Large-flow liquid oxygen alcohol water vapor generator

A large flow, steam technology, applied in steam generation, steam generation methods, lighting and heating equipment, etc., can solve the problems of large, high cost, and complex steam generator systems, and achieve compact structure, low cost, and low investment. small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

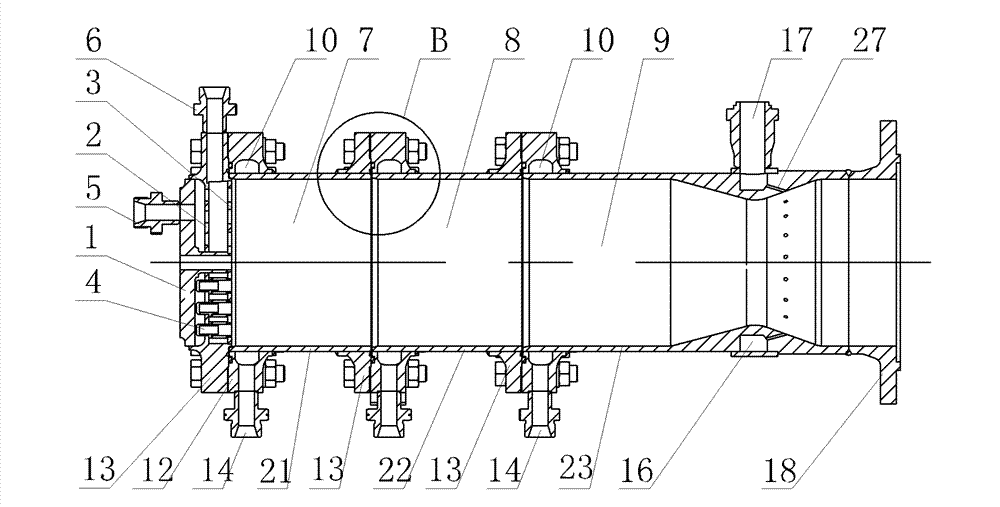

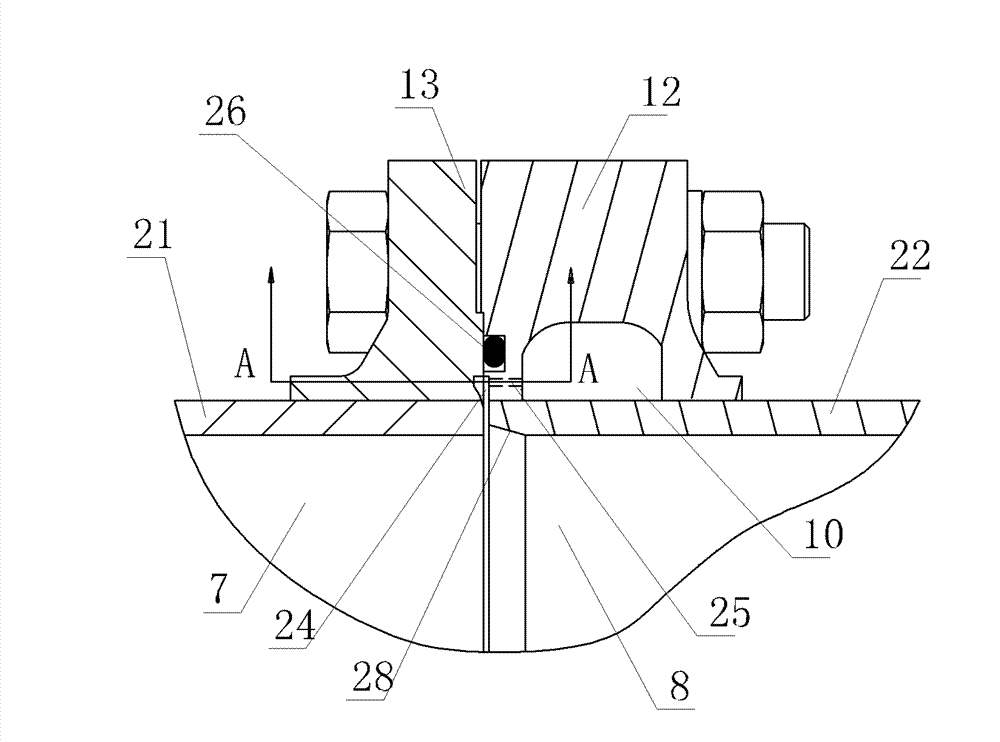

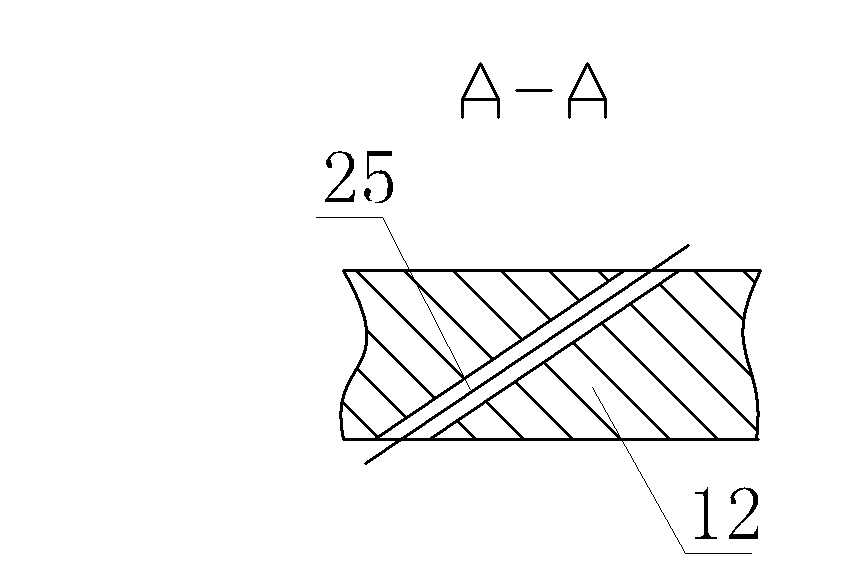

[0027] The large-flow liquid oxygen alcohol water vapor generator of the present invention includes a head and a body, the working medium is liquid oxygen, alcohol and water, and is ignited by an igniter specially arranged in the center of the head. The head includes an inner bottom 3, a midsole 2, an outsole 1, a liquid oxygen inlet nozzle 5, an alcohol inlet nozzle 6 and a plurality of nozzles 4 arranged in a concentric circle, forming an integral welding structure. The middle of the nozzle 4 is fixed on the midsole, the open end of the nozzle 4 is fixed on the inner bottom, and the opening of the nozzle 4 faces the body; the cavity between the inner bottom and the midsole constitutes an alcohol cavity, and the alcohol inlet nozzle 6 is connected to the alcohol The cavity is connected; the cavity between the midsole and the outsole constitutes a liquid oxygen cavity, and the liquid oxygen inlet nozzle 5 communicates with the liquid oxygen cavity; the liquid oxygen and alcohol ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com