Unsaturated polyester resin for die pressing and preparation method thereof

A polyester resin and unsaturated technology, applied in the field of unsaturated polyester resin for molding and its preparation, can solve the problems of low heat resistance, poor surface smoothness of products, micro-cracks, etc. The effect of improving the surface finish

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

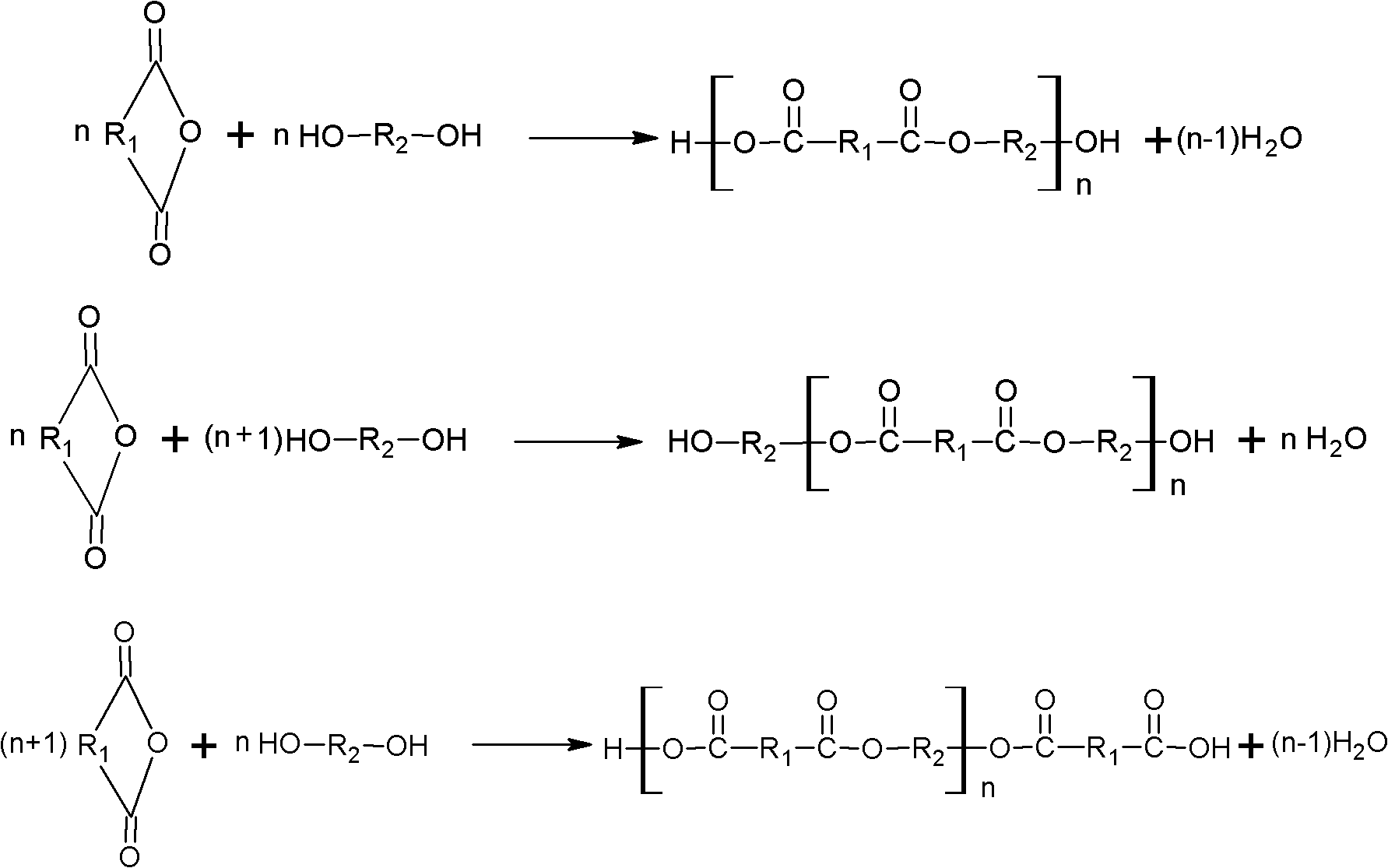

Method used

Image

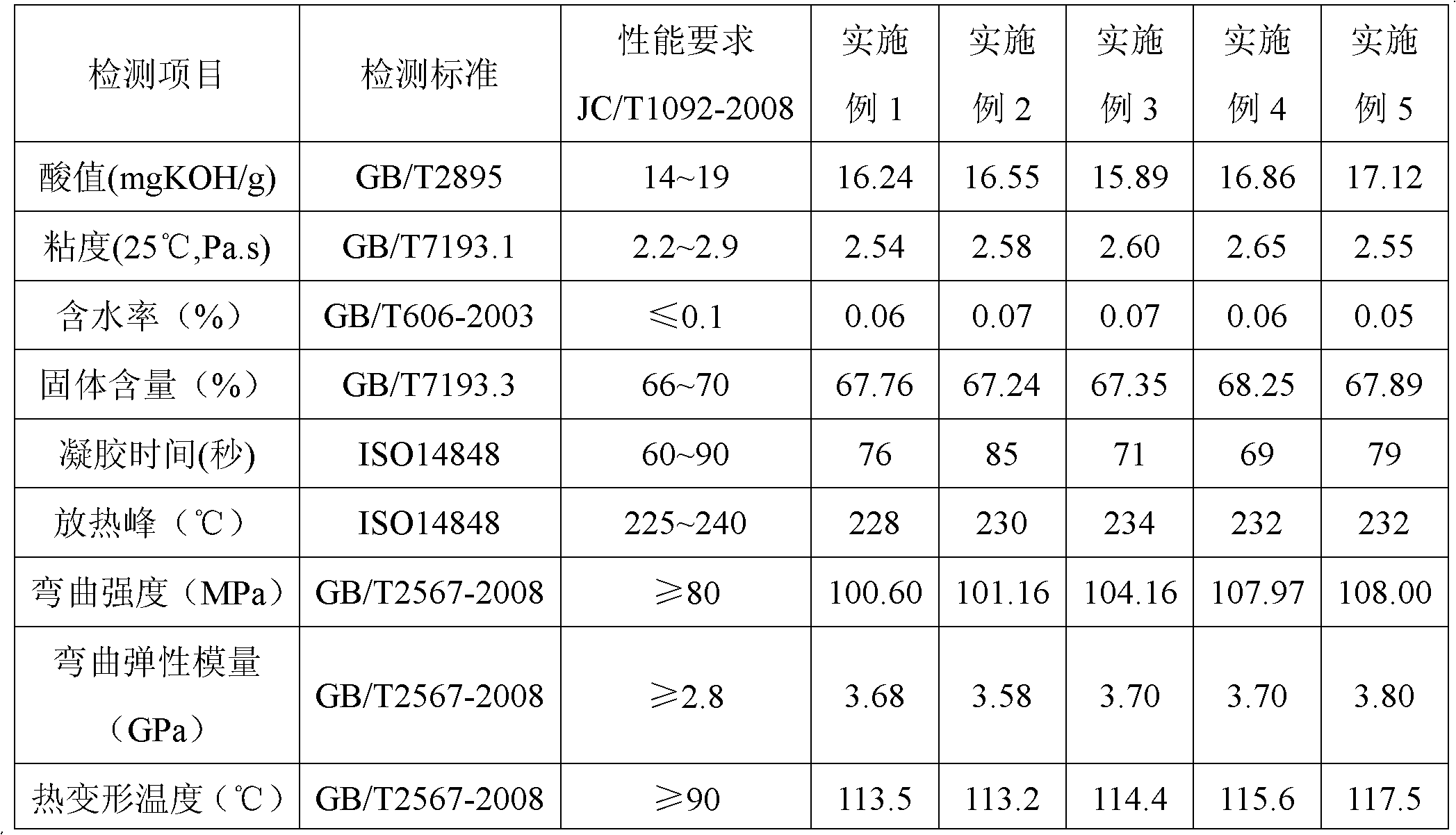

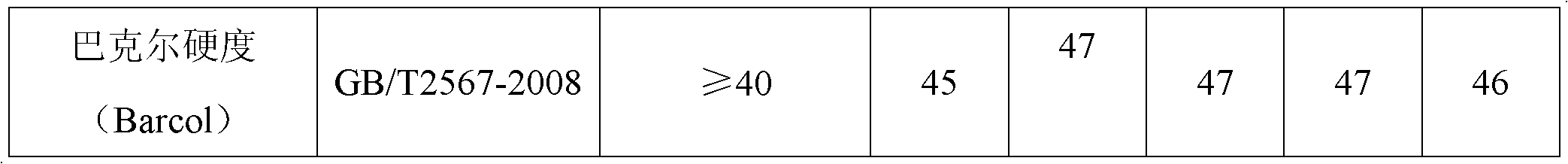

Examples

Embodiment 1

[0034] Formula: 150 parts by weight of phthalic anhydride, 290 parts by weight of propylene glycol, 440 parts by weight of maleic anhydride, 99 parts by weight of dipropylene glycol, 40 parts by weight of methylpropanediol, 85 parts by weight of neopentyl glycol, and 420 parts by weight of styrene.

[0035] Preparation:

[0036] a) Take 31% of the weight of propylene glycol, add phthalic anhydride under stirring state, seal it, and heat it to 197° C. for 4-5 hours.

[0037] b) When the acid value of the material reaches 60-65mgKOH / g, cool to 165°C, add the remaining propylene glycol, dipropylene glycol, methyl propylene glycol, and neopentyl glycol under stirring, stop stirring, and