Method for testing flow conductivity of self-supported crack in riverfrac treatment

A technology for water fracturing and conductivity, which is applied in the directions of measurement, production of fluids, and earthwork drilling. Feasible, reliable in principle, simple in fabrication and test device structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

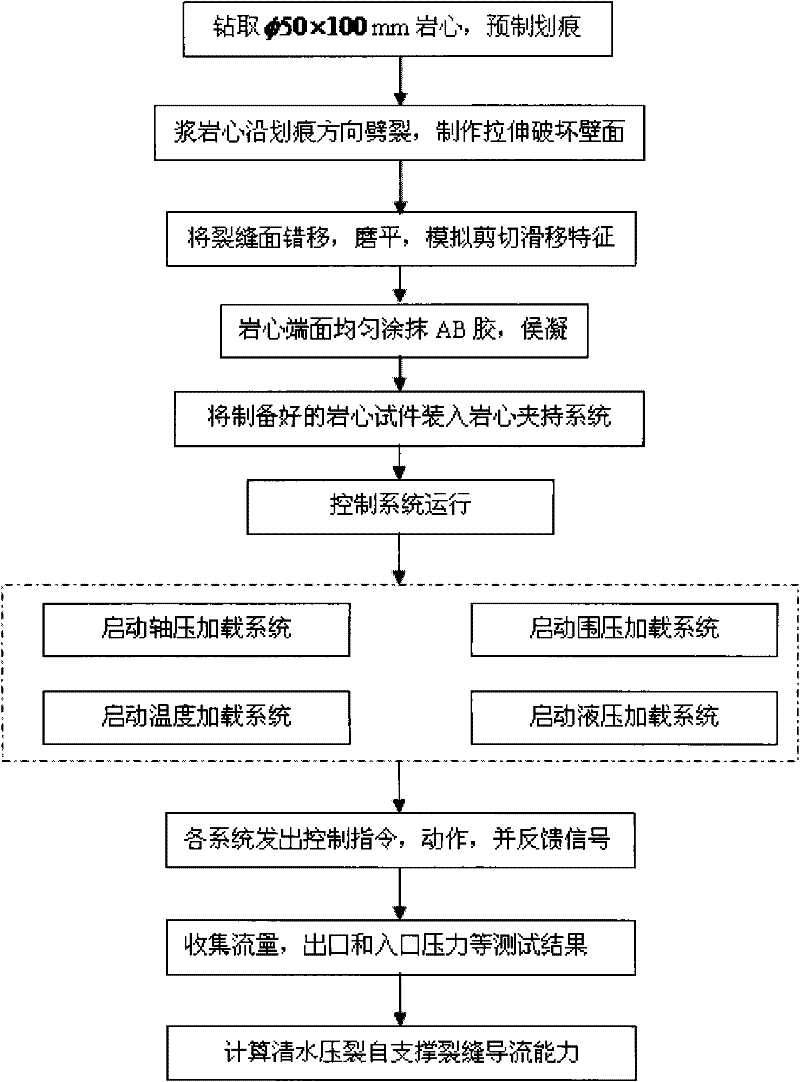

[0041] Firstly, a core specimen conforming to the closed form of the fracture wall surface after clear water fracturing and pressure relief is prepared, and the preparation method is as follows:

[0042] (1) Drill a cylindrical specimen of Φ50×100mm, bake it at a temperature of 105-110°C for 24 hours, and then put it in a desiccator to cool to room temperature.

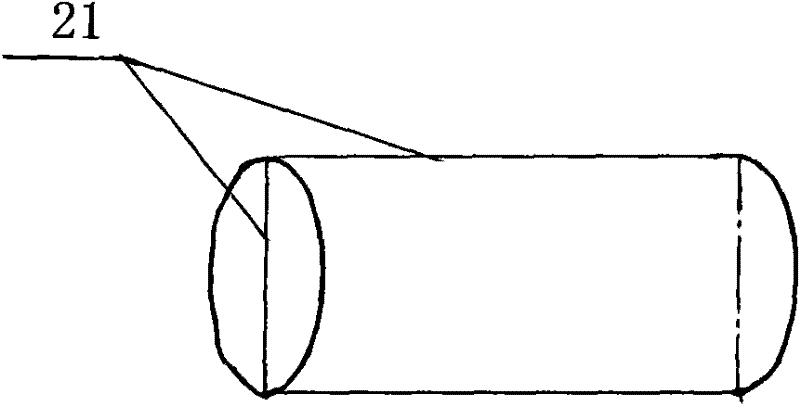

[0043] (2) Prefabricate scratches 21 orthogonally on the side of the rock core specimen in the direction along the axis and in the direction along the diameter of the end face, to induce the cracks to stretch and rupture along the direction of the scratches, and to obtain a relatively complete crack wall, see image 3 .

[0044] (3) Place the experimental core horizontally on the base of the splitter, adjust the position of the core so that the scratches in the axial direction of the core are directly below the triangular prism-shaped cemented carbide press knife, and the scratches on the end face along the diameter d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com