Method for improving control precision of coiling temperature

A technology for controlling precision and coiling temperature, applied in temperature control, metal rolling, manufacturing tools, etc., can solve the problem of frequent changes in product types, inability to simultaneously satisfy coiling temperature control precision and mechanical performance stability, and inability to adjust headers Water flow and other issues to achieve the effect of improving the coiling temperature control accuracy, reducing temperature fluctuations, and stabilizing the control system and model

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

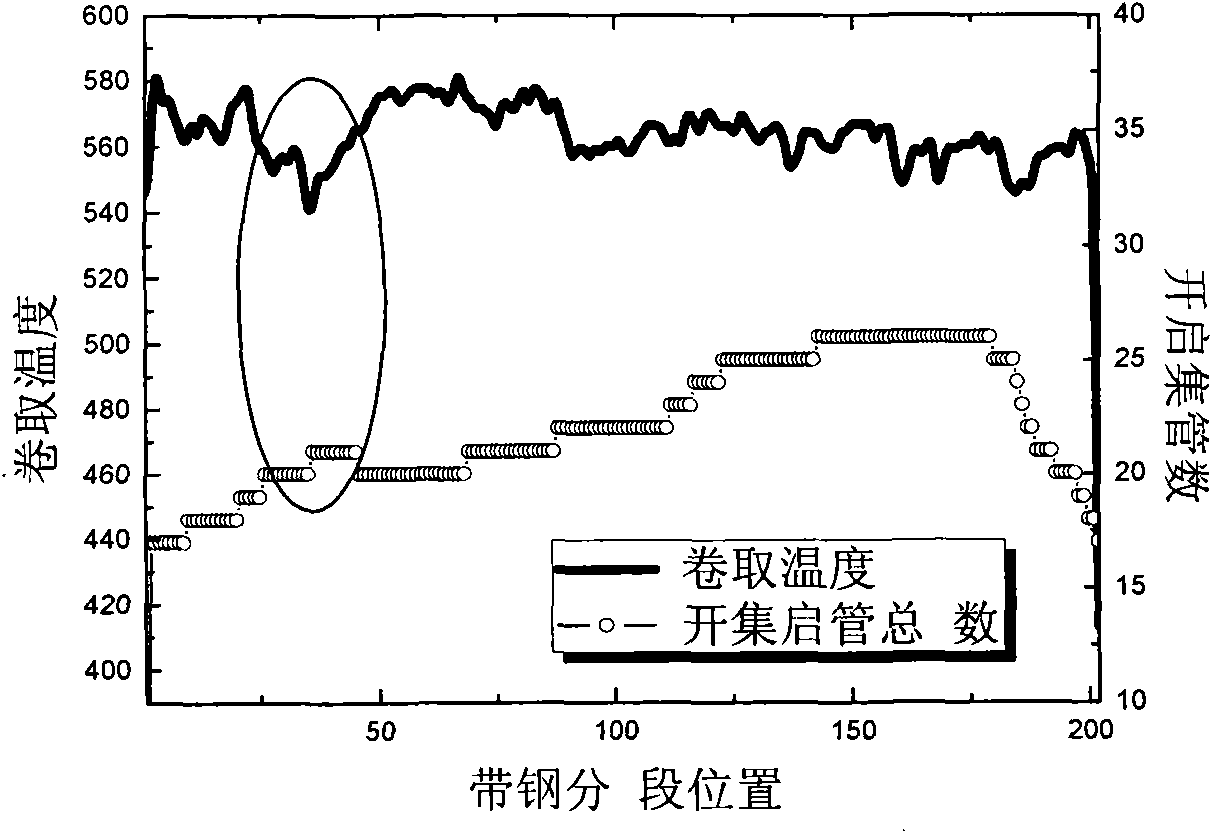

[0026] Taking silicon steel BWG with a thickness of 2.5mm as an example, the laminar flow cooling control system divides the strip steel into about 200 sections. The water volume of the pipe is 90m 3 / h, the water volume of the upper and lower headers of feedback control 21 and 22 is 47m 3 / h, there is a phenomenon that the coiling temperature of a certain section drops rapidly with the increase of the number of opened headers, such as figure 2 As shown, the standard deviation of the strip full-length coiling temperature is equal to 8.4.

