High-temperature steam biological wastewater inactivation system

A high-temperature steam and waste water technology, applied in the direction of heating water/sewage treatment, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc., can solve the problem of increasing equipment investment cost and equipment failure probability, increasing heat exchanger devices , waste water discharge increase and other issues, to achieve the effect of strong adaptability, high safety factor, advanced control system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

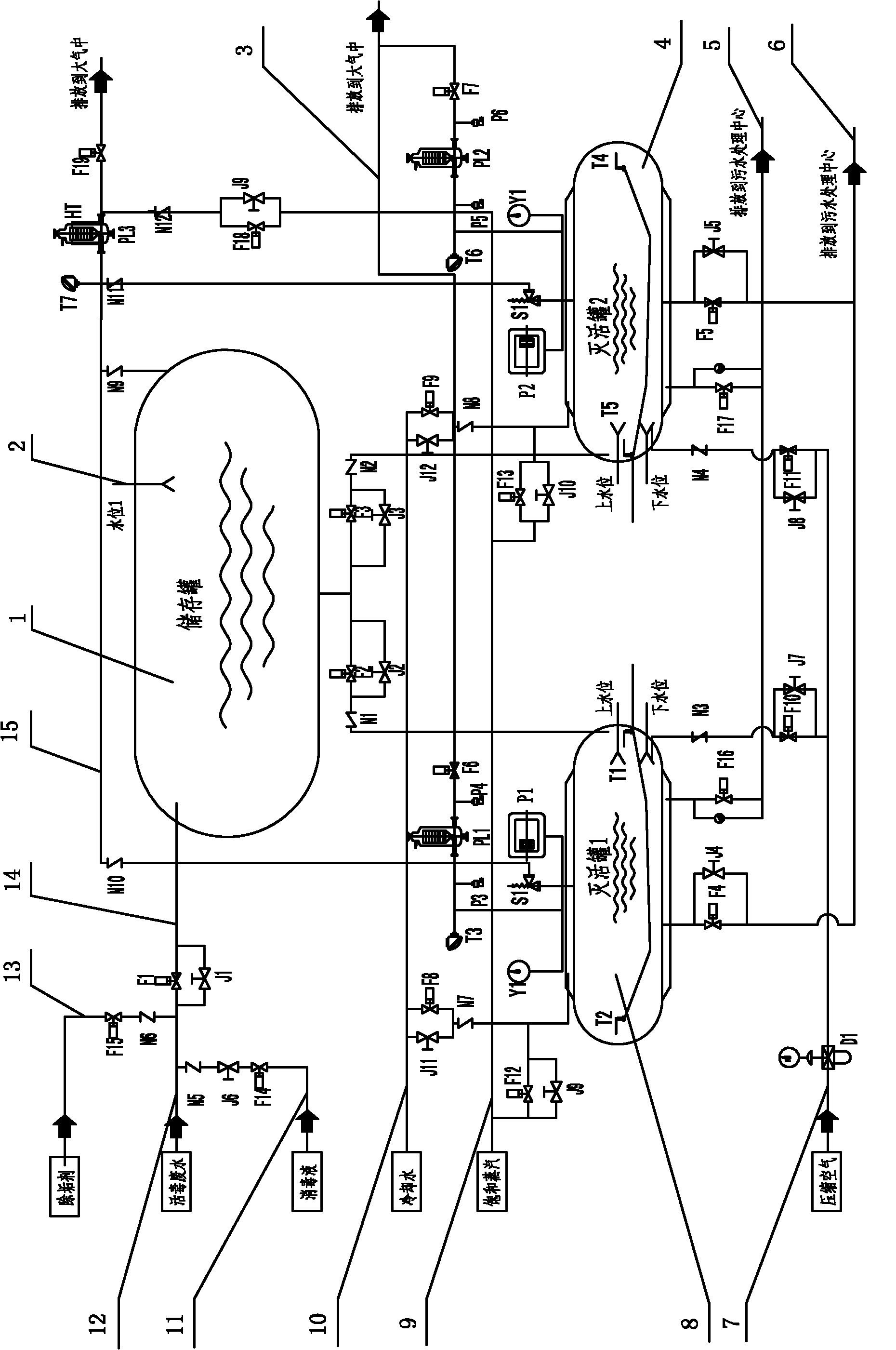

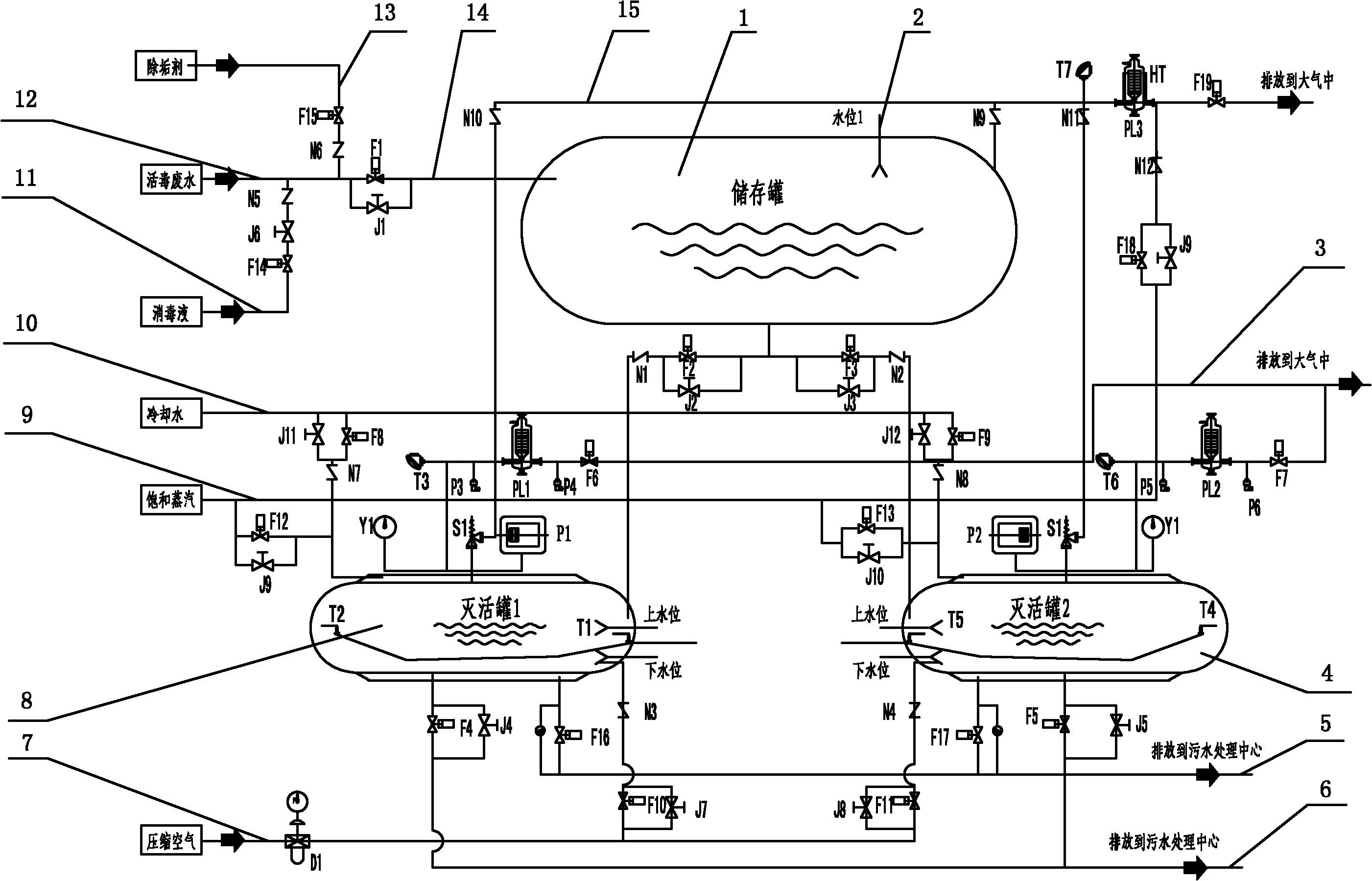

[0027] Such as figure 1 As shown, the waste water holding device 12, the storage tank 1 and the deactivation tank 4 are connected in series through pipelines, the deactivation tank 4 is provided with an exhaust pipe 15 and an inactivation drain pipe 6, and the outlet at the bottom of the storage tank 1 is connected to the two outlets through connecting pipes. A deactivation tank 4,8, the deactivation tank 4,8 is provided with a jacket, the input end of the jacket is connected to the saturated steam generator through the steam inlet pipe 9, the output end of the jacket is provided with a jacket steam discharge pipe 3, and the storage tank 1 The water inlet pipe 14, connecting pipe, exhaust pipe 15 and the steam inlet pipe 9 of the deactivation tank 4,8, the jacket steam discharge pipe 3, and the deactivation drain pipe 6 are respectively provided with pneumatic valves, and the pneumatic valves are connected to the control device to control The device controls the sequential bat...

Embodiment 2

[0041] On the basis of Embodiment 1, an electric heating system is arranged in the inactivation tanks 4 and 8, and the electric heating system is electrically connected to the control device. When working, both steam heating and electric heating can be used. An electric heating coil and an electric protection system are installed in the tank, which is electrically heated to a certain temperature and lasts for a certain period of time to complete the inactivation of the wastewater.

[0042] In the present invention, the original pipeline, waste water holding device, descaling agent device, disinfectant device, saturated steam generating device, cooling water and compressed air device, as well as heating system and control system are common prior art, and its setting and use Mastered by technicians in this industry.

[0043] Working principle and usage process:

[0044] Processing principle:

[0045] Thermal sterilization mainly uses high temperature to denature or coagulate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com