Bulk effect solar cell material and preparation method thereof

A solar cell and body effect technology, applied in circuits, electrical components, photovoltaic power generation, etc., can solve problems such as uneven particle distribution, high crystallization temperature, and complex process, and achieve high film quality, low growth temperature, and light absorption. good performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

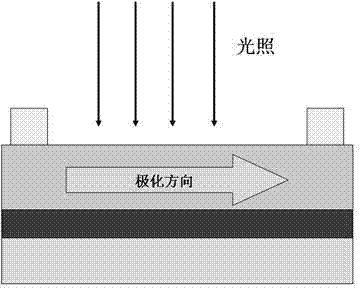

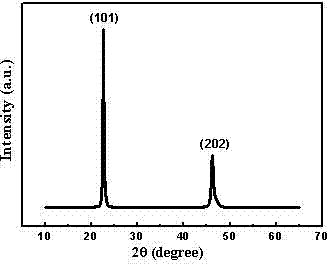

[0036] This example is in LaNiO 3 / Si substrate growth BiFeO 3 The preparation process of the bulk effect solar cell material and its photovoltage test.

[0037] 1. Thin film preparation

[0038] 1. Preparation of precursor solution. Ferric nitrate and bismuth nitrate powder were dissolved in glacial acetic acid, stirred at room temperature for 30 minutes, and the stirring speed was 600 rpm, so that ferric nitrate and bismuth nitrate were completely dissolved. Then add ethylene glycol to adjust the viscosity of the solution so that the solution concentration is 0.25mol / L. Stirring was continued at room temperature for 30 minutes at a stirring rate of 600 rpm. A dark red clear solution was obtained. The solution was aged for 72 hours to obtain bismuth ferrite sol. The resulting sol can be stored at room temperature for a long time.

[0039] 2. LaNiO 3 / Si substrates were sonicated in acetone, alcohol, and deionized water for 5 minutes.

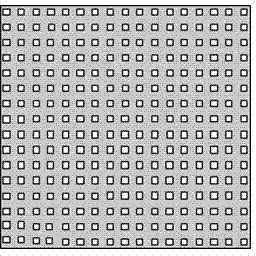

[0040] 3. glued. Spin-coat th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com