then add maleic anhydride; reheat the material When the temperature reaches 140°C, start stirring, heat to effluent for 6 hours, and when the temperature of the material rises to 210°C, keep it warm for 4 hours. When the acid value reaches 60-65mgKOH / g, vacuumize and reduce pressure. When the acid...

Embodiment 2

[0040] Formula: 120 parts by weight of phthalic anhydride, 350 parts by weight of propylene glycol, 470 parts by weight of maleic anhydride, 70 parts by weight of dipropylene glycol, 50 parts by weight of methylpropanediol, 70 parts by weight of neopentyl glycol, and 470 parts by weight of styrene.

[0041] Preparation:

[0042] a) Take 40% of the weight of propylene glycol, add phthalic anhydride in a stirring state, seal it, and heat it to 200° C. for 4 to 5 hours.

[0043] b) When the acid value of the material reaches 60-65mgKOH / g, cool to 170°C, add the remaining propylene glycol, dipropylene glycol, methyl propylene glycol, and neopentyl glycol under stirring, stop stirring, and then add maleic anhydride; reheat the material When the temperature reaches 150°C, start stirring, heat until the water comes out for 5 hours, and when the temperature of the material rises to 205°C, keep it warm for 5 hours. When the acid value reaches 60-65mgKOH / g, vacuumize and reduce pressure. ...

Embodiment 3

[0046] Formula: 145 parts by weight of phthalic anhydride, 317 parts by weight of propylene glycol, 445 parts by weight of maleic anhydride, 98 parts by weight of dipropylene glycol, 40 parts by weight of methylpropanediol, 80 parts by weight of neopentyl glycol, and 435 parts by weight of styrene.

[0047] Preparation:

[0048] a) Take 25% of the weight of propylene glycol, add phthalic anhydride in a stirring state, seal it, and heat it to 192° C. for 4-5 hours.

[0049] b) When the acid value of the material reaches 60-65mgKOH / g, cool to 160°C, add the remaining propylene glycol, dipropylene glycol, methyl propylene glycol, and neopentyl glycol under stirring, stop stirring, and then add maleic anhydride; reheat the material When the temperature reaches 145°C, start stirring, heat until the water comes out for 6 hours, and when the temperature of the material rises to 215°C, keep it warm for 4 hours. When the acid value reaches 60-65 mgKOH / g, vacuumize and reduce pressure. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| dielectric strength | aaaaa | aaaaa |

| heat deflection temperature | aaaaa | aaaaa |

| bending strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com