Material sorting method

A sorting, percentage technology, applied in the direction of analyzing materials, using wave/particle radiation for material analysis, sorting, etc., can solve problems such as water pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

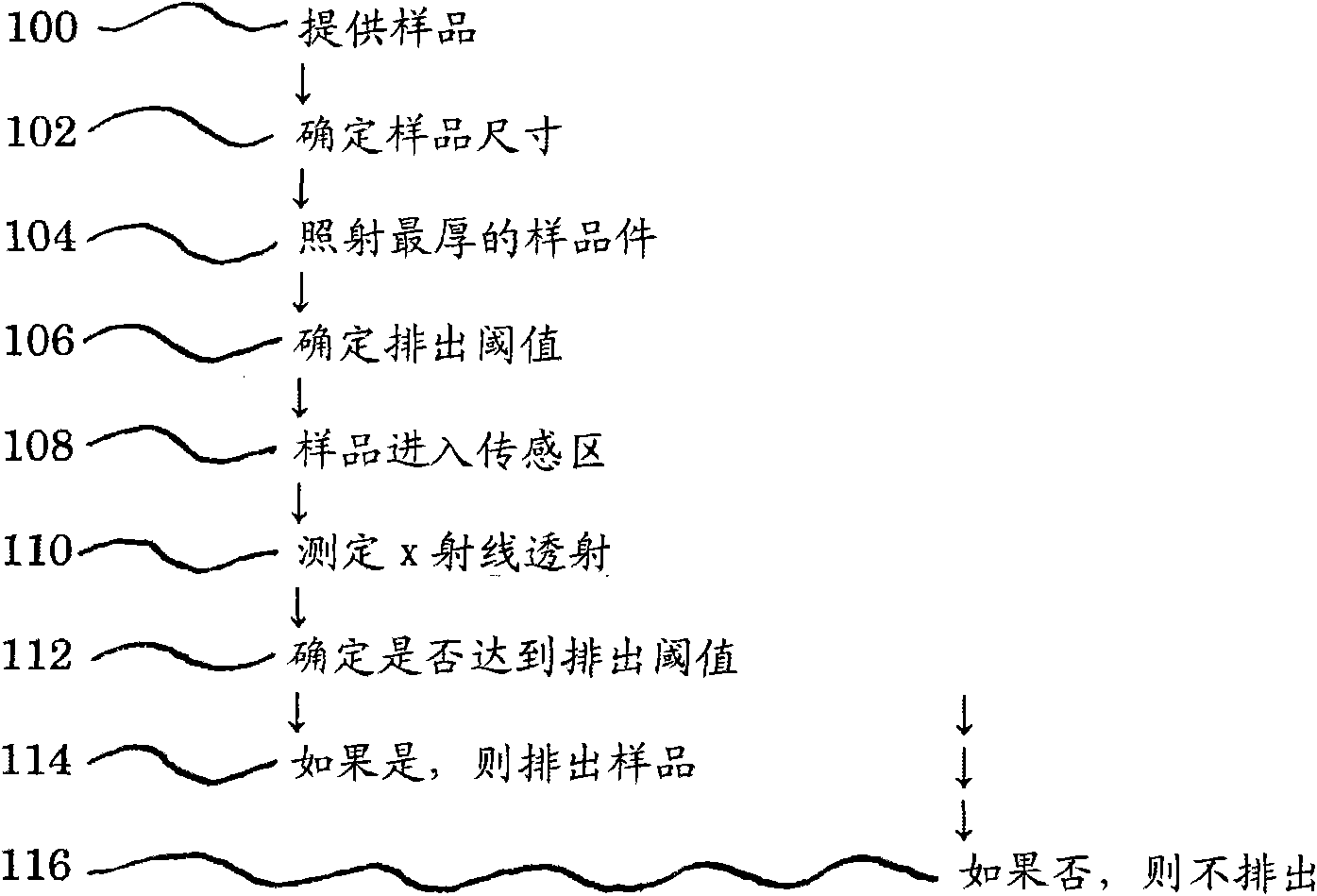

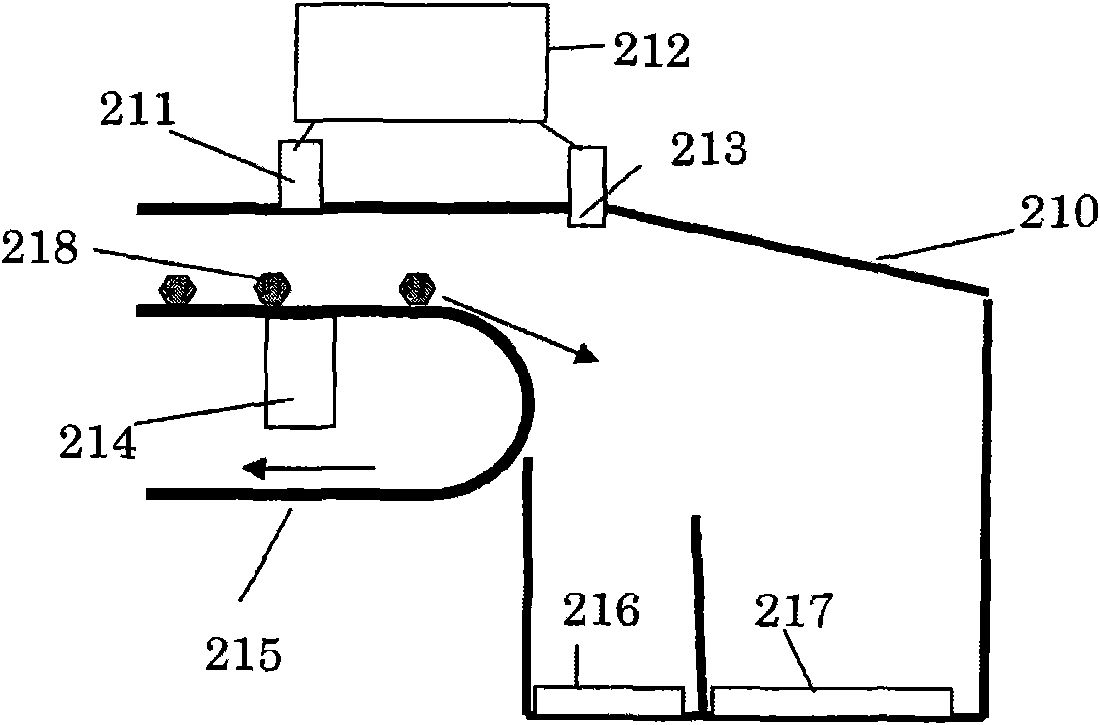

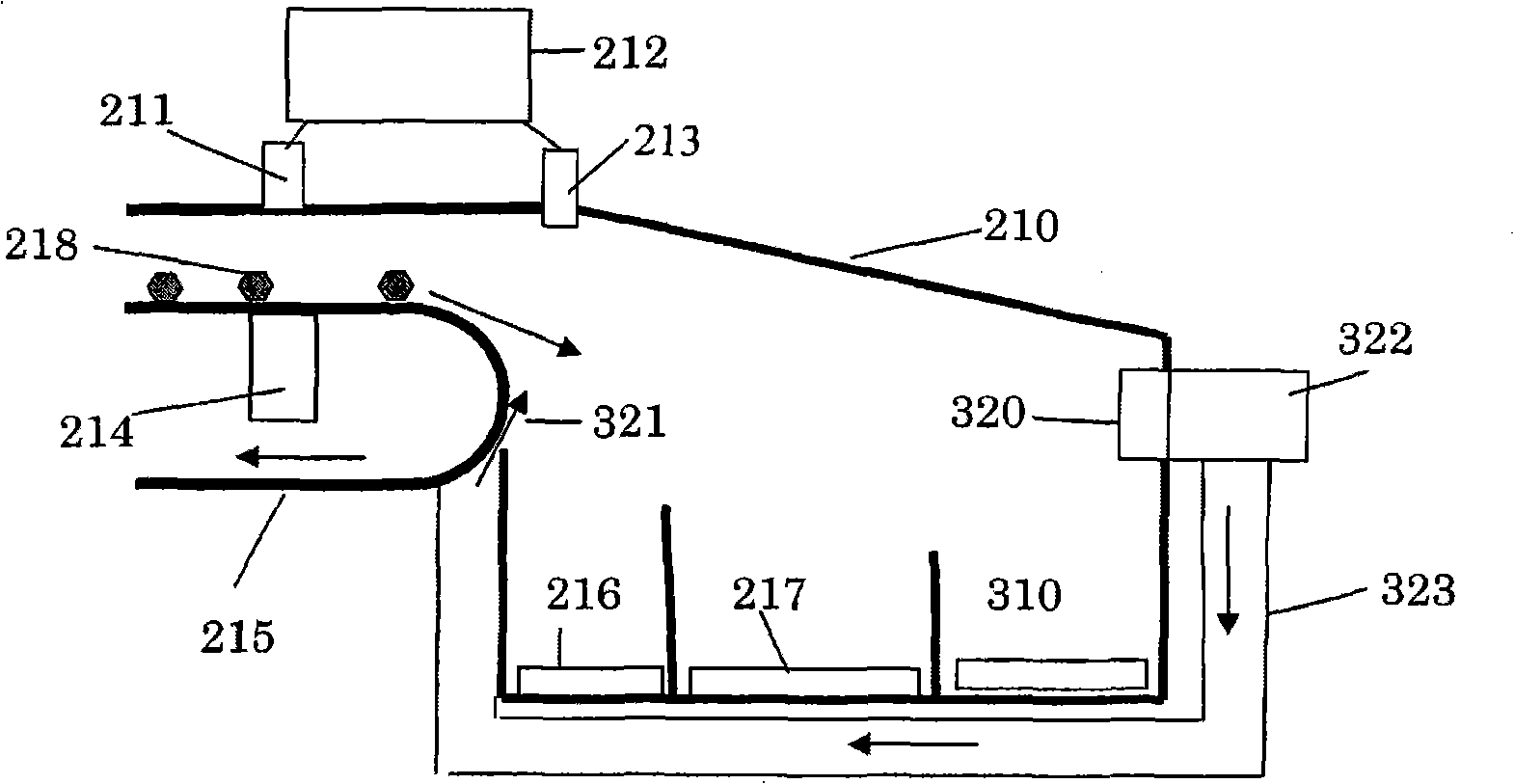

Method used

Image

Examples

Embodiment 1

[0045] Example 1: Linear Absorption Coefficient

[0046] Figure 7 Pyrite (FeS), coal, and silica (SiO 2 ) mass absorption coefficient (μ). Also their densities are shown. Note that coal is a mixture of carbon and hydrocarbons, and there is no NIST "standard" for coal. Thus, the X-ray absorption coefficient for coal is the NIST data for graphite corrected to a coal density of 1.2 grams per cubic centimeter (g / cc). As shown elsewhere herein, coal absorbs much less than pyrite among silicates for X-rays between 8 and 20 kiloelectron volts (KeV). use Figure 7 The information in shows how contaminants can be separated from coal.

