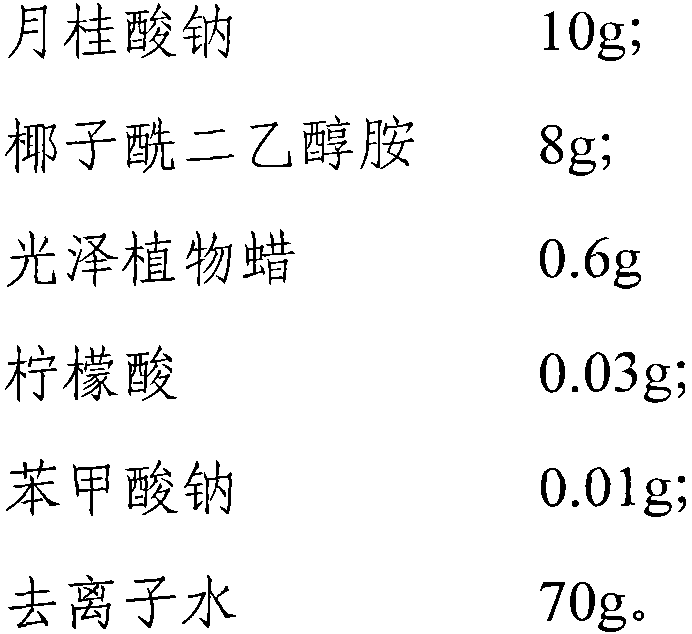

Embodiment 1

[0019] Take willow leaves to dry, weigh 10g, add 300ml of water, extract at 45°C for 6 hours, repeat 3 times, filter, combine the filtrates, add 850ml of 90% ethanol to the filtrate, let stand for 24 hours, centrifuge, take the The clear liquid was concentrated under reduced pressure at 45°C to recover the solvent to obtain 1.8 g of extract. Dissolve the extract with 100ml of distilled water, adsorb with HZ820 macroporous resin for 24 hours, elute with 800ml of 90% ethanol after eluting with 800ml of distilled water, and concentrate the ethanol eluate to dryness under reduced pressure to obtain 0.58g of glossy vegetable wax

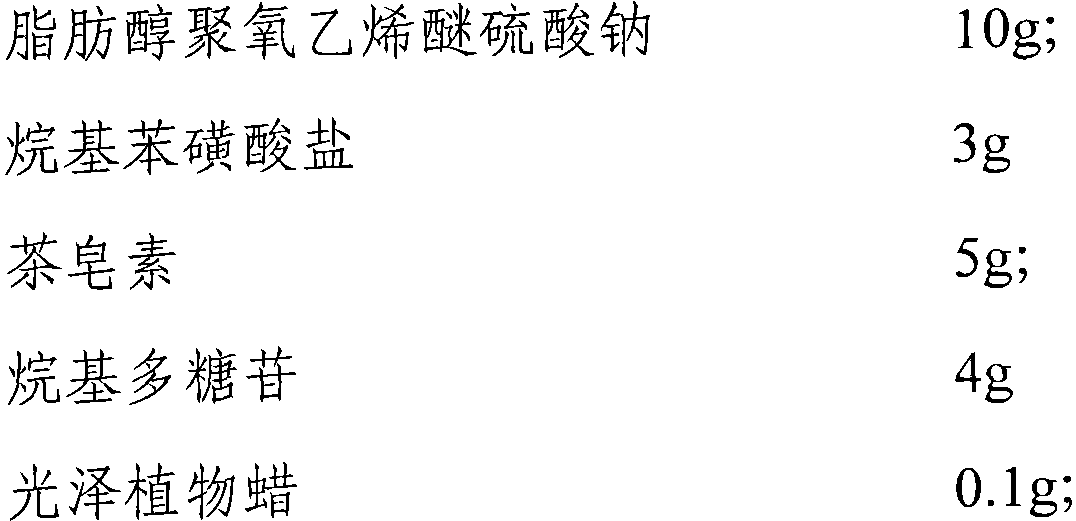

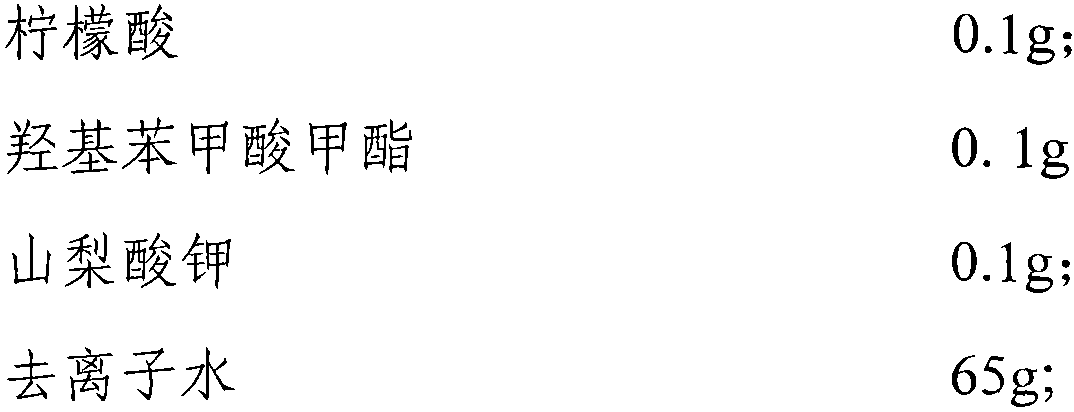

Embodiment 2

[0021] Take willow leaves to dry, weigh 10g, add 200ml of water, extract at 30°C for 5 hours, repeat twice, filter, combine the filtrates, add 400ml of 80% ethanol to the filtrate, let it stand for 24 hours, centrifuge, take the The clear liquid was concentrated and recovered under reduced pressure at 45°C to obtain 1.7 g of extract. Dissolve the extract with 100ml of distilled water, adsorb with HZ841 type macroporous resin for 24 hours, elute with 700ml of 85% ethanol after eluting with 700ml of distilled water, and concentrate the ethanol eluate to ten under reduced pressure to obtain 0.53g of glossy vegetable wax.

Embodiment 3

[0023] Take willow leaves to dry, weigh 10g, add 350ml of water, extract at 40°C for 7 hours, repeat twice, filter, combine the filtrates, add 700ml of 85% ethanol to the filtrate, let stand for 24 hours, centrifuge, take the The clear liquid was concentrated under reduced pressure at 45°C to recover the solvent to obtain 2.1 g of extract. Dissolve the extract with 100ml of distilled water, adsorb with HZ818 type macroporous resin for 24 hours, elute with 1000ml of 95% ethanol after elution with 1000ml of distilled water, and concentrate the ethanol eluent under reduced pressure to obtain 0.60g of glossy vegetable wax.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com