Device for analysing the surface of a substrate

A substrate and reference pattern technology, applied in the direction of using optical devices, measuring devices, analyzing materials, etc., can solve the problems of long measurement process time, time-consuming acquisition process, prolonging the time for smooth panels to stop, etc., to achieve low cost, reduce small size effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053] The figures are not drawn to scale for easier study.

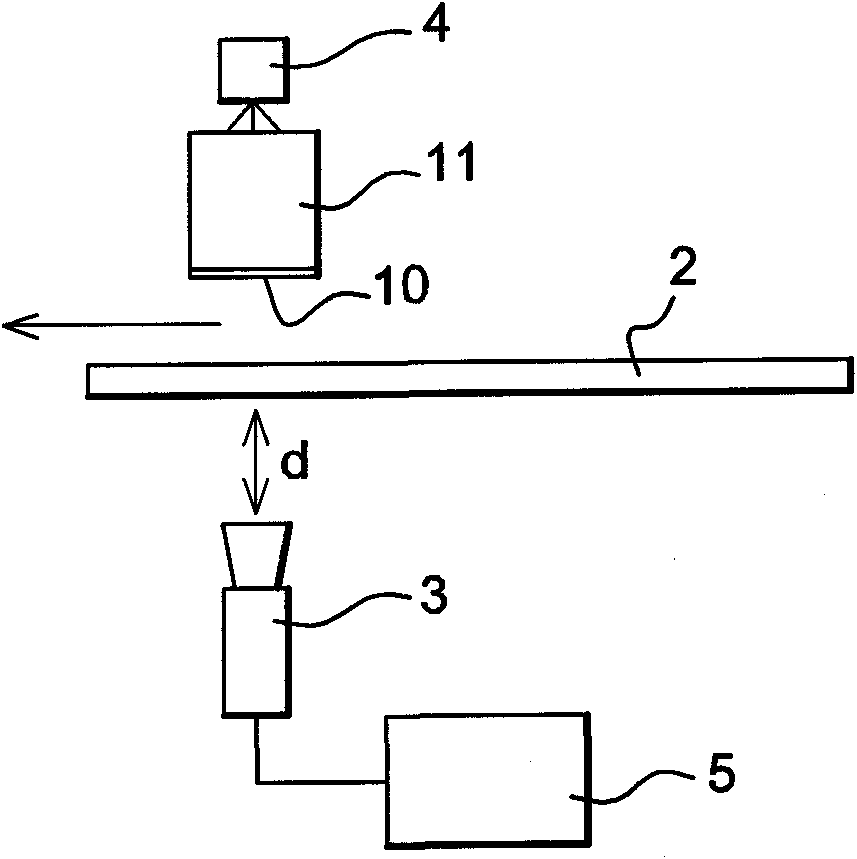

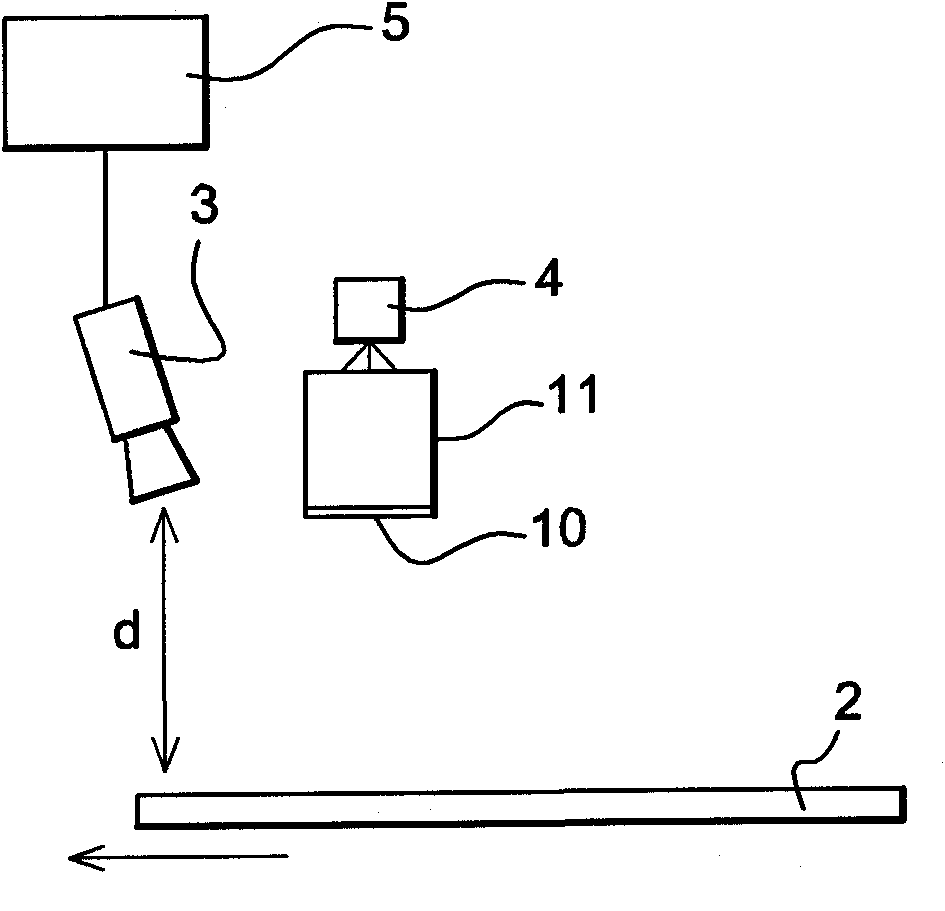

[0054] exist figure 1 with 2 The device 1 shown in allows the analysis of defects in a transparent substrate 2, eg a smooth panel, in transmission and in reflection, respectively. The device comprises a reference pattern 