Ultra-black plush polish processing agent used for synthetic leather and preparation method thereof

A synthetic leather and treatment agent technology, applied in fiber processing, textiles and papermaking, etc., can solve the problems of poor viscosity, stability, poor hand feel, poor hand feel of synthetic leather, dissolution of the bottom layer of synthetic leather, etc., and achieves good matting effect. Good overall effect and cost-increasing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

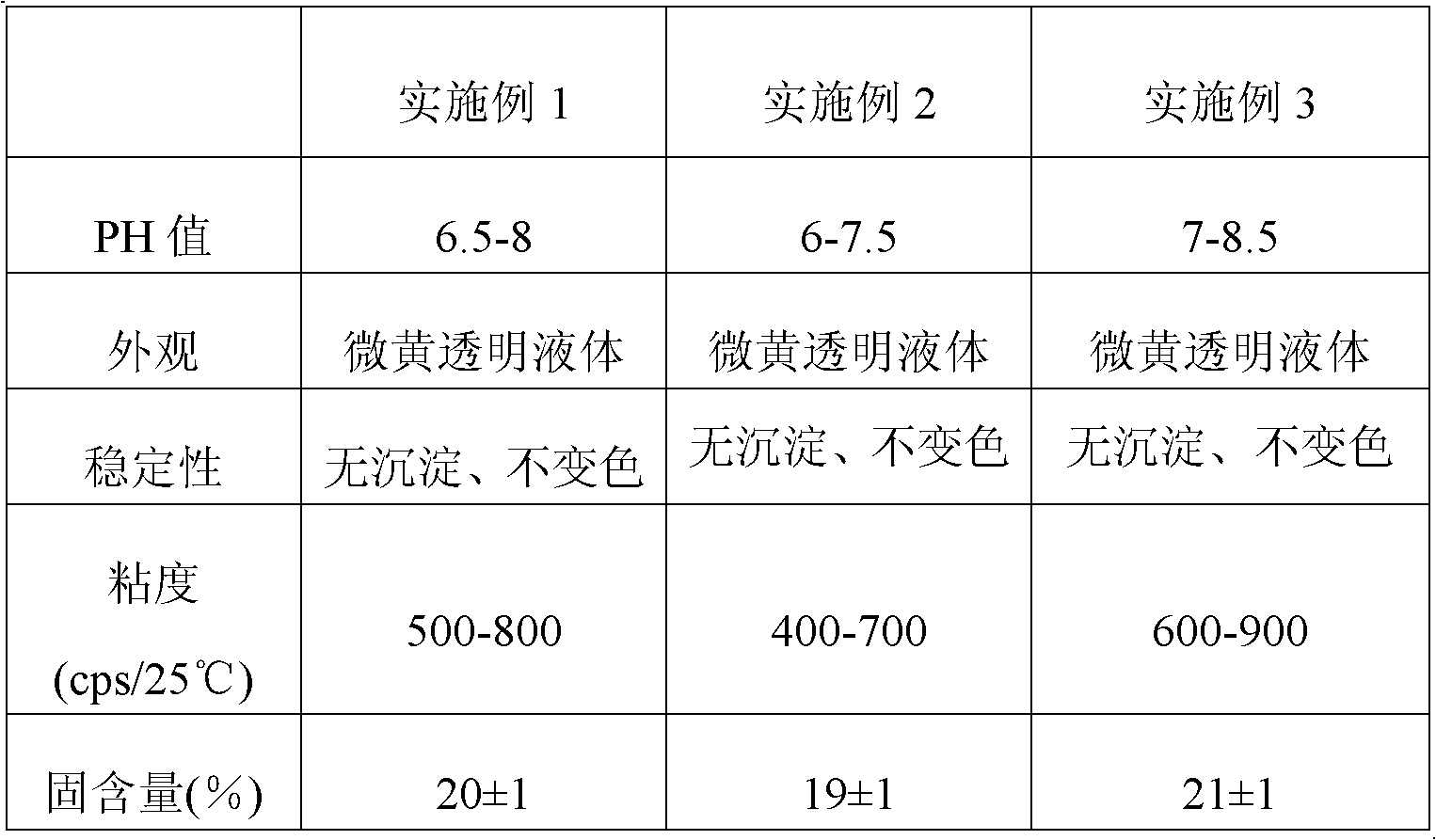

Embodiment 1

[0023] A kind of super black velvet feeling ironing treatment for synthetic leather consists of 60 parts by weight of modified anti-yellowing polyurethane resin, 20 parts by weight of ethyl acetate, 15 parts by weight of isopropanol, 4 parts by weight of polyurethane color beads, and silica matting powder 5 parts by weight, 1 part by weight of modified siloxane, 1.2 parts by weight of leveling agent, and 2.8 parts by weight of water repellent.

[0024] At normal temperature and pressure, 50 parts by weight of modified anti-yellowing polyurethane resin, 20 parts by weight of ethyl acetate, 15 parts by weight of isopropanol, 5 parts by weight of silica matting powder, 4 parts by weight of Polyurethane color beads, after stirring at room temperature for 30 minutes, filter; add 1 part by weight of modified siloxane, 1.2 parts by weight of leveling agent, and 2.8 parts by weight of water repellent to the mixture obtained in the previous step, and stir evenly at room temperature; Ad...

Embodiment 2

[0027] A special black velvet feeling ironing treatment agent for synthetic leather consists of 40 parts by weight of modified anti-yellowing polyurethane resin, 20 parts by weight of ethyl acetate, 20 parts by weight of isopropanol, 3 parts by weight of polyurethane color beads, and silica extinction 3 parts by weight of powder, 1 part by weight of modified siloxane, 1 part by weight of leveling agent, and 1 part by weight of water repellent.

[0028] At normal temperature and pressure, 30 parts by weight of modified anti-yellowing polyurethane resin, 20 parts by weight of ethyl acetate, 20 parts by weight of isopropanol, 3 parts by weight of silica matting powder, 3 parts by weight of Polyurethane color beads, after stirring at room temperature for 30 minutes, filter; add 1 part by weight of modified siloxane, 1 part by weight of leveling agent, and 1 part by weight of water repellent to the mixture obtained in the previous step, and stir evenly at room temperature; Add the ...

Embodiment 3

[0031] A special black velvet feeling ironing treatment agent for synthetic leather consists of 60 parts by weight of modified anti-yellowing polyurethane resin, 30 parts by weight of ethyl acetate, 30 parts by weight of isopropanol, 5 parts by weight of polyurethane color beads, and silica extinction 5 parts by weight of powder, 4 parts by weight of modified siloxane, 3 parts by weight of leveling agent, and 3 parts by weight of water repellent.

[0032] At normal temperature and pressure, 50 parts by weight of modified anti-yellowing polyurethane resin, 30 parts by weight of ethyl acetate, 30 parts by weight of isopropanol, 5 parts by weight of silica matting powder, 5 parts by weight of Polyurethane color beads, after stirring at room temperature for 30 minutes, filter; add 4 parts by weight of modified siloxane, 3 parts by weight of leveling agent, and 3 parts by weight of water repellent to the mixture obtained in the previous step, and stir evenly at room temperature; Ad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com