Electron beam monitoring device for electron accelerator

An electron accelerator and electron beam technology, applied in the direction of electrical components, accelerators, etc., can solve the problems of damage and destruction of vacuum pipelines, and achieve the effect of improving safety and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

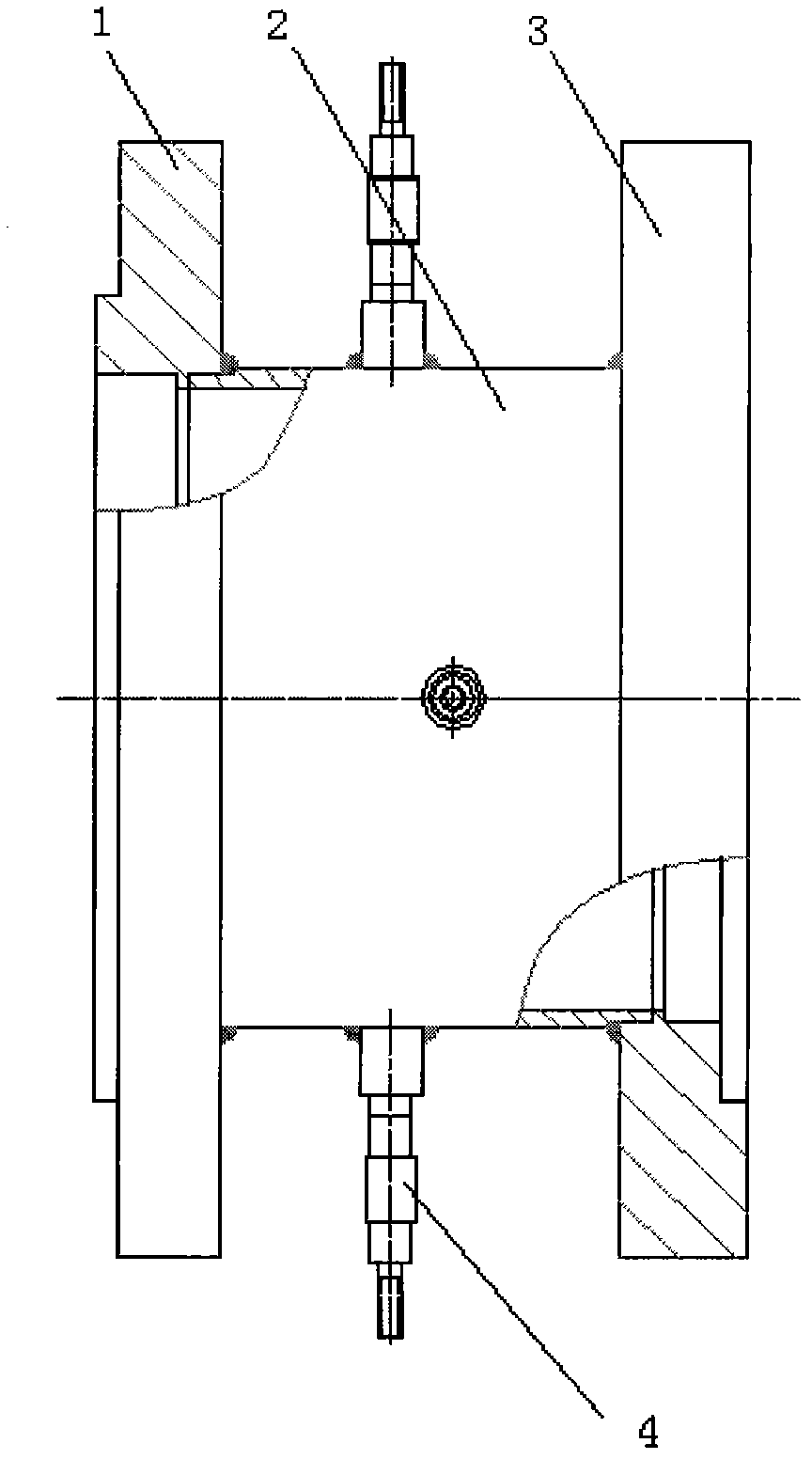

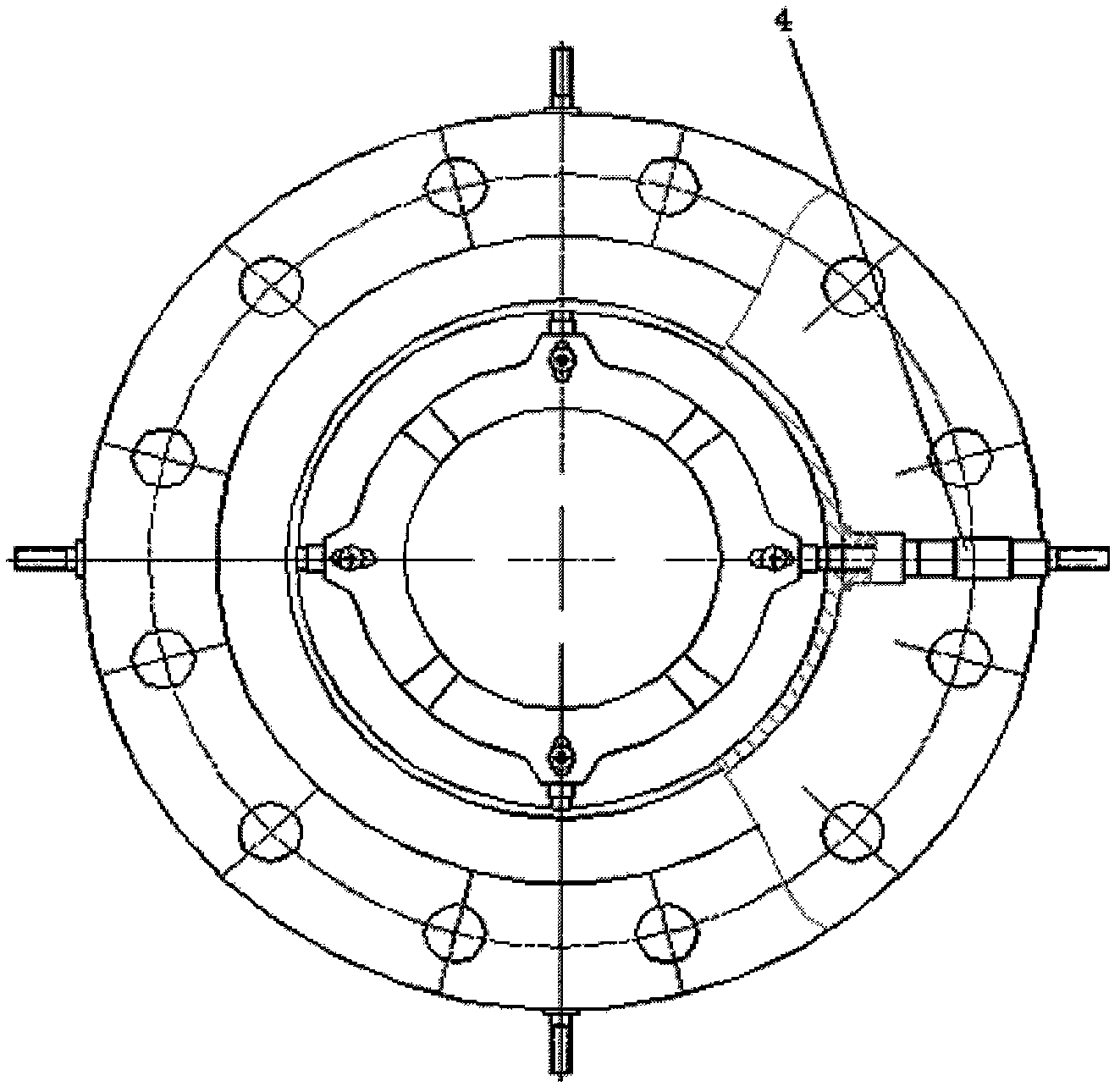

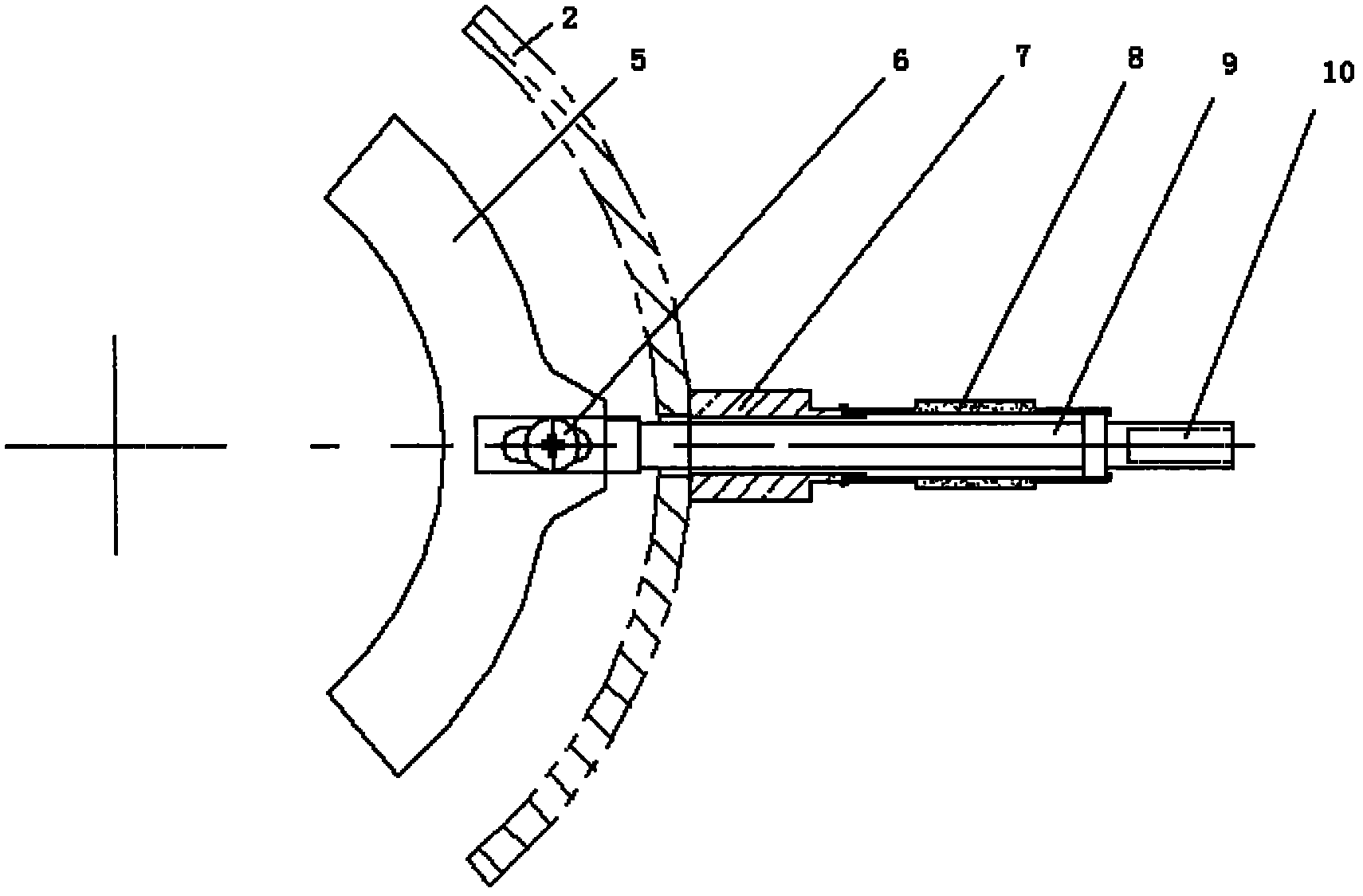

[0016] Below in conjunction with accompanying drawing, take the electron accelerator electron beam current monitoring device of four probes as example, describe the present invention in detail, as shown in the figure, pipeline 2 two sides are respectively welded with lower flange 1 and upper flange 3, and probe 4 is made of The stainless steel receiving plate 5, joint 7, Kovar insulating sleeve 8, and shaft 9 are composed. The receiving plate 5 is installed on the end of the shaft 9 inserted into the pipe through the screw 6. The joint 8 is set on the shaft 9 and connected to the outer wall of the pipe 3. Welding and fixing, the Kovar insulating sleeve 8 is set on the shaft rod 10, one end of which is welded with the joint 8, and the other end is welded with the shaft rod 9. The four probes 4 are evenly arranged in the circumferential direction on the same vertical plane inside the pipeline 2 . When the device is used, the upper flange 3 and the lower flange 1 are respectively...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com