Method for measuring continuously-variable load precision of large-scale floating dock in floating state

A technology of precision measurement and floating dock, which is applied in the direction of measuring devices, instruments, and marine transportation, which can solve the problems of increasing the time for pulling and launching the hull, consuming manpower and material resources, and long service life of the floating dock, so as to improve the efficiency of launching and moving , save working hours, ensure deformation accuracy and launch safety effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

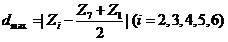

[0028] Attached below Figures 2 to 7 The preferred embodiment of the present invention is further described. In order to ensure that the hull 5 is in the process of launching, the alignment accuracy of the level and centerline of the floating dock slideway 2 and the slipway slideway 2, two total station electronic speed measuring instruments (Electronic Total Station, hereinafter referred to as the total station) 61 and 62 respectively measure the deck plane of the floating dock 1 and the deck plane of the hull 5, and feed back the deformation data generated by the two during the pulling process of the hull 5 based on a unified benchmark. The central control room, and instructs the central control room to adjust the water pressure or drainage of the ballast tank 3 of the floating dock 1.

[0029] Specific steps are as follows:

[0030] (1) Roughly adjust the loading of the floating dock before pulling and moving, see figure 2 and image 3 , docking the floating dock 1 and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com