Embodiment 2

[0047] Example 2: Percent X-ray transmission at different energies

[0048] The methods disclosed herein use x-ray energy that allows the selection of contaminants for removal while providing detectable transmission through the coal. As a first step, the size of the raw coal is reduced to less than 5 cm in order to provide significant transmission through the coal sample, while opaque contaminants such as sulfides and silicates pass through the X-ray transmission percentage of these materials. decrease to be detected. Figure 8The percent transmission calculated from the NIST absorption coefficient information is shown in .

[0049] Such as Figure 8 Best visible in medium, coal transmits X-ray energy extremely easily compared to what other materials allow. For example, it is calculated that the use of X-ray energy at the 15KeV level results in 56.6% transmission through coal with a thickness of 1 cm, whereas a contaminant with a thickness of only 1 mm has lower transmissio...

Embodiment 3

[0050] Example 3: Separation of Contaminants from Coal

[0051] The following method was performed on a 100 lb wet washed coal sample to separate contaminants from the coal. The samples were dried in the sun to remove moisture remaining from the wet washing step. After sun drying, the samples were reduced to individual pieces smaller than 10 cm in size. A sample was placed in an X-ray scanning device (Baggage Scanner Model No. 7555 commercially available from Smiths Detection, Danbury, CT). The X-ray apparatus is tuned to detect X-ray energies up to 160KeV. The transmission through each sample block was measured at two energy ranges. X-ray detectors receiving transmissions of X-ray energy are set such that transmissions through the coal correlate with transmissions at both energy ranges giving atomic numbers approximately less than 10. As noted in this application, these contaminants result in a reduced percent transmission of X-rays through the material, resulting in a hi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com