Method and equipment for collecting, hoisting, compacting and transporting refuse

A technology for collecting garbage and garbage, applied in the direction of trash cans, garbage collection, garbage receptacles, etc., can solve the problems of easily damaged bucket lids, inconvenient use, poor working environment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

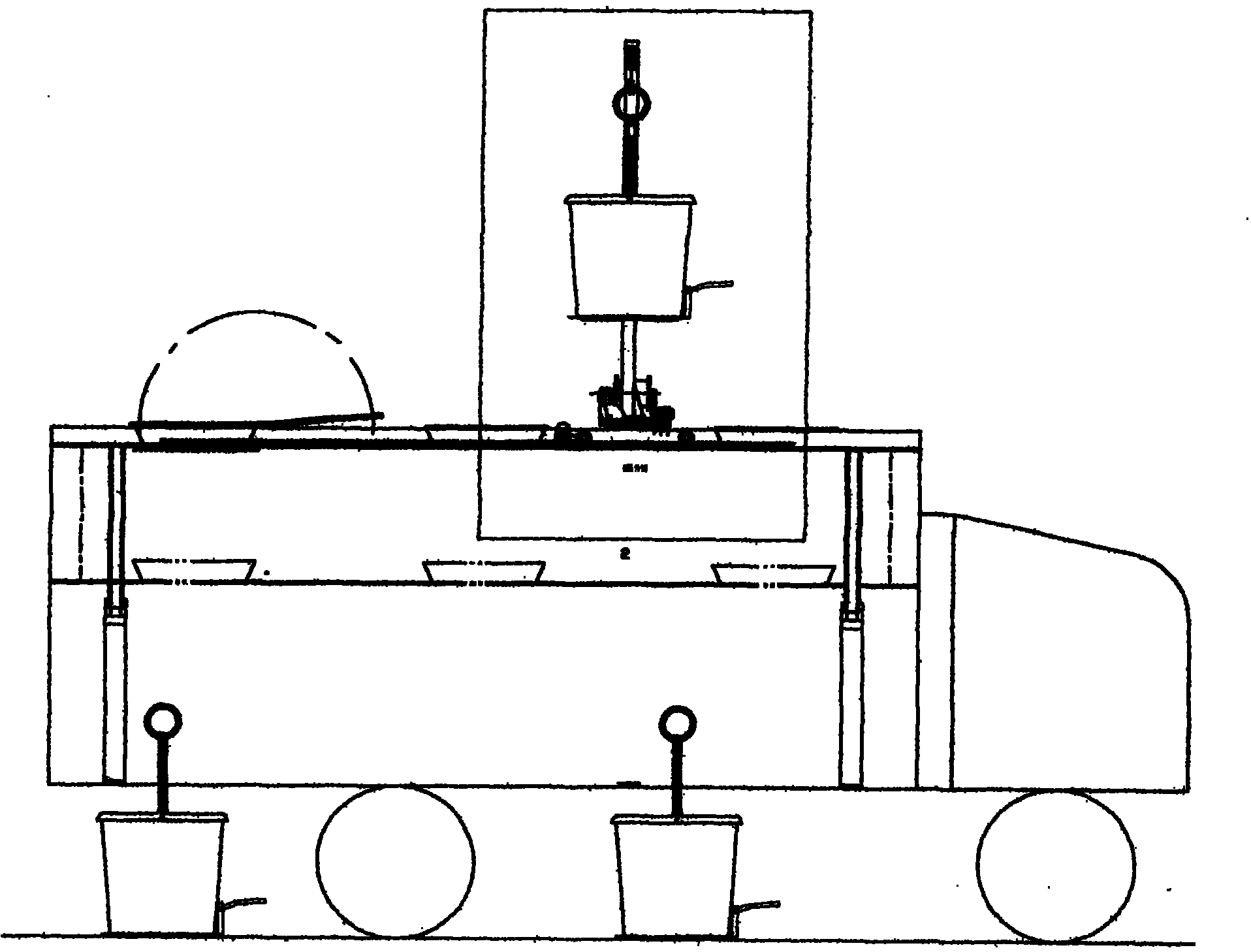

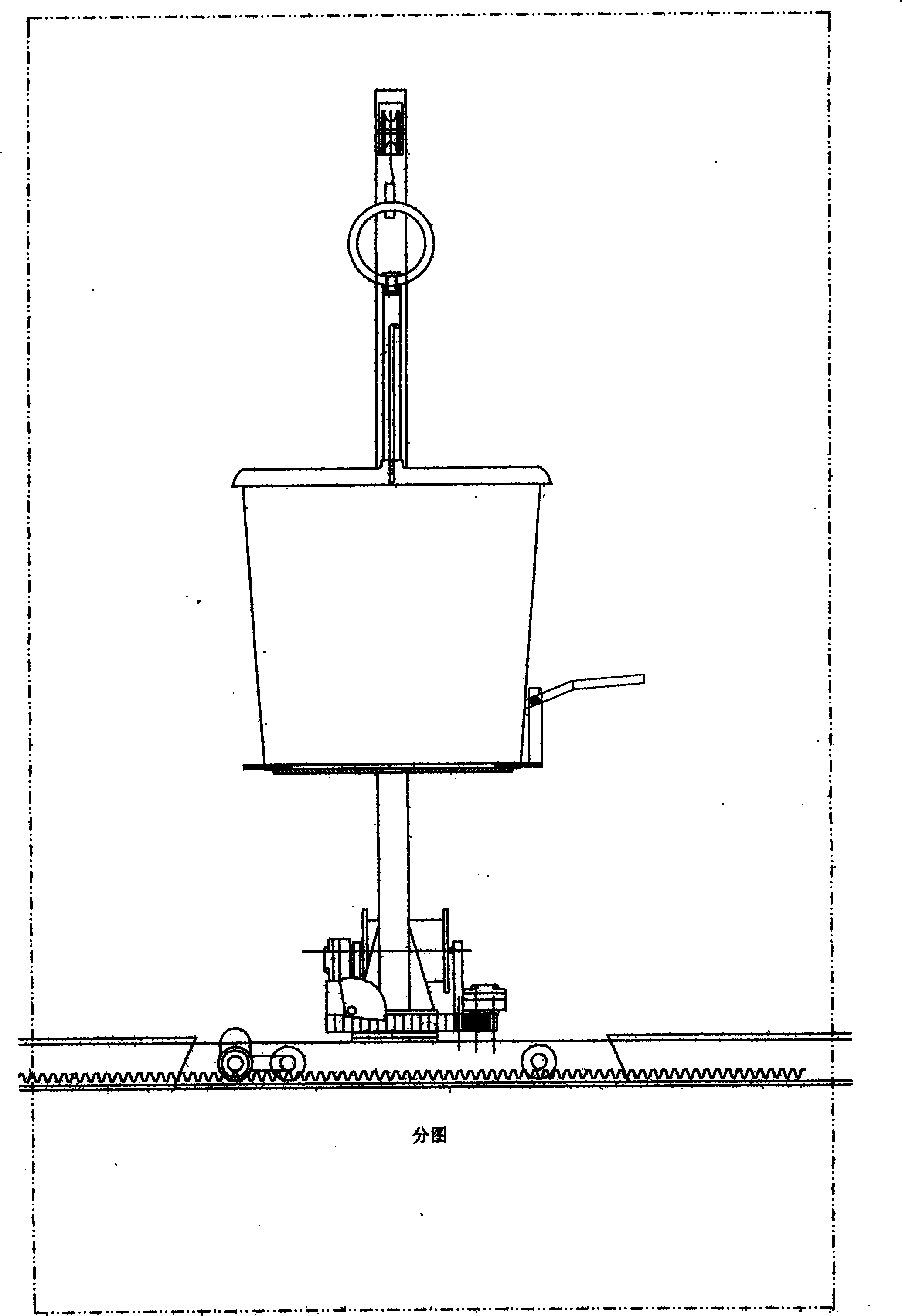

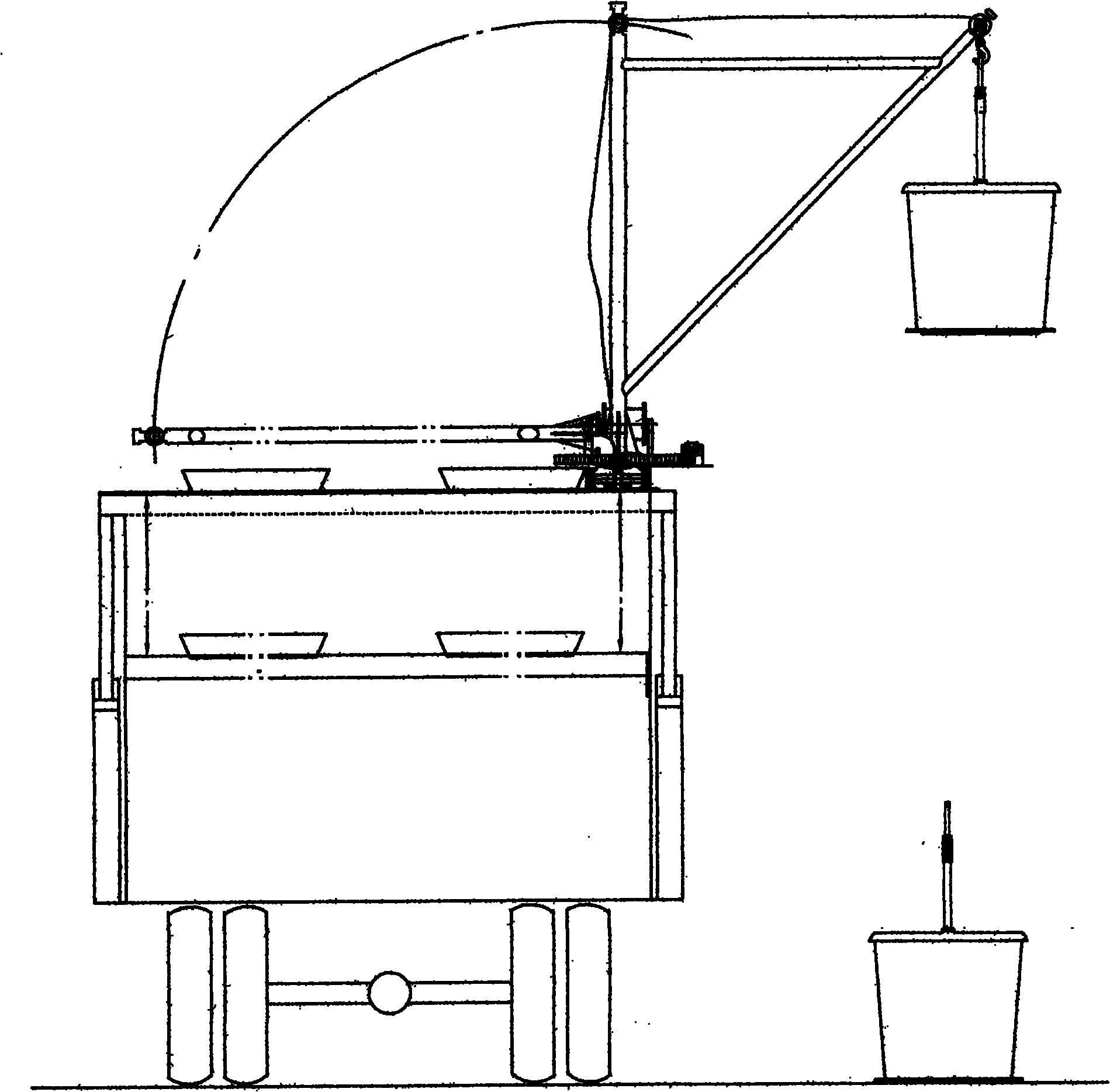

[0041] The preferred way to realize the method of the present invention is: (1) in combination with the municipal construction planning, reasonably set the distribution and placement locations and quantity of the self-unloading barrels, plan the route for collecting garbage, and collect garbage at fixed points at regular intervals.

[0042] (2) Ancillary equipment is set in a certain proportion and quantity. For example, each set of equipment is equipped with one dump truck of two types, large and small. Large trucks collect garbage from spacious roads, and small trucks collect garbage from small streets and alleys. 500 dump barrels and 10 cranes.

[0043] (3) In order to improve the transportation efficiency, the volume of the dump truck compartment should be made as large as possible so that more garbage can be loaded. The volume is 2 x 1.2 x 1.3 cubic meters.

[0044] (4) Based on the inventive method, formulate operating rules and industry standards for sanitation workers...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com