Method for rolling welding line under automatic control

A roll gap and rolling mill technology, which is applied in the field of weld seam control in continuous cold rolling, can solve the problems of excessive thickness of the head and tail of the steel coil, and achieve the effect of improving the yield of finished products and reducing the rate of weld seam breakage.

Inactive Publication Date: 2012-12-12

PANGANG GROUP VANADIUM TITANIUM & RESOURCES +1

View PDF0 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0003] The purpose of the present invention is to overcome the shortcoming that the thickness of the head and tail of the steel coil is too long due to the current method of manually controlling the thickening of the weld, and to provide a method for automatically controlling the rolling of the weld

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment

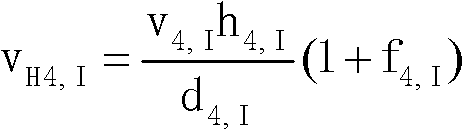

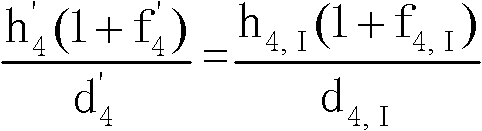

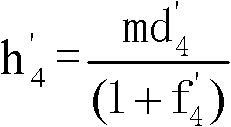

[0028] This example uses four racks as an example, and the racks are numbered from 1 to 4 in sequence.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention relates to the cold tandem rolling technology. The invention solves the problem that the thickness is seriously out of tolerance caused by the traditional manual control welding line thickening method and provides a method for rolling a welding line under automatic control. The technical scheme in the method can be summarized as follows: when the welding line passes through each rack, a gap between rollers and speeds of the rollers are changed by adopting an automatic control way, thus the welding line is thickened and the tensile force of strip steel is maintained to be constant. The method provided by the invention has the beneficial effects that the strip breakage rate of the welding line is reduced and the rate of finished products is improved, and the method is applicable to a cold tandem rolling machine set.

Description

technical field [0001] The invention relates to cold continuous rolling technology, in particular to the technology of welding seam control in cold continuous rolling. Background technique [0002] Weld strip breakage is a common production accident in tandem cold rolling mills. Weld strip breakage not only directly affects the operation rate of the unit and the yield rate of steel coils, but also easily causes damage to the roll surface and increases quality risks. In order to reduce the impact of weld seam breakage on Due to the adverse effects caused by the production of the cold tandem rolling mill, the main operator of the rolling mill had to take necessary thickening control measures for the welds of some specifications and steel types to reduce the unit tension that the welds bear when they pass through the rolling mill stand, thereby reducing the weld thickness. Seam broken strip rate, although this artificially controlled rolling mode or method has achieved a certai...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): B21B37/00B21B37/58B21B37/46B21B37/48

Inventor 刘挺

Owner PANGANG GROUP VANADIUM TITANIUM & RESOURCES

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com