Synthesis method and application of a metal-organic framework material with a chiral hollow structure

A technology of organic framework and synthesis method, applied in organic chemistry methods, preparation of organic compounds, organic chemistry, etc., can solve the problems of low material porosity, reduced catalytic activity, reduced degree of freedom of chiral active molecules, etc., and achieve good application Prospect, the effect of accelerating mass transfer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

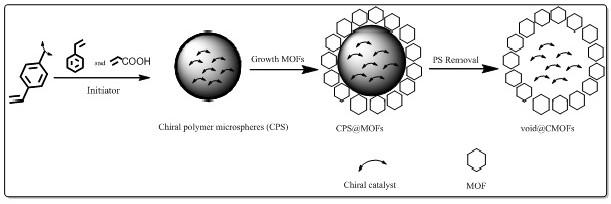

[0028] Such as figure 1 Shown, the present invention provides a kind of synthetic method of the metal-organic framework material of chiral hollow structure, comprising:

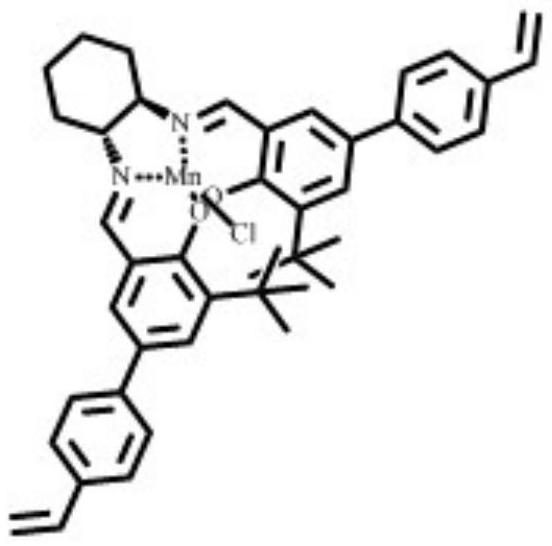

[0029] S10 prepares CPS (Chiralpolymer microspheres) from functionalized chiral salen-Mn(III) molecules, styrene and acrylic acid. Specifically, first, weigh functionalized chiral salen-Mn(III) molecules, styrene, acrylic acid, polyvinylpyrrolidone (PVP) and azobisisobutyronitrile (AIBN) in a certain mass ratio, wherein the functionalized Chiral salen-Mn(III) molecule, styrene and acrylic acid as raw materials, polyvinylpyrrolidone as dispersant, azobisisobutyronitrile as initiator, and functionalized chiral salen-Mn(III) molecule, styrene The mass ratio of polyvinylpyrrolidone, azobisisobutyronitrile and styrene is 2 to 3:50:5, and the mass ratio of acrylic acid is 3 to 10:1 to 2:80; the functionalized chiral salen-Mn( III) The molecular structure diagram is as follows:

[0030]

[0031] After that, ad...

Embodiment 1

[0036] Take 240 mg (mg) of functionalized salen Mn (III) chiral molecules, 4 mL (milliliters) of styrene, and 0.4 mL of acrylic acid, mix them, add them to a mixed solvent of 20 mL of deionized water and 40 mL of methanol, add 50 mg of initiator AIBN, 300 mg of PVP . Access to N 2 , heated at 70° C. for 12 hours with magnetic stirring, centrifuged, washed three times with absolute ethanol, and dried to obtain CPS microspheres.

[0037] Take 300 mg of CPS microspheres and ultrasonically disperse them uniformly in 120 mL of methanol, add 1.2 g of organic ligand 2-methylimidazole under the condition of magnetic stirring, and add 300 mg of zinc nitrate hexahydrate to methanol drop by drop with a constant pressure dropping funnel within 5 minutes. The solution was 10 mL, reacted at room temperature for 12 h, centrifuged, washed with methanol three times, and dried in vacuum at 60 °C to obtain CPS@MOFs.

[0038]Grind CPS@MOFs evenly, add 10mL DMF solvent, and dissolve at room temp...

Embodiment 2

[0043] Take 160 mg of functionalized salen Mn(III) chiral molecules, 4 mL of styrene, and 0.38 mL of acrylic acid, mix them, add them to a mixed solvent of 10 mL of deionized water and 20 mL of methanol, add 50 mg of initiator AIBN, and 300 mg of PVP. Access to N 2 , heated at 70° C. for 12 hours with magnetic stirring, centrifuged, washed three times with absolute ethanol, and dried to obtain CPS microspheres.

[0044] Take 500 mg of CPS microspheres and ultrasonically disperse them in 280 mL of methanol, add 4 g of organic ligand 2-methylimidazole under the condition of magnetic stirring, and add 20 mL of methanol solution of 500 mg of zinc nitrate hexahydrate drop by drop with a constant pressure dropping funnel within 5 minutes , reacted at room temperature for 12 h, centrifuged, washed three times with methanol, and dried in vacuum at 60 °C to obtain CPS@MOFs.

[0045] Grind CPS@MOFs evenly, add 25mL DMF solvent, and dissolve at room temperature for 5 days, during which ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com