X-ray tube anodes

An X-ray tube and anode technology, applied in the field of X-ray tubes, can solve the problems of complex and expensive anodes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

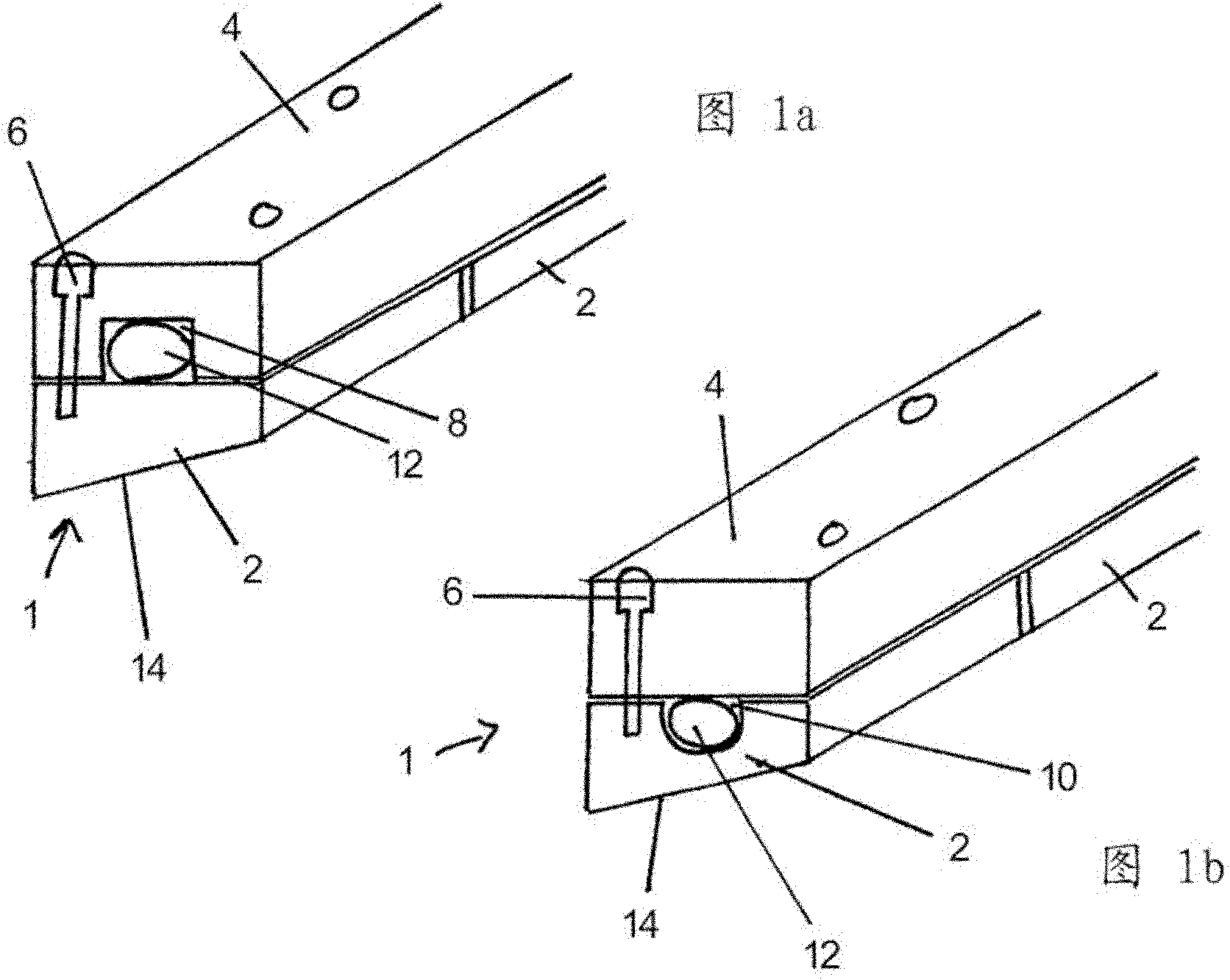

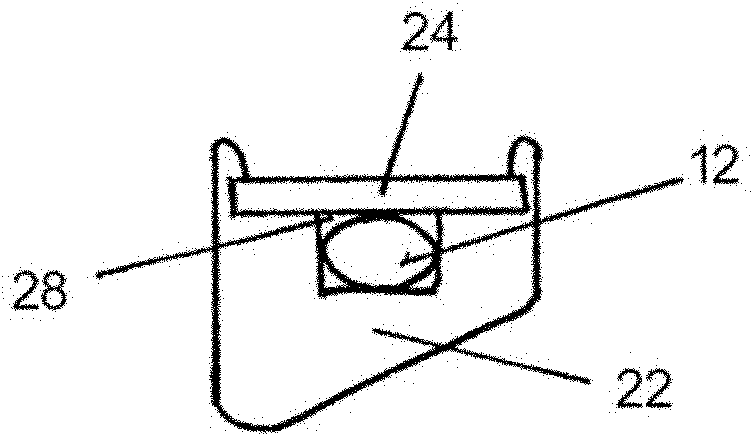

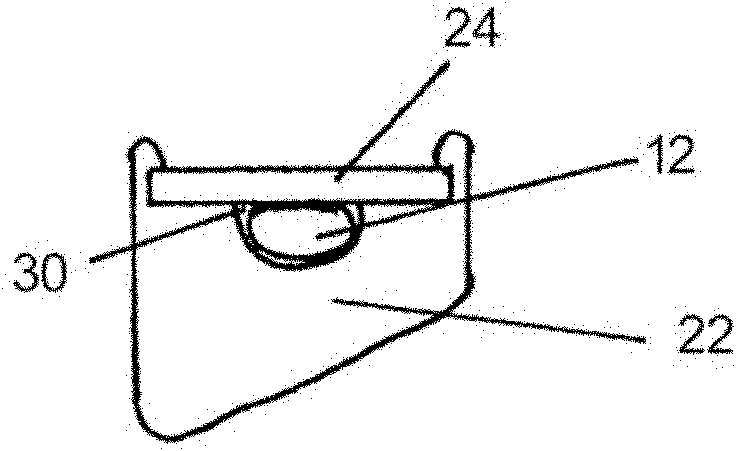

[0019] refer to Figure 1a , an anode 1 according to one embodiment of the invention comprises a plurality of thermally conductive anode segments 2 screwed by screws 6 to a rigid one-piece support member in the form of struts 4 . The cooling channels 8, 10 extend along the length of the anode between the anode segments and the struts and comprise coolant conduits arranged in the form of tubes 12 carrying cooling fluid.

[0020] Anode segment 22 is formed from a metal such as copper and is held at a high voltage positive potential relative to the electron source. Each anode segment 2 has an angled front surface 14 coated with a suitable target metal, such as molybdenum, tungsten, silver or uranium, chosen to generate the desired X-rays when electrons are incident thereon. This layer of target metal is applied to front surface 14 by one of a number of methods including sputter coating, electroplating deposition, chemical vapor deposition and combustion spray coating. Alternativ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com