Staircase portal frame assembling fixture and assembling method thereof

A technology for assembling tooling and escalators, used in metal processing, manufacturing tools, metal processing equipment, etc., can solve the problems of no head glass clamping parts, inability to realize production line circulation, large size deviation, etc., to eliminate the waste of waiting for walking, Eliminate the steps of replacing tooling and solve the effect of large installation errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

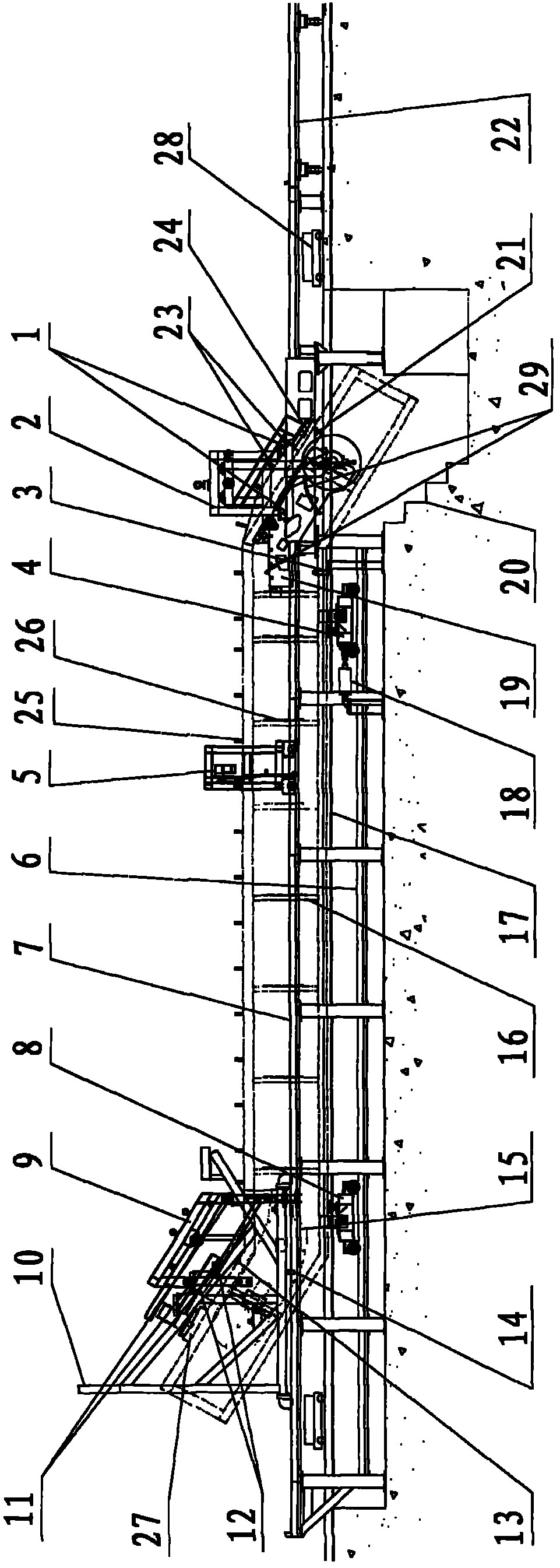

[0044] Attached below Figure 1-13 Further describe the detailed technical contents and embodiments of the present invention. The symbols and embodiments shown in the drawings should not be regarded as limitations on the technology of the present invention, and any expansion and addition on the basis of the present invention shall be regarded as the protection scope of the present invention.

