Counter weight for liquid level float switch

A float switch, heavy hammer technology, applied in electrical switches, electrical components, circuits, etc., can solve the problems of inconvenient use and maintenance, poor fixing effect, weak adjustability, etc., to achieve easy use and maintenance, easy disassembly and Replaceable and easy-to-use effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments

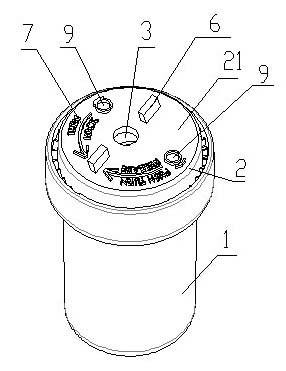

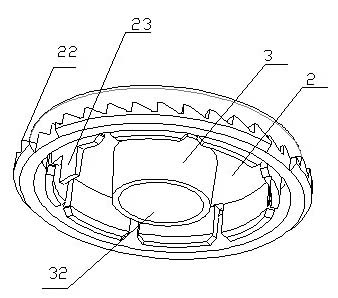

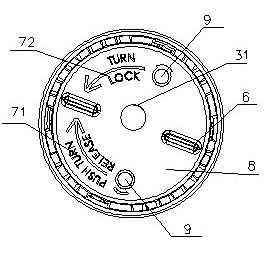

[0022] see figure 1 – Image 6 , a weight for a liquid level float switch, including a weight cup 1 and a weight cover 2, the top of the weight cup 1 and the weight cover 2 are rotatably fitted; one of the special features of the present invention is : The central part of the heavy hammer cover 2 is provided with a cover hollow column 3, the inside of the heavy hammer cup 1 is provided with a cup hollow column 4, and the two ends of the cover hollow column 3 are respectively provided with a cover eccentric hole 31 and matched with the cup hollow column 4 The center hole 32 of the cover, the cup hollow column 4 is provided with a cup eccentric hole 41 matching with the cover eccentric hole 31 , and at least one filler 5 is provided around the cup hollow column 4 . The cup eccentric hole 41 and the cover eccentric hole 31 loosen and cl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com