Axle assembly transportation fixing frame

A fixed frame and assembly technology, which is used in transportation and packaging, external frames, assembly vehicles, etc., can solve the problem that the support structure cannot fully and reasonably utilize the space, and achieves the goal of reducing the center, improving the packing density, and increasing the chassis area. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

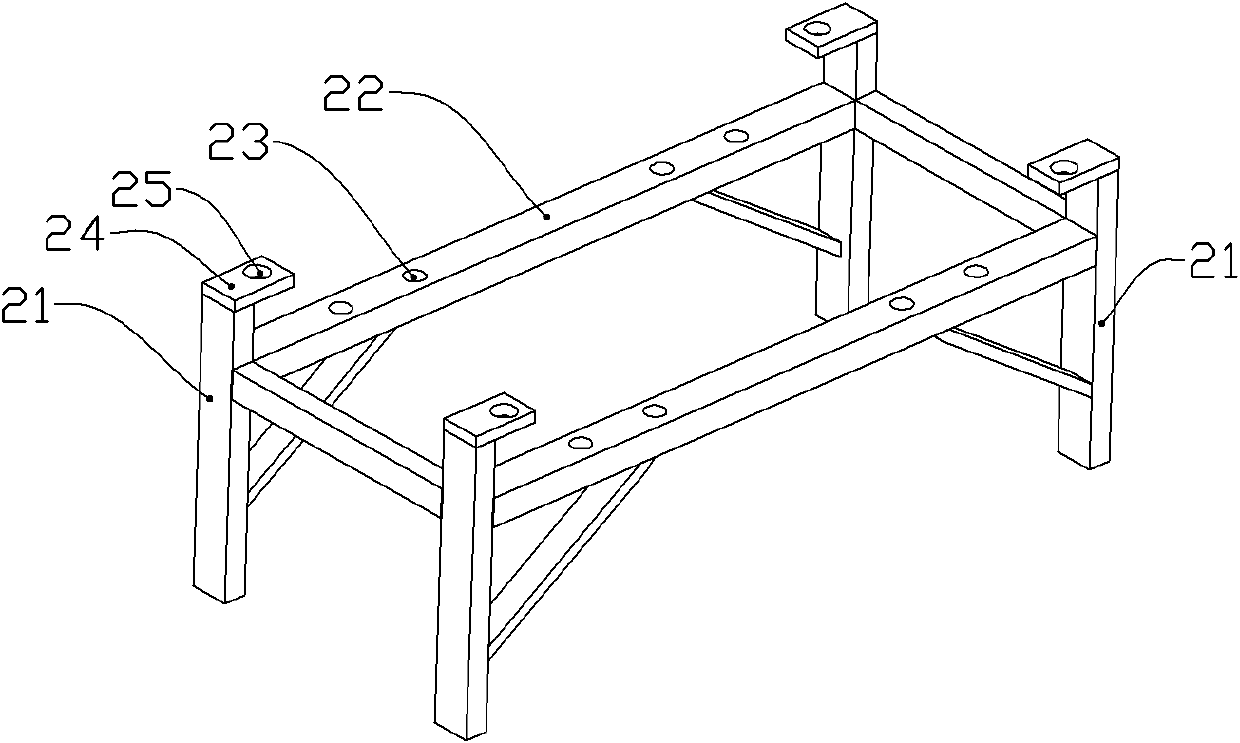

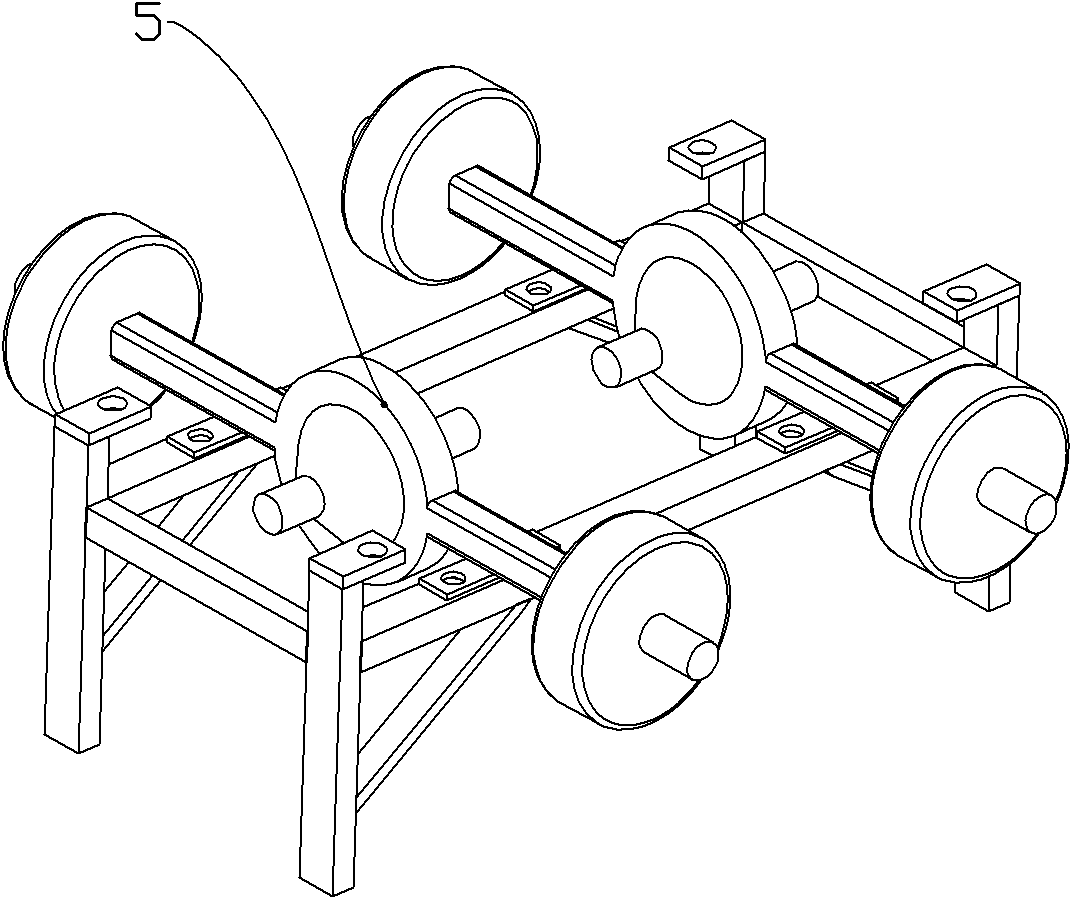

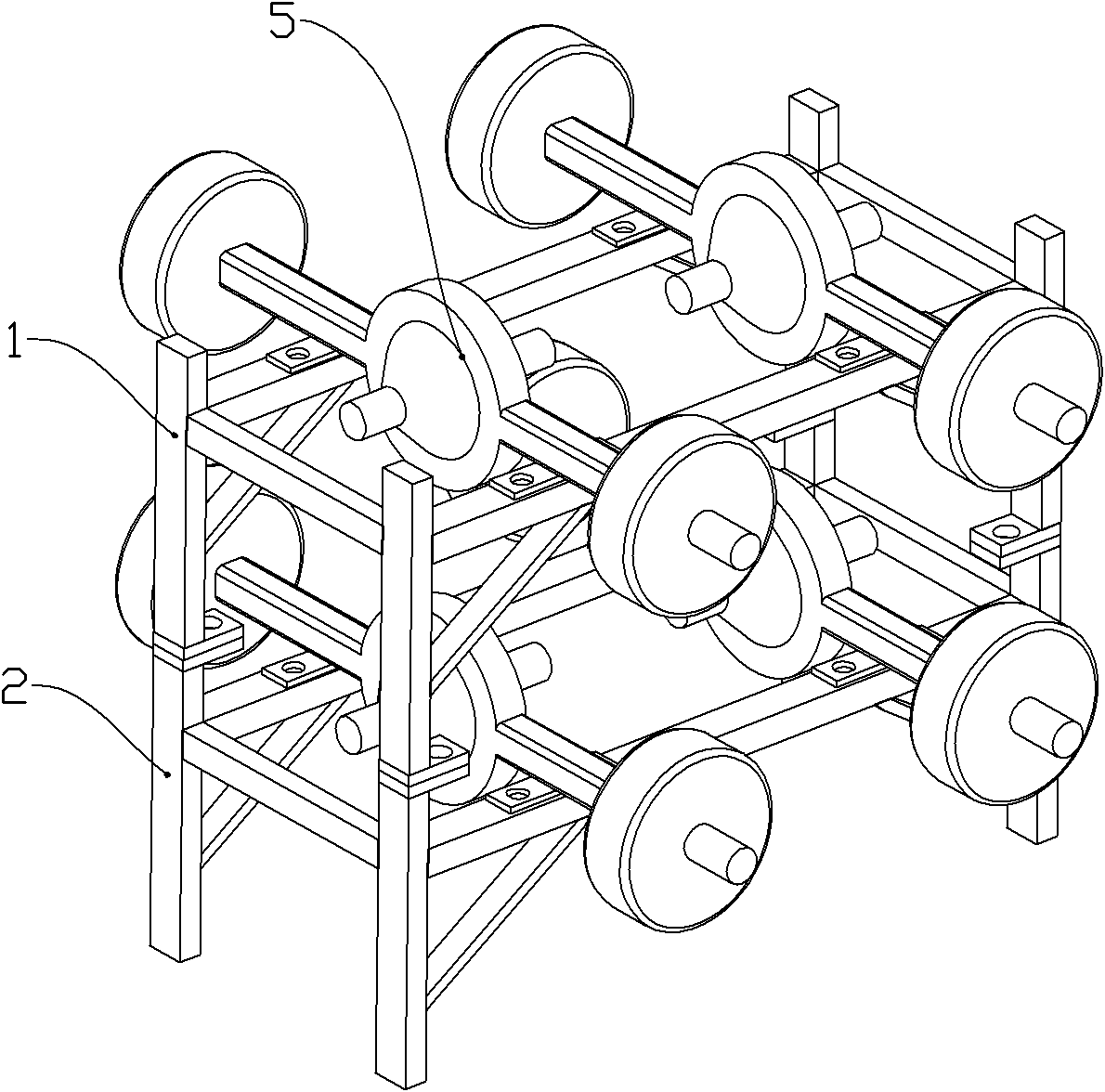

[0020] Such as Figure 1~3 As shown, this kind of vehicle axle assembly transport fixing frame includes two support bodies with the same structure arranged in the upper and lower positions, which are respectively the upper support body 1 and the lower support body 2, and the upper and lower support bodies are fixedly connected by bolts to form two floors.

[0021] The lower support body 2 includes four uprights 21 and crossbeams 22 connecting the uprights. The uprights and crossbeams are angle steel or square steel pipes, which are welded to each other to form a frame. Matching positioning holes 23, the positioning holes are preferably adjustable long holes, and the positioning holes are in pairs, which can fix two axle assemblies at the same time to form two placement stations; the upper end of the column 21 is fixed with a fixed piece 24 , The fixed piece is provided with bolt hole 25.

[0022] The structure of the upper support body is basically the same as that of the lo...

Embodiment 2

[0025] Such as Figure 4 As shown, the difference from Embodiment 1 is that there are three placement stations for the axle assembly on each supporting body.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com