Technique for preparing agricultural potassium sulfate by utilizing kaliophilite powder

A technology of kalephine powder and potassium sulfate, which is applied in the field of producing agricultural potassium sulfate, can solve the problems of complicated reaction process conditions and high raw material costs, and achieve the effects of mild reaction conditions, simple process and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

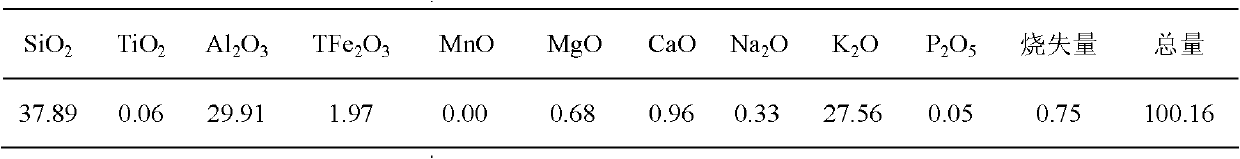

[0013] Table 1 The chemical composition analysis results of kalephine powder w B %

[0014]

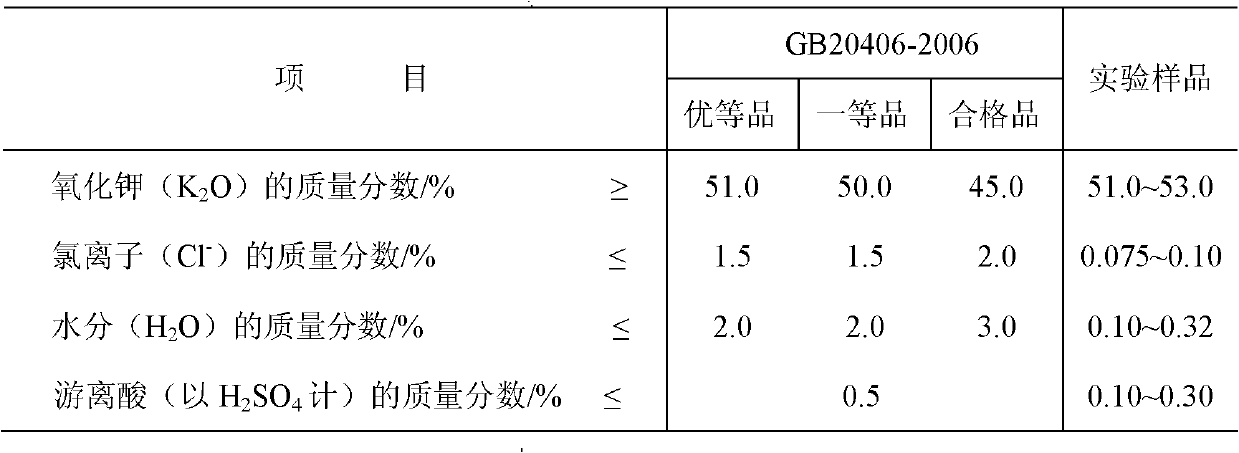

[0015] The chemical composition analysis results of the kalite powder are shown in Table 1. Take by weighing 500g of kalephine powder, 2500g of distilled water, 400g of sulfuric acid with a mass concentration of 30%, mix uniformly, place in an acid-dissolving reactor together, adjust the reaction temperature of the reactor to be 60°C, and the stirring speed is 200r / min, After reacting for 3h, it was separated by filtration. It is determined that the dissolution rate of potassium oxide in the kacryptite powder raw material is 95.5wt%, and the dissolution rate of aluminum oxide is 0.06wt%. The potassium sulfate filtrate obtained by filtering is placed in a crystallizer, evaporated and crystallized under the condition of 115° C., and an agricultural potassium sulfate product is obtained. The three repeated test samples were compared with the indicators in the National Standard for ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com