Device for measuring damage threshold under combined action of three-wavelength pulse laser and debugging method

A technology of pulsed laser and co-action, applied in the direction of measuring devices, optics, optical components, etc., can solve the problems of different refraction offsets, deviations, and increased measurement errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

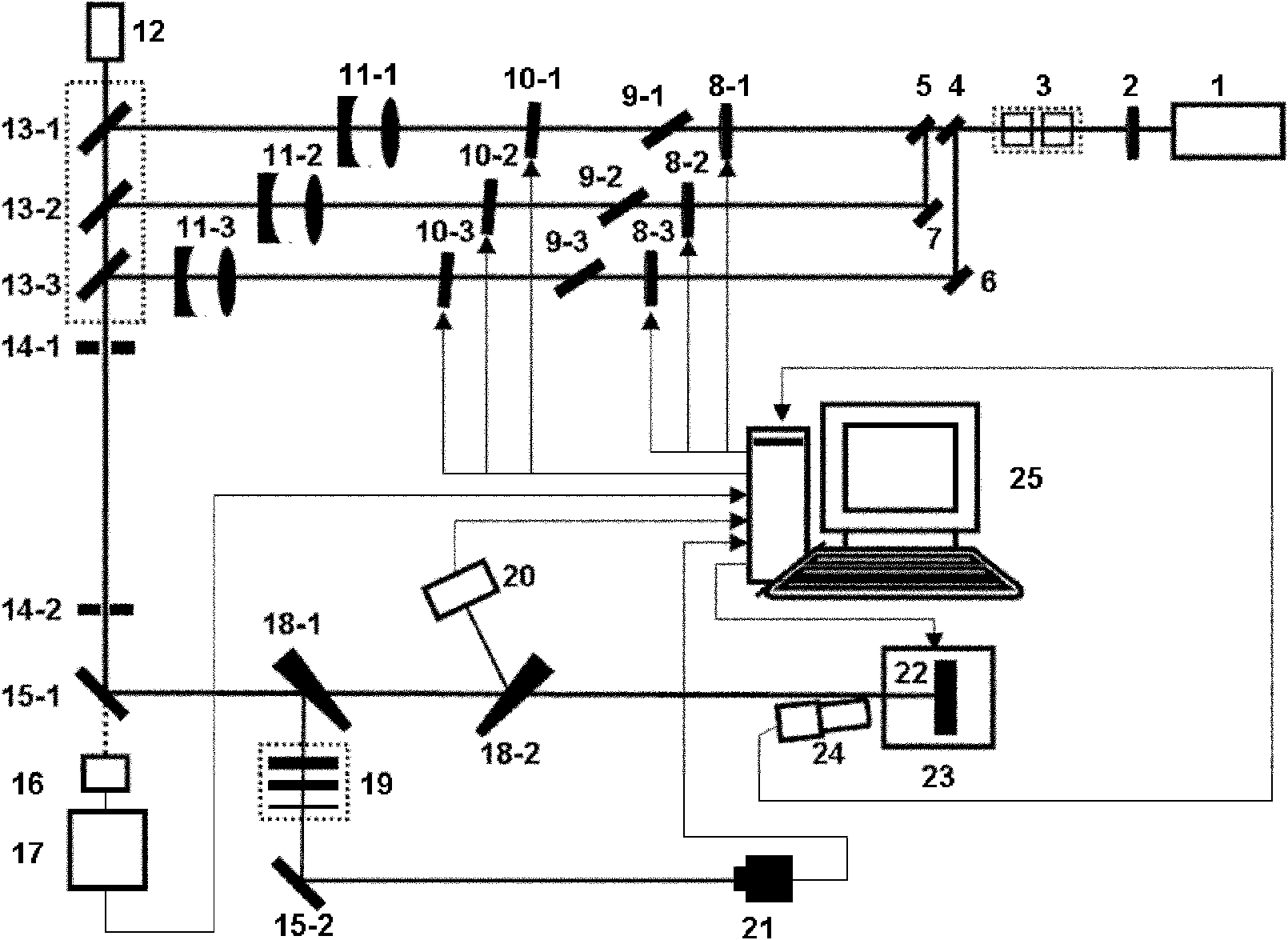

[0044] The present invention will be further described below in conjunction with the embodiments shown in the accompanying drawings.

[0045] refer to figure 1 , a damage threshold measurement device under the combined action of three-wavelength pulsed lasers,

[0046] It includes first lasers 1 sequentially arranged on the optical path to generate a fundamental frequency beam;

[0047] One-half wave plate 2, changing the vibration direction of the linearly polarized light of the fundamental frequency beam, adjusting the half wave plate 2 will change the frequency doubling and triple frequency of the fundamental frequency laser after the frequency doubling and frequency doubling crystal 3 Conversion efficiency, by adjusting the half-wave plate 2, the fundamental frequency, frequency-doubled and triple-frequency lasers with different maximum output energies can be obtained;

[0048] Frequency-doubling and triple-frequency crystal 3, the base frequency beam passes through the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com