10 , image capture means 3 , eg a matrix camera, a reference pattern illumination system 4 and suitable processing / computing means 5 .

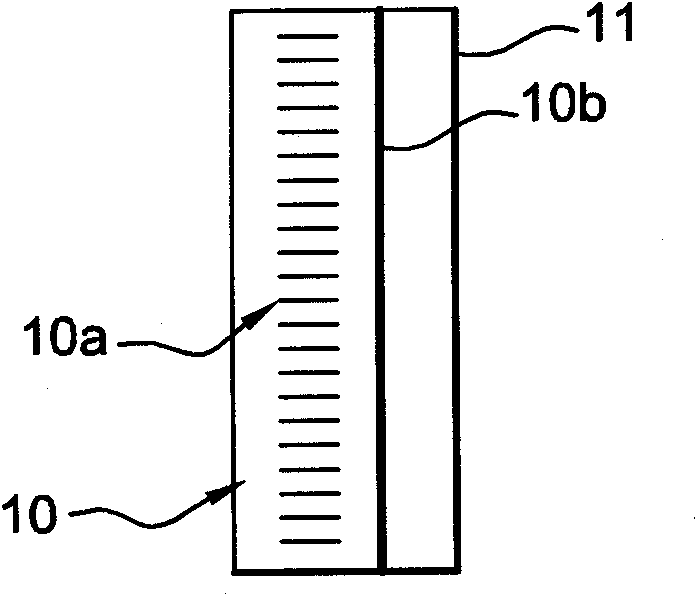

[0055] The reference pattern 10 is formed on one side of the support panel 11 facing the substrate to be measured. It will be described more fully later.

[0056] In transmission ( figure 1 ), the transparent substrate 2 is placed between the reference pattern 10 and the camera 3, and the objective lens of the camera points to the substrate.

[0057] In reflection ( figure 2 ), the substrate 2 with a mirror surface is placed in the front of the reference pattern 10 and the camera 3, the objective lens of the camera is in the same plane as that of the referen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com