System for controlling variable geometry apparatuses of a gas turbine engine particularly comprising a barrel link

A gas turbine and engine technology, which is applied in gas turbine devices, mechanical equipment, engine components, etc., can solve the problems of increased risk of engine flameout and large drawbacks.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

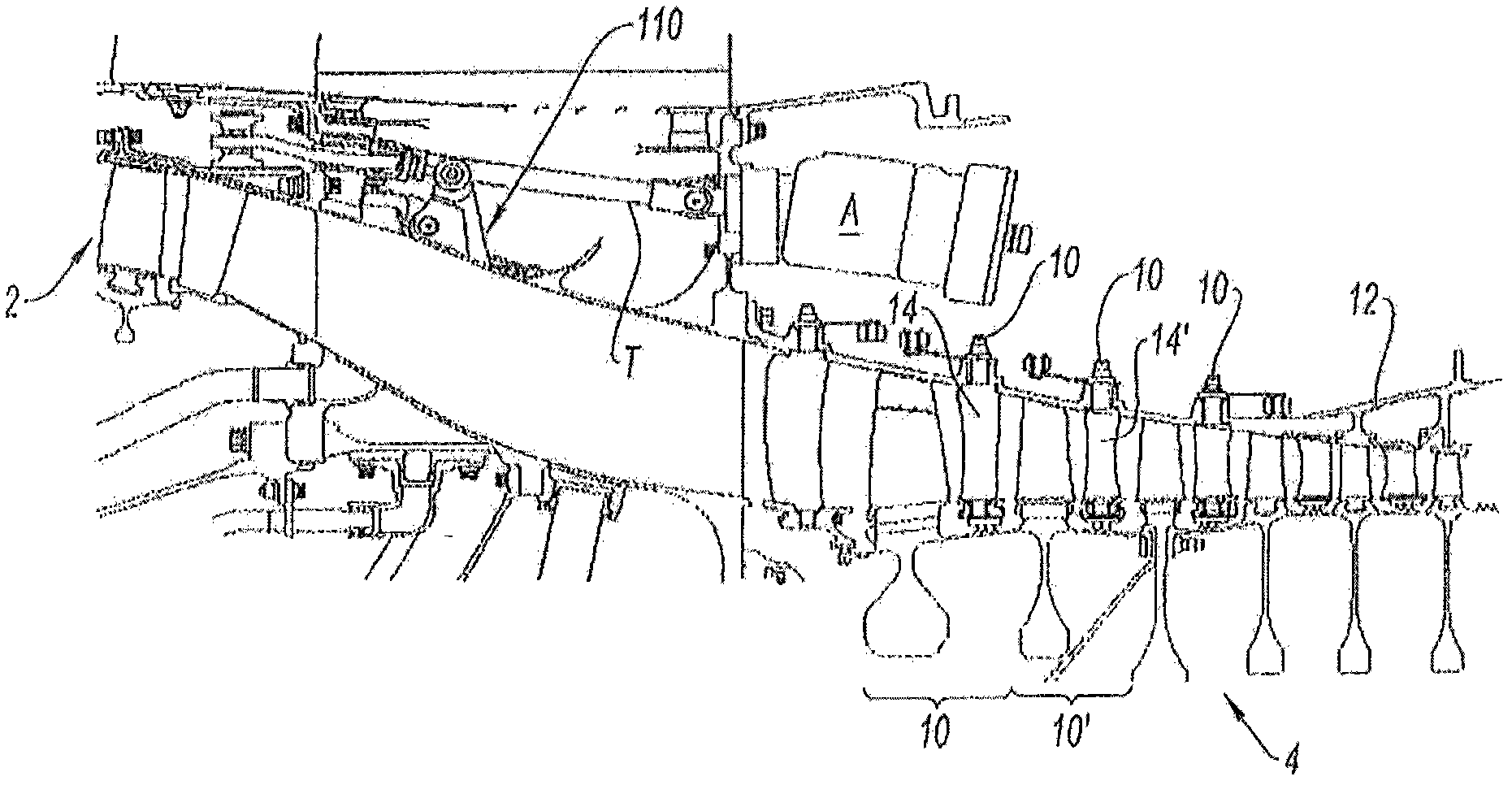

[0056] well known, such as figure 1 and figure 2 As shown, a gas turbine engine suitable for the aerospace field, such as a jet engine (represented by the X-X axis here), includes a fan, a low-pressure compressor 2, a high-pressure compressor 4, a combustor, a high-pressure turbine, and a low-pressure turbine from upstream to downstream and nozzles for injecting gas (not shown in the figure). The compressor and the high-pressure turbine are firmly fixed to the same shaft, called the high-pressure shaft, and thus belong to the high-pressure body of the engine or the first body that rotates at the first speed, while the low-pressure compressor and the low-pressure turbine are firmly fixed to the same shaft shaft, called the low-pressure shaft, and therefore belongs to the low-pressure body of the engine or the second body rotating at the second speed.

[0057] In the following, the abbreviations LP and HP denote low pressure and high pressure, respectively.

[0058] The high...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com