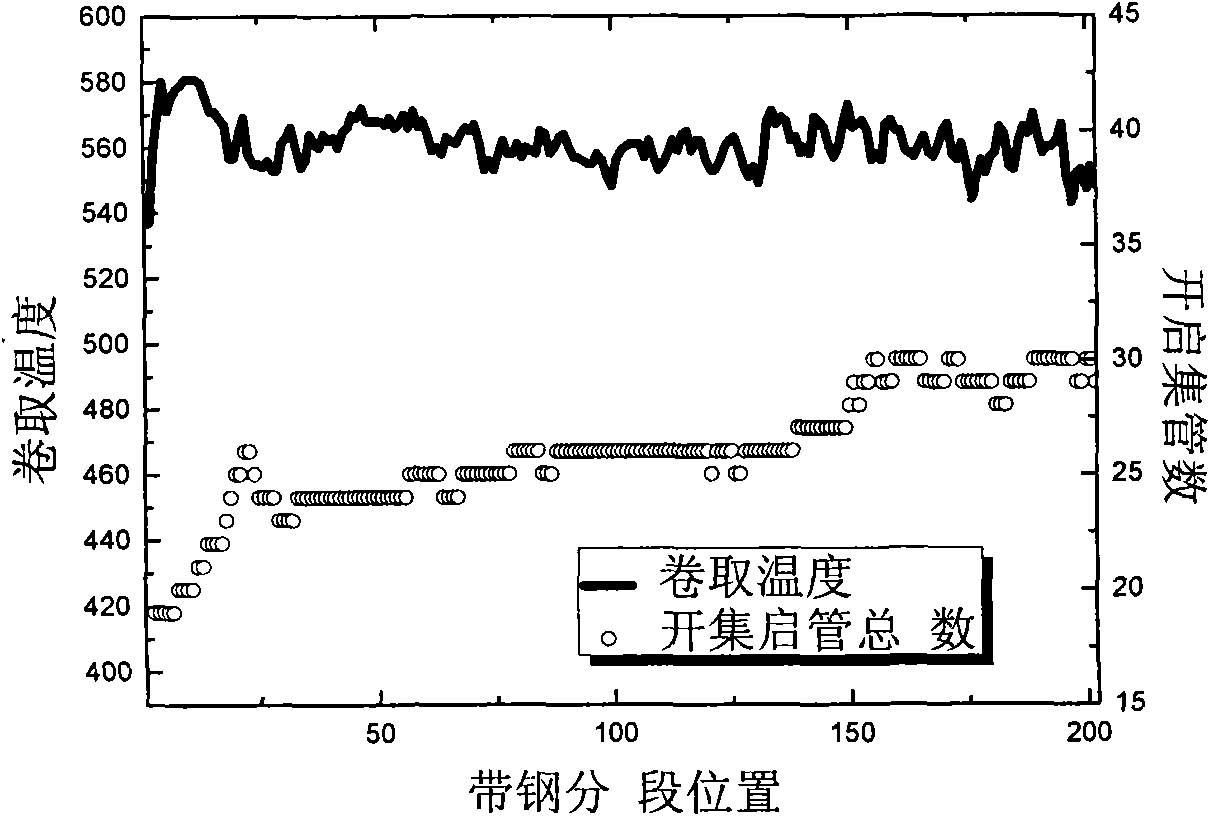

[0027] After configuring the water volume of each group of headers according to Table 1 and using the strategy of spraying water from the 11th group of headers, the feedforward control of the water volume of the 11-16 groups of upper headers is 80m 3 / h, the water volume of the header on the feedback control 21 and 22 is 35m 3 / h, feed-forward control 11-16 groups of lower header water volume 90m 3 / h, feedback control 21, 22 sets of lo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com