Bionic anti-drag and noise-reducing high-speed pantograph

A pantograph and high-speed technology, which is applied in the field of bionic drag-reducing and noise-reducing high-speed pantographs, can solve the problems of restricting the speed of trains and failing to meet the noise requirements of high-speed trains, and achieve the goals of improving shedding, simple manufacturing process, and reducing interference Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

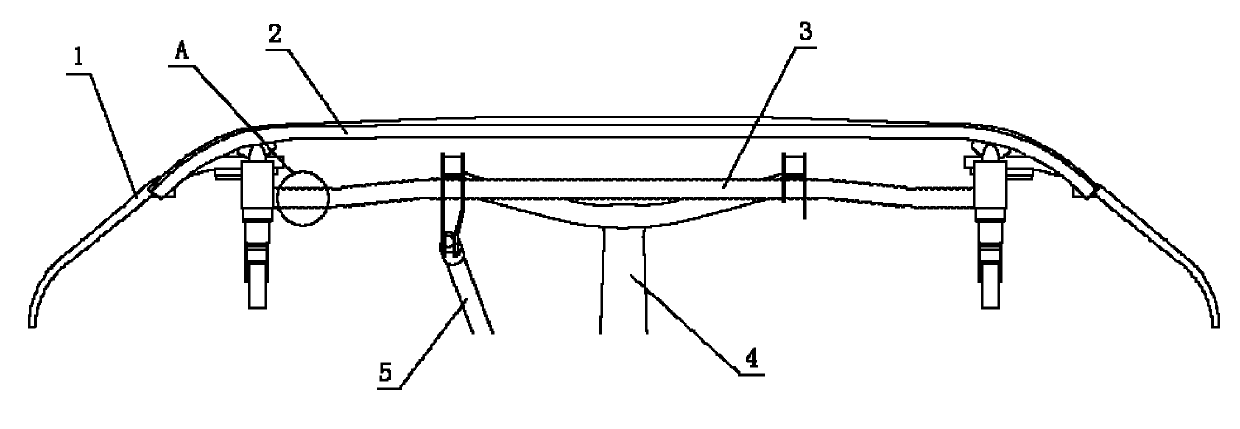

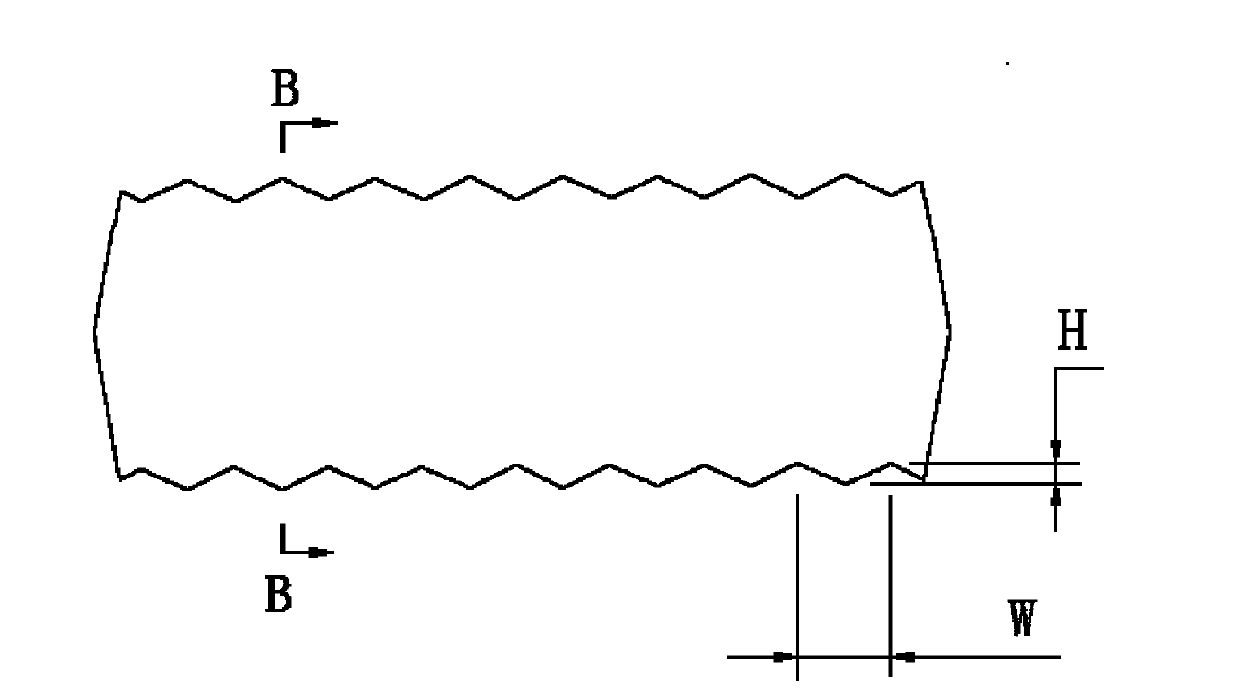

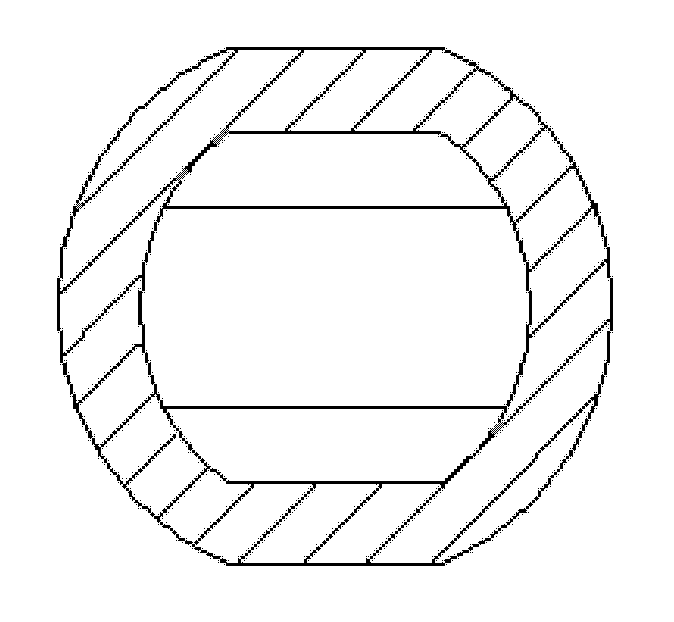

[0020] Such as Figures 1 to 3 As shown, a specific embodiment of the present invention is: the upper surface and the lower surface of the support rod 3 are made into a zigzag stripe surface, and the zigzag stripe unit body on the upper surface and the lower surface of the support rod 3 is symmetrical along the axis of the support rod Distribution, the width W of the zigzag stripe unit body is 1 cm, and the height H of the zigzag stripe unit body is 0.5 cm.

Embodiment 2

[0022] Such as figure 1 , 4 , 5, a specific embodiment of the present invention is: the upper surface and the lower surface of the support rod 3 are made into a zigzag stripe surface, and the upper surface and the lower surface of the support rod 3 have a zigzag stripe unit body along the axis of the support rod. Asymmetric distribution, the width W of the zigzag stripe unit body is 2 cm, and the height H of the zigzag stripe unit body is 0.5 cm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com