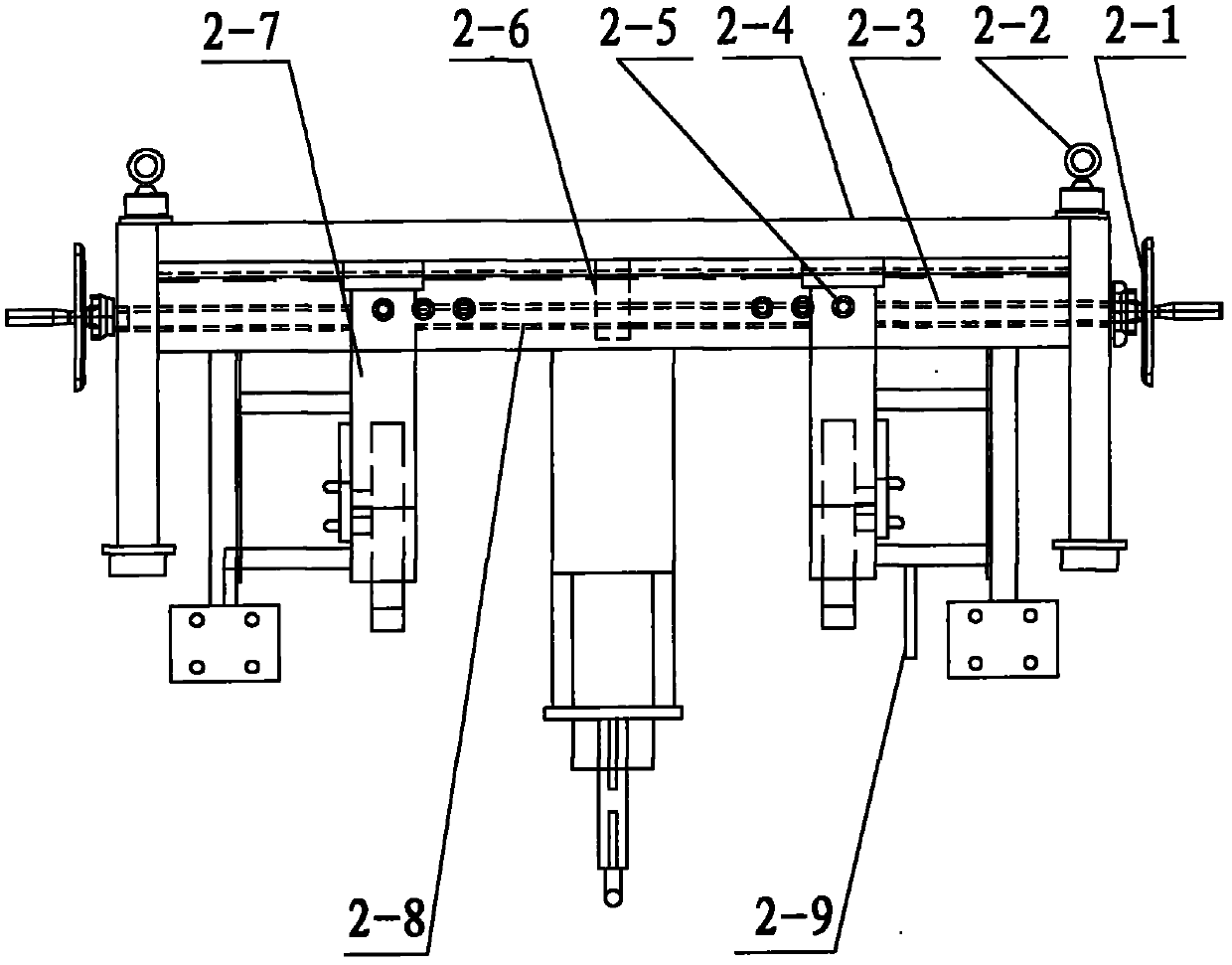

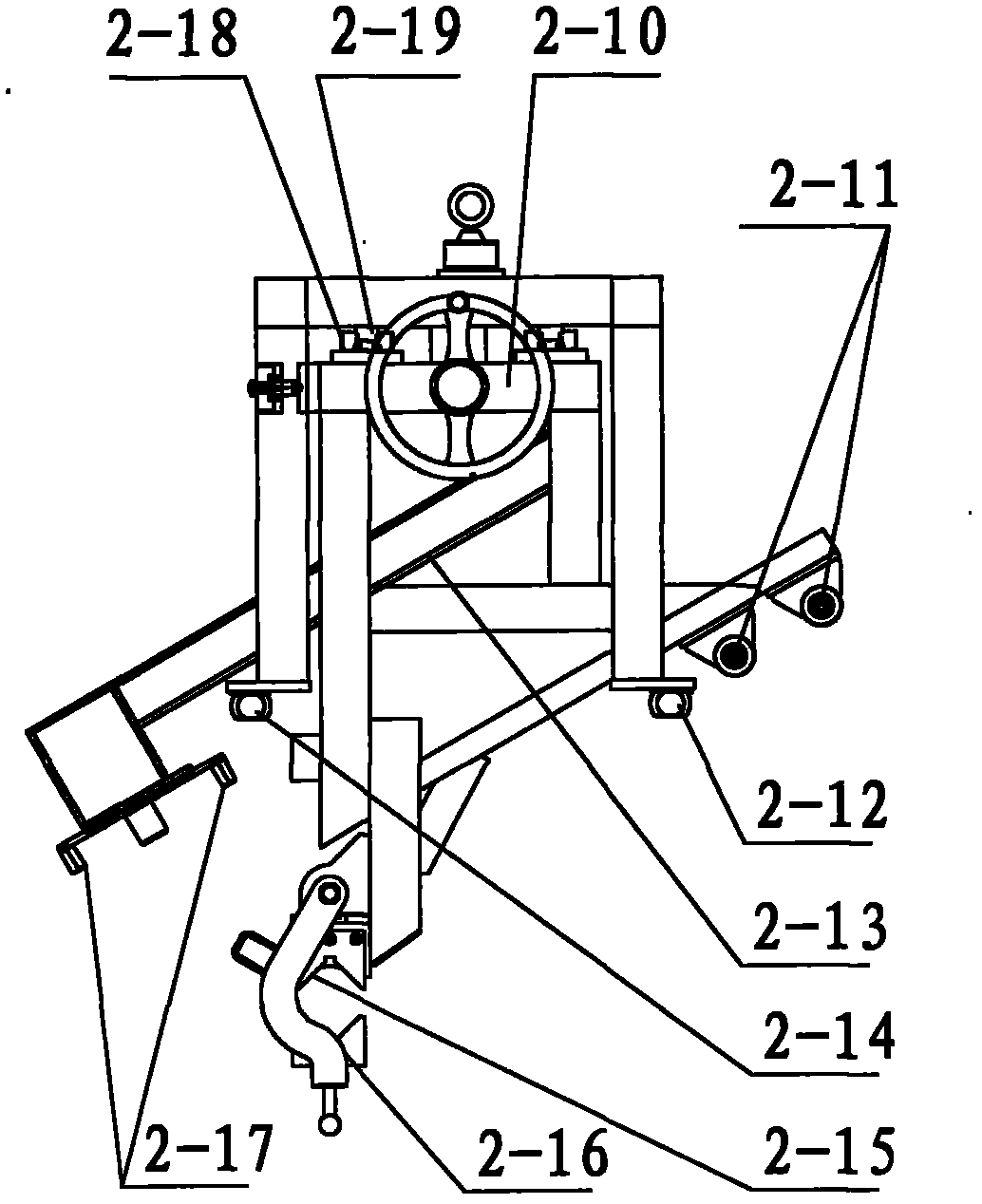

[0045] Refer to attached figure 1 As shown, the escalator gantry assembly tooling provided by the present invention includes: upper tooling positioning base 1, upper precision hoisting tooling 2, escalator truss longitudinal positioning base 3, upper clamping positioning trolley 4, middle gantry positioning trolley 5, clamping Tight positioning trolley guide rail 6, gantry guide rail 7, lower clamping positioning trolley 8, lower precision hoisting tooling 9, lower gantry positioning trolley 10, lower tooling positioning base 11, station transfer trolley 28, station transfer track